Abstract

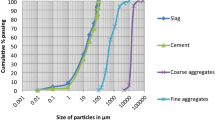

This paper investigates the effects of using Ground Granulated Blast Furnace Slag (GGBFS), Lead Slag (LS) and Zinc Slag (ZS) as replacement for sand on the strength of concrete. Compressive strength, flexural strength, water absorption and density were tested at 14, 28 and 56 days. In this study, a total of 40 concrete samples, including Pozzolanic Portland Cement (PPC), GGBFS, LS and ZS concretes, were produced with a water-to-cement ratio of 0.4, cement content of 400 kg/m3 and slag/sand replacement ratio of 30%. A superplasticizer was used in concrete at a proportion of 1.5% per weight of cement. The results show that the type of slag affects the mechanical properties of concrete. Compressive strength increased when GGBFS was used but decreased or remained unchanged when ZS or LS, respectively, were used as sand replacements in concrete. The results also demonstrated that the flexural strength of control concrete was higher than that of other mixtures. Dry density increased and water absorption decreased with the use of slags in concrete. In general, it can be concluded that the use of GGBFS and lead slag as fine aggregates in concrete is technically possible and useful in some cases, whereas the use of zinc slag has a negative effect on concrete.

Similar content being viewed by others

References

ACI 304.3 (1994). Heavy weight concrete: Measuring, mixing, transporting and placing, Manual of Concrete Practice, American Concrete Institute

Al-Jabri, K. S., Hisada, M., Al-Saidy, A. H., and Al-Oraimi, S. K (2009). “Performance of high strength concrete made with copper slag as a fine aggregate.” Construction & Build Materials, Vol. 23, pp. 2132–2140

ASTM C138/C138M-01a (2001). Standard test method for density (unit weight), yield and air content (Gravimetric) of concrete, Annual Book of ASTM Standards

ASTM C29/C29M-97 (2003). Standard test method for bulk density (unit weigth) and voids in aggregate, West Conshohocken

ASTM C33 (2003). Standard specifications for concrete aggregates, Annual Book of ASTM Standards

ASTM C642 (2005). Standard test method for density, absorption and voids in hardened concrete, West Conshohocken

ASTM C78-94 (1994). Standard test method for flexural strength of concrete (using simple beam with third-point loading), West Conshohocken

ASTM C989 (1994). Standard specification for ground granulated blast furnace slag for use in concrete and mortars, Annual Book of ASTM Standards

Barna, R., Moszkowicz, P., and Gervais, C. (2004). “Leaching assessment of road materials containing primary lead and zinc slags.” Waste Management, Vol. 24, pp. 945–955

BS 1881-Part 116 (1998). Testing concrete: Method for determination of compressive strength of concrete cubes, British Standard Institution

BS 882 (1992). Specification for aggregates from natural sources for concrete, British Standards Institution, London, U.K

Chidiac, S. E. and Panser, D. K. (2008). “Evolution of mechanical properties of concrete containing ground granulated blast furnace slag and effects on the scaling resistance test at 28 days.” Cement & Concrete Res., Vol. 30, pp. 63–71

Gesoğlu, M., Güneyisi, E., and Özbay, E. (2009). “Properties of self-compacting concretes made with binary, ternary, and quaternary cementitious blends of fly ash, blast furnace slag, and silica fume.” Construction & Build Materials, Vol. 23, No. 9, pp.1847–1854

Morrison, C., Hooper, R., and Lordner, K. (2003). “The use of ferrosilicate slag from ISF zinc production as a sand replacement in concrete.” Cement & Concrete Res., Vol. 33, No. 3, pp. 2085–2089

Neville, A. and Brooks, J. (2002). Concrete technology, Longman, U.K

Neville, A. M. (1996). Properties of concrete, Longman Group UK Limited Press, London

Penpolcharoen, M. (2005). “Utilization of secondary lead slag as construction material.” Cement & Concrete Res., Vol. 35, pp. 1050–1055

Qasrawi, H., Shalabi, F., and Asi, I. (2009). “Use of low Cao unprocessed steel slag in concrete as fine aggregate.” Construction & Build Material, Vol. 23, pp. 1118–1125

Weeks, C., Hand, R. J., and Sharp, J. H. (2008). “Retardation of cement hydration caused by heavy metals present in ISF slag used as aggregate.” Cement & Concrete Composites, Vol. 30, No. 7, pp 970–978

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mosavinezhad, S.H.G., Nabavi, S.E. Effect of 30% Ground Granulated Blast Furnace, Lead and Zinc Slags as sand replacements on the strength of concrete. KSCE J Civ Eng 16, 989–993 (2012). https://doi.org/10.1007/s12205-012-1240-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12205-012-1240-2