Abstract

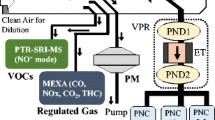

Particle size distribution and particle number concentration from diesel engines are subjects of significant environmental concerns especially in the EU. A few years ago, the UN-ECE PMP proposed a method for measuring particle emissions in the diluted exhaust of internal combustion engine vehicles, which has become a key method used in new dilution systems and sampling condition. This paper describes the effects of parameters such as condensation particle counter (CPC) according to test procedures, test fuel and vehicle test mode, including NEDC and CVS-75 mode. The main results obtained from this study can be summarized as follows: (1) Periodic calibration of the CPC system is essential because the long-term usage of a CPC leads to an underestimation in the measurements of small particles. (2) Particle emissions measured by the UN-ECE PMP method were found to exhibit comparable repeatability as compared to other regulated emissions. (3) In particle number concentration emitted from different-fueled vehicles, the sources of particle emissions in an ascending order of magnitude are as follows: DPF equipped diesel passenger vehicles, gasoline and LPG fueled vehicles, and DPF unequipped diesel passenger vehicles. Also, we found that the particle numbers of DPF equipped diesel passenger vehicles, gasoline and LPG-fueled vehicles can meet the EU regulation limit (<6.0×1011#/km), while DPF unequipped diesel passenger vehicles do not meet the EU limit.

Similar content being viewed by others

References

K. Donaldson, X. Y. Liu and W. MacNee, Ultrafine (Nanometer) particle mediated lung injury, Journal of Aerosol Science, 29 (1998) 553–560.

D. B. Kittelson and K. J. Baumgard, The influence of a ceramic particle trap on the size distribution of diesel particles, SAE paper No. 930733 (1993).

M. Kasper, U. Matter and H. Burtscher, NanoMet: On-line characterization of nanoparticle size and composition, SAE Paper No.2001-01-1998 (2001).

Programme on emissions of fine particles from passenger cars, ACEA Research Report (2002).

D. B. Kittelson, Diesel Aerosol Sampling in the Atmosphere, SAE Paper No. 2000-01-2212 (2000).

K. J. Baumgard, The effect of fuel sulfur and engine design on diesel exhaust particle size distributions, Ph.D Dissertation, Michigan Technological University (1995).

S. T. Bagley, K. J. Baumgard, L. D. Gratz, J. H. Johnson and D. G. Leddy, Characterization of fuel and aftertreatment device effects on diesel emissions, Research Report No.76. Health Effects Institute (1996).

I. S. Abdul-Khalek, D. B. Kittelson, B. R. Graskow and Q. Wei, Diesel Exhaust Particle Size: Measurement Issue and Trends, SAE Paper No. 980525 (1998).

I. S. Abdul-Khalek, D. B. Kittelson and F. Brear, Diesel Trap Performance: Particle Size Measurements and Trends, SAE paper No. 982599 (1998).

J. D. Anderson, UK Particle Measurement Programme Phase 2-Heavy Duty Methodology Development, Ricardo Consulting Engineers, Final Report DP03/21201 (2003).

J. D. Anderson, B. Giechaskiel, R. Munoz-Bueno and E. Sandbach, Particle Measurement Program (PMP) Light-duty Inter-laboratory Correlation Exercise (ILCE_LD), Document No. GRPE-54-08-Rev.1, European Commission Joint Research Centre (2007).

Regulation 83: Vehicle Emissions Legislation; Light-duty Vehicles and PCVs, European Commission Joint Research Centre.

T. Lim, H. Kim, H. Cho, J. Lee, Y. Jeong and H. Jeon, An Experimental Study of Dilution Methods for Preventing Volatile Particle Generation during Measurement of Diesel Particle Number Concentration, Transactions of KSAE, 17(5) (2009) 67–73.

J. Lee, H. Kim, G. Cho and Y. Jeong, Analysis of Diesel Nano-particle number distribution characteristics for three different particle measurement systems, Transactions of KSAE, 15(6) (2007) 144–150.

K. C. Johnson, T. D. Durbin, H. Jung, A. Chaudhary, D. R. Cocker, J. D. Herner, W. H. Robertson, T. Huai, A. Ayala and D. B. Kittelson, Evaluation of the european PMP methodologies during on-road and chassis dynamometer testing for DPF equipped heavy-duty diesel vehicles, Aerosol Science and Technology, 43 (2009) 962–969.

R. Payri, S. Molina, F. J. Salvador and J. Gimeno, A study of the relation between nozzle geometry, Internal Flow and Sprays Characteristics in Diesel fuel Injection Systems, Journal of Mechanical Science and Technology, 18(7) (2004) 1222–1235.

L. Wei, L. O. Brian, F. B. Oliver and J. S. Gilmore, Calibration of condensation particle counters, SAE Paper 2005-01-0189 (2005).

J. K. Agarwal and G. J. Sem, Generating submicron monodisperse aerosols for instrument calibrations, TSI Quarterly, May/June, p5, TSI Incorporated, Shoreview, MN, USA (1978).

F. Bischof and H. -G. Horn, Two On-line measuring techniques for the physical characterization of ultrafine particles in vehicle exhaust from diesel and other engines, MTZ Motorentechnische Zeitschrift 60(4) (1999).

R. Caldow, M. R. Palmer and F. R. Quant, Performance of the TSI Model 3010 Condensation Particle Counter, Proceedings of AAAR Annual Meeting, October 12–16, San Francisco, CA, USA (1992).

R. Sierens, An experimental and theoretical study of liquid LPG injection, SAE Paper No. 922363 (1992).

E. J. Lee, J. W. Park, K. Y. Huh, J. J. Choi and S. D. Bae, Simulation of fuel/air mixture formation for heavy duty liquid phase LPG injection engines, SAE Paper No. 2003-01-0636 (2003).

Boretti, Development of a direct injection high efficiency liquid phase LPG spark ignition engine, SAE Paper No. 2009-01-1881 (2009).

N. Mizushima, S. Sato, T. Yamamoto, G. Konagai, Y. Ogawa, U. Sawut, K. Kawayoko and B. Takigawa, Combustion characteristics and performance increase of an LPG-SI engine with liquid fuel injection system, SAE of Japan Paper No. 20093890 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was recommended for publication in revised form by Associate Editor Kyoung Doug Min

Hongsuk Kim received his Ph.D in Mechanical Engineering, Sungkyunkwan University, Korea. He is currently a senior researcher at Green Engine Research Team of Korea Institute of Machinery and Materials. His research interests are after-treatment technology of diesel & gasoline engines and emission measurement technology.

Jinwook Lee received his Ph.D in Mechanical Engineering, Seoul National University, Korea. He is currently an assistant professor at Department of Mechanical Engineering of Soongsil University. His research interests are clean powertrain and low-carbon fuel system technology.

Rights and permissions

About this article

Cite this article

Kim, H., Lee, J. Quantitative analysis of vehicle particle emission by using calibrated CPC system. J Mech Sci Technol 25, 2959–2967 (2011). https://doi.org/10.1007/s12206-011-0815-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12206-011-0815-z