Abstract

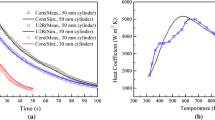

QFA (quench factor analysis) method is widely used to predict the mechanical properties such as hardness and strength according to temperature of quenched material that has to be determined by experimental heat treatment. But, QFA coupled with CFD (computational fluid dynamics) analysis of this study can predict the mechanical properties without the experiment of heat treatment except the experiment to determine the material constants of QFA. First of all, Jominy test and FPS (flexible polyhedron search) are performed to determine the material constants of QFA. The CFD analysis is applied to predict the cooling temperature of Al6061 cylinder cooled by water of 25°C during quenching of solid solution heat treatment. Hardnesses of T6 heat treated Al6061 cylinder is predicted by the QFA coupled with CFD analysis without experiment of heat treatment and then the predicted hardnesses are compared with experimentally measured hardnesses according to positions of cylinder. The predicted hardnesses of cylinder are in good agreement with the measured ones within a maximum error of 8.45%.

Similar content being viewed by others

References

D. H. Ko, T. J. Kim, H. J. Lim, J. M. Lee and B. M. Kim, FE-simulation and measurement of residual stress for Al6061-T6 heat treatment, Transaction of the KSME (A), 35(7) (2011) 717–722.

S. Esmaeili, D. J. Lloyd and W. J. Poole, Modeling of precipitation hardening for the naturally aged Al-Mg-Si-Cu Alloy AA6111, Acta Materialia, 51 (2003) 3467–3481.

M. B. Prime and M. R. Hill, Residual stress, stress relief and inhomogeneity in aluminum plate, Scripta Materialia, 46 (2002) 77–82.

H. S. Jang, The handbook of advanced aluminum technology, Hanlimwon (1997).

S. Liu, Q. Zhong, Y. Zhang, W. Liu, Xin ming and Y. Deng, Investigation of quench sensitivity of high strength Al-Zn-Mg-Cu Alloys by time-temperature-properties diagrams, Materials and Design, 31 (2010) 3116–3120.

G. P. Dolan and J. S. Robinson, Residual stress reduction in 7175-T73, 6061-T6 and 2017A-T4 Aluminum Alloys Using Quench Factor Analysis, Journal of Materials Processing Technology, 153–154 (2004) 346–351.

B. C. Shang, Z. M. Yin, G. Wang, B. Liu and Z. Q. Huang, Investigation of Quench Sensitivity and Transformation Kinetics during Isothermal Treatment in 6082 Aluminum Alloy, Materials and Design, 32 (2011) 3818–3822.

M. Tiryakioglu and R. T. Shuey, Modeling quench sensitivity of aluminum alloys for multiple tempers and properties: application to AA2024, Metallugical and Materials Transaction A, 41A (2010) 2984–2991.

W. L. Fink and L. A. Willey, Trans. Am. Inst. Min. Metall. Eng., 175 (1948) 414–427.

J. W. Evancho and J. T. Staley, Kinetics of precipitation in aluminum alloys during continuous cooling, Metallurgical Transactions, 5 (1974) 43–47.

G. P. Dolan, R. J. Flynn, D. A. Tanner and J. S. Robinson, Quench factor analysis of aluminum alloys using the jominy end quench technique, Materials Science and Technology, 21(6) (2005) 687–692.

D. A. Tanner and J. S. Robinson, Effect of precipitation during quenching on the mechanical properties of the aluminum Alloy 7010 in the W-temper, Journal of Materials Processing Technology, 153–154 (2004) 998–1004.

H. R. Shercliff and M. F. Ashby, A process model for age hardening of aluminum Alloys—II. applications of the model, Acta Metall. Mater., 38(10) (1990) 1803–1812.

ASTM A255-10, Standard test methods for determining hardenability of steel, ASTM Standards (1990).

D. M. Himmelblau, Applied nonlinear programming, McGaw-Hill (1972) 148–157.

C. E. Bates, G. E. Totten and L. M. Jarvis, Quench factor analysis: polymer vs. hot water, Ed. I. Tenaxol. (1994).

S. J. Hwang, D. H., Ko, D. H. Kim and B. M. Kim, Temperature prediction of Al6061 tube in cryogenic heat treatment by CFD analysis and experimental verification, Journal of the Korean for Precision Engineering, 28(10) (2011) 12010–1216.

Author information

Authors and Affiliations

Corresponding author

Additional information

Recommended by Editor Sung-Lim Ko

Dae-Hoon Ko is currently a Ph.D. candidate at the Precision Manufacturing Systems Division at Pusan National University in Busan, South Korea. His current research interests hot extrusion and heat treatment of aluminum alloys. Byung-Min Kim received his B.S., M.S. and Ph.D. degrees from Pusan National University, South Korea, in 1979, 1984 and 1987, respectively. He is currently a professor at the School of Mechanical Engineering at Pusan National University in Busan, Korea.

Rights and permissions

About this article

Cite this article

Ko, DH., Ko, DC., Lim, HJ. et al. Application of QFA coupled with CFD analysis to predict the hardness of T6 heat treated Al6061 cylinder. J Mech Sci Technol 27, 2839–2844 (2013). https://doi.org/10.1007/s12206-013-0732-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-013-0732-4