Abstract

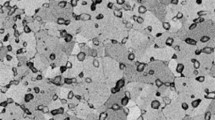

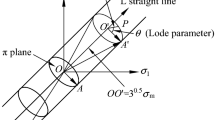

In this study, the Q* parameter was characterized to evaluate the Creep crack growth rate (CCGR) of type 316LN stainless steel. Creep crack growth (CCG) data were obtained by CCG tests under different applied loads at 600°C. An additional CCG test was conducted at 550°C to investigate the possible temperature dependence of the stress intensity factor. An equation using the Q* parameter for evaluating CCGR was proposed, and this parameter was characterized and compared with the typical C* fracture parameter, which is commonly used. The Q* parameter exhibited good linearity of the data, exhibiting no nonlinearity-induced dual value at the early stage. The Q* parameter was suitable for characterizing the CCGR regardless of different applied loads and types of steels. In addition, fracture microstructures near the crack revealed a typical intergranular fracture mode, and this fracture was dominantly propagated along the grain boundary. The cracks were developed by the growth and interlinking of cavities, which were attributed to the precipitates forming along the grain boundary.

Similar content being viewed by others

References

W. G. Kim, S. N. Yin, S. H. Kim, W. S. Ryu, C. B. Lee and S. J. Kim, A numerical approach to determine creep constants for time-temperature parametric methods, Met. Mater. Int., 15 (2009) 559–564.

W. G. Kim, S. H. Kim and W. S. Ryu, Creep characterization of type 316LN and HT-9 stainless steels by the K-R creep damage model, KSME International Journal, 15 (2001) 1463–1471.

W. S. Ryu, W. G. Kim and K. Y. Lee, Evaluation of creep crack growth behavior of type 316LN stainless steel, Trans. of The 17th International Conference Structural Mechanics in Reactor Technology, F05-4 (2003).

W. G. Kim, S. H. Kim and W. S. Ryu, Evaluation of Monkman-Grant parameters for type 316LN and modified 9Cr-Mo stainless steels, J. of Mechanical Science and Technology, 16 (2002) 1420–1427.

M. D. Mathew, Evaluation of creep resistant 316LN steel for sodium cooled fast reactor applications, Transaction of The Indian Institute of Metals, 63 (2010) 151–158.

V. Ganesan, M. D. Mathew, P. Parameswaran and K. Laha, Effect of nitrogen on evolution of dislocation substructure in 316LN SS during creep, Procedia Engineering, 55 (2013) 36–40.

M. D. Mathew, K. Laha and V. Ganesan, Improving creep strength of 316L stainless steel by alloying with nitrogen, J. of Material Science and Engineering A, 535 (2012) 76–83.

J. G. Kumar, V. Ganesan, K. Laha and M. D. Mathew, Time dependent design curves for a high nitrogen grade of 316LN stainless steel for fast reactor applications, J. of Nuclear Engineering and Design, 265 (2013) 949–956.

W. G. Kim, J. Y. Park, S. D. Hong and S. J. Kim, Probabilistic assessment of creep crack growth rate for Gr.91 steel, Nucl. Eng. and Design, 242 (2011) 3580–3586.

I. M. W. Ekaputra, W. G. Kim, J. Y. Park, S. J. Kim and Y. W. Kim, Analysis of the creep crack growth rate for modified 9Cr-1Mo steel using Q* parameter, J. of Mechanical Science and Technology, 28 (2014) 4075–4081.

A. T. Yokobori Jr., T. Yokobori, T. Nishihara and T. Yamaoka, An alternative correlating parameter for creep crack growth rate and its application: Derivation of the parameter Q*’, Materials at High Temperatures, 10 (1992) 108–118.

A. T. Yokobori Jr. and T. Yokobori, Comparative study on characterization parameters for high temperature creep crack growth with special emphasis on dual value behaviour of crack growth rate, Eng. Fract. Mech., 55 (1996) 493–503.

T. Yokobori, H. Sakata and A. T. Yokobori Jr., A new parameter for prediction of creep crack growth rate at high temperature, Eng. Fract. Mech., 13 (1979) 533–539.

A. T. Yokobori Jr., H. Tomizawa, H. Sakata, T. Kako and T. Kuriyama, Representation of the displacement rate between the loading points in terms of applied stress and temperature and its relation to creep crack growth rate, C*, P and Q* parameters, Eng. Fract. Mech., 28 (1987) 805–816.

T. Yokobori, C. Tanaka, K. Yagi, M. Kitagawa, A. Fuji, A. T. Yokobori Jr. and M. Tabuchi, Result of an intercomparison of creep crack growth tests made in japan, Materials at High Temperatures, 10 (1992) 97–107.

Y. Kaji, K. Kikuchi and A. T. Yokobori Jr., Estimation of creep fracture life for hastelloy XR by Q* parameter, Eng. Fract. Mech., 50 (1995) 519–528.

A. T. Yokobori Jr., T. Yokobori and T. Nishihara, Characterization of high temperature creep crack growth and creep life from high temperature ductile through to high temperature brittle materials, Eng. Fract. Mech., 40 (1991) 737–748.

ASTM E 1457-13, Standard test method for measurement of creep crack growth rates in metals (2013).

ASTM E08-01, Standard test method for tension testing of metallic materials (2001).

ASTM E21-09, Standard test method elevated temperature tension tests of metallic materials (2009).

ASTM E 139-07, Standard test method for conducting creep, creep rupture and stress rupture tests of metallic materials (2007).

M. E. Kassner and T. A. Hayes, Creep cavitation in metals, International Journal of Plasticity, 19 (2003) 1715–1748.

Author information

Authors and Affiliations

Additional information

Recommended by Editor Chongdu Cho

I Made Wicaksana Ekaputra is a Ph.D. candidate in the Department of Mechanical Design Engineering of Pukyong National University. He received a B.A. degree from Diponegoro University, Indonesia, in 2008 and a master’s degree in Engineering from Pukyong National University, Korea, in 2013. His main research interests include creep and creep crack growth behaviors at elevated temperatures.

Rights and permissions

About this article

Cite this article

Ekaputra, I.M.W., Kim, WG., Park, JY. et al. Characterization of the Q* parameter for evaluating creep crack growth rate for type 316LN stainless steel. J Mech Sci Technol 30, 3151–3158 (2016). https://doi.org/10.1007/s12206-016-0625-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0625-4