Abstract

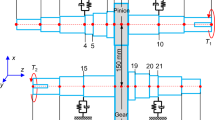

The frictional power loss issue of gear pairs becomes an important concern in both industry and academia due to the requirement of the energy saving and the improvement of power density of gear drives. A thermal starved elastohydrodynamic lubrication model is developed to study the tribological performance of a spur gear pair under starved lubrication conditions. The contact pressure, the film thickness, the temperature rise, the frictional power loss, as well as the coefficient of friction are evaluated by considering the variation of the curvature radius, the sliding/rolling motion, and the load distribution of gear tooth within the meshing period. Effects of lubrication starvation condition, load and speed on the coefficient of friction are studied.

Similar content being viewed by others

References

Y. Diab, F. Ville and P. Velex, Investigations on power losses in high-speed gears, Proceedings of the Institution of Mechanical Engineers Part J-J. of Engineering Tribology, 220 (2006) 191–198.

H. Liu, K. Mao, C. Zhu, X. Xu and M. Liu, Parametric studies of spur gear lubrication performance considering dynamic loads, Proceedings of the Institution of Mechanical Engineers, Part J: J. of Engineering Tribology, 226 (2012) 731–737.

C. Song, C. Zhu and W. Liu, Sliding friction effect on dynamics of crossed beveloid gears with small shaft angle, JMST, 27 (2013) 1255–1263, 2013/05/01.

J. A. Brandão, R. Martins, J. H. Seabra and M. J. Castro, An approach to the simulation of concurrent gear micropitting and mild wear, Wear, 324 (2015) 64–73.

K. L. Johnson, Contact mechanics, Cambridge University Press (1985).

T. T. Petry-Johnson, A. Kahraman, N. E. Anderson and D. R. Chase, An experimental investigation of spur gear efficiency, J. of Mechanical Design, 130 (2008) 062601–10.

C. M. C. G. Fernandes, P. M. T. Marques, R. C. Martins and J. H. O. Seabra, Gearbox power loss. Part III: Application to a parallel axis and a planetary gearbox, Tribology International (2015).

K. L. Johnson and D. I. Spence, Determination of gear tooth friction by disc machine, Tribology International, 24 (1991) 269–275.

P. M. Ku, H. E. Staph and H. J. Carper, Frictional and thermal behaviors of sliding-rolling concentrated contacts, J. of Lubrication Technology, 100 (1978) 121–128.

J. Castro and J. Seabra, Coefficient of friction in mixed film lubrication: gears versus twin-discs, Proceedings of the Institution of Mechanical Engineers Part J-J. of Engineering Tribology, 221 (2007) 399–411.

G. H. Benedict and B. W. Kelley, Instantaneous coefficients of gear tooth friction, ASLE Transactions, 4 (1961) 59–70, 1961/01/01.

B. W. Kelley and A. J. Lemanski, Lubrication of involute gearing, ARCHIVE: Proceedings of the Institution of Mechanical Engineers, Conference Proceedings 1964-1970 (vols 178-184), Various titles labelled Volumes A to S, 182 (1967) 173–184.

B. R. Höhn, K. Michaelis and T. Vollmer, Thermal rating of gear drives: Balance between power loss and heat dissipation, AGMA Technical Paper (1996) 12.

R. Martins, J. Seabra, A. Brito, C. Seyfert, R. Luther and A. Igartua, Friction coefficient in FZG gears lubricated with industrial gear oils: Biodegradable ester vs. mineral oil, Tribology International, 39 (2006) 512–521.

R. Larsson, Transient non-Newtonian elastohydrodynamic lubrication analysis of an involute spur gear, Wear, 207 (1997) 67–73.

A. Dyson, Frictional traction and lubricant rheology in elastohydrodynamic lubrication, Philosophical Transactions of the Royal Society of London. Series A, Mathematical and Physical Sciences, 266 (1970) 1–33.

R. Dama and L. Chang, An efficient and accurate calculation of traction in elastohydrodynamic contacts, Wear, 206 (1997) 113–121.

B. Jacod, C. H. Venner and P. M. Lugt, A generalized traction curve for EHL contacts, J. of Tribology-Transactions of the Asme, 123 (2001) 248–253.

H. Xu, A. Kahraman, N. E. Anderson and D. G. Maddock, Prediction of mechanical efficiency of parallel-axis gear pairs, J. of Mechanical Design, 129 (2007) 58–68.

Y. Diab, F. Ville and P. Velex, Prediction of power losses due to tooth friction in gears, Tribology Transactions, 49 (2006) 260–270, 2006/07/01.

J. Durand de Gevigney, F. Ville, C. Changenet and P. Velex, Tooth friction losses in internal gears: Analytical formulation and applications to planetary gears, Proceedings of the Institution of Mechanical Engineers, Part J: J. of Engineering Tribology, January 29 (2013).

P. Velex and F. Ville, An analytical approach to tooth friction losses in spur and helical gears-influence of profile modifications, J. of Mechanical Design, 131 (2009).

S. Li, A. Vaidyanathan, J. Harianto and A. Kahraman, Influence of design parameters on mechanical power losses of helical gear pairs, J. of Advanced Mechanical Design Systems and Manufacturing, 3 (2009) 146–158.

H. Liu, C. Zhu, Z. Sun and C. Song, Starved lubrication of a spur gear pair, Tribology International, 94 (2016) 52–60.

J. Durand de Gevigney, C. Changenet, F. Ville and P. Velex, Thermal modelling of a back-to-back gearbox test machine: Application to the FZG test rig, Proceedings of the Institution of Mechanical Engineers, Part J: J. of Engineering Tribology, January 16 (2012).

P. Yang and S. Wen, A generalized Reynolds equation for non-Newtonian thermal elastohydrodynamic lubrication, J. of Tribology, 112 (1990) 631–636.

H. Liu, Lubricated contact analysis of a spur gear pair with dynamic loads, Ph.D. Thesis, University of Warwick (2013).

H. Liu, K. Mao, C. Zhu and X. Xu, Mixed lubricated line contact analysis for spur gears using a deterministic model, J. of Tribology, 134 (2012) 021501–7.

H. Moes, Optimum similarity analysis with applications to elastohydrodynamic lubrication, Wear, 159 (1992) 57–66.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Associate Editor In-Ha Sung

Huaiju Liu, born in 1986, received the Ph.D. from the University of Warwick, UK in 2013. His research fields include tribology and dynamics of power transmissions.

Rights and permissions

About this article

Cite this article

Liu, H., Zhu, C., Sun, Z. et al. Coefficient of friction of a starved lubricated spur gear pair. J Mech Sci Technol 30, 2171–2177 (2016). https://doi.org/10.1007/s12206-016-0424-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-016-0424-y