Abstract

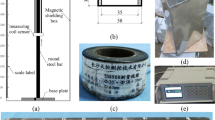

In this study, magnetomechanical coupling tests were performed on Q235 solid round steel model specimens in NIM-200HF magnetomechanical coupling equipment. Hysteresis loops were obtained in different magnetic fields and stresses. Magnetization curves were also achieved at different stresses. Influence of the applied stresses on the hysteresis loops was investigated. The stress sensitive region and linear stress sensitive region of magnetic induction were determined for the model specimen according to the experimental data. The dependence relation of magnetic induction versus applied stresses was established, and the optimum magnetic field was determined in the stress sensitive range of magnetic induction, which builds a basis for nondestructive testing (NDT) of stress with the total magnetic flux for steel structure. Based on modified Jiles-Atherton’s model of magnetic hysteresis, the hysteresis loop for Q235 steel 4-mm diameter model specimen was numerically simulated, which was well consistent with the experimental results.

Similar content being viewed by others

References

Takahashi S, Echigoya J, Motoki Z. Magnetization curves of plastically deformed Fe metals and alloys [J]. Journal of Applied Physics, 2000, 87(2): 805–813.

Liu T, Kikuchi H, Kamada Y, et al. Comprehensive analysis of Barkhausen noise properties in the cold rolled mild steel [J]. Journal of Magnetism and Magnetic Materials, 2007, 310(2): 989–991.

Yelbay H I, Cam I, Gür C H. Non-destructive determination of residual stress state in steel weldments by Magnetic Barkhausen Noise technique [J]. NDT & E International, 2010, 43(1): 29–33.

Pérez-Benitez J A, Capó-Sánchez J, Padovese L R. Characterization of angular dependence of macroscopic magnetic properties in ASTM 36 steel using magnetic Barkhausen noise [J]. NDT & E International, 2007, 40(4): 284–288.

Capó-Sánchez J, Pérez-Benitez J, Padovese L R. Analysis of the stress dependent magnetic easy axis in ASTM 36 steel by the magnetic Barkhausen noise [J]. NDT & E International, 2007, 40(2): 168–172.

Zurek Z H. Magnetic contactless detection of stress distribution and assembly defects in constructional steel element [J]. NDT & E International, 2005, 38(7): 589–595.

Krause T W, Pattantyus A, Atherton D L. Investigation of strain dependent magnetic Barkhausen noise in steel [J]. IEEE Transactions on Magnetics, 1995, 31(6): 3376–3378.

Gatelier-Rothea C, Chicois J, Fougeres R, et al. Characterization of pure iron and (130 ppm) carboniron binary alloy by Barkhausen noise measurements: Study of the influence of stress and microstructure [J]. Acta Materialia, 1998, 46(14): 4873–4882.

Liu T, Kikuchi H, Ara K, et al. Magnetomechanical effect of low carbon steel studied by two kinds of magnetic minor hysteresis loops [J]. NDT & E International, 2006, 39(5): 408–413.

Ktena A, Hristoforou E. Stress dependent magnetization and vector preisach modeling in low carbon steels [J]. IEEE Transactions on Magnetics, 2012, 48(4): 1433–1436.

Vertesy G, Uchimoto T, Tomáš I, et al. Nondestructive characterization of ductile cast iron by magnetic adaptive testing [J]. Journal of Magnetism and Magnetic Materials, 2010, 322(20): 3117–3121.

Takahashi S, Kobayashi S, Kamada Y, et al. Similarity rules of magnetic minor hysteresis loops in Fe and Ni metals [J]. Journal of Magnetism and Magnetic Materials, 2008, 320(15): 2056–2061.

Motoasca S, Nicolaide A, Helerea E, et al. Analytical method for hysteresis modelling of soft magnetic materials [C]//Proceedings of the 12th International Conference on Optimization of Electrical and Electronic Equipment. Romania, Brasov: Transilvania University Press, 2010: 168–173.

Jiang Shou-ting, Li Wei. Magnetic physics of condensed matter [M]. Beijing: Science Press, 2003 (in Chinese).

Zhu B, Lo C C H, Lee S J, et al. Micromagnetic modeling of the effects of stress on magnetic properties [J]. Journal of Applied Physics, 2001, 89(11): 7009–7011.

Fang D N, Feng X, Hwang K C. Study of magnetomechanical non-linear deformation of ferromag-netic materials: Theory and experiment [J]. Proceedings of the Institution of Mechanical Engineers. Part C: Journal of Mechanical Engineering Science, 2004, 218(12): 1405–1410.

Ercuta A, Mihalca I. Magnetomechanical damping and magnetoelastic hysteresis in permalloy [J]. Journal of Physics D: Applied Physics, 2002, 35(22): 2902–2908.

Xiong Er-gang. Theoretical and experimental research on total magnetic flux stress testing technique for steel structure based on the magnetomechanical effect [D]. Xi’an: Xi’an University of Architecture and Technology, 2007 (in Chinese).

Hauser H, Melikhov Y, Jiles D C. Examination of the equivalence of ferromagnetic hysteresis models describing the dependence of magnetization on magnetic field and stress [J]. IEEE Transactions on Magnetics, 2009, 45(4): 1940–1949.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: the National Natural Science Foundation of China (Nos. 51108035, 51178388 and 10972168), the Natural Science Basic Research Plan in Shaanxi Province of China (No. 2010JQ7006), the China Postdoctoral Science Foundation (No. 20100481313) and the Special Fund for Basic Scientific Research of Central College of China (No. CHD2012ZD012)

Rights and permissions

About this article

Cite this article

Xiong, Eg., Wang, Sl. & Miao, Xy. Research on magnetomechanical coupling effect of Q235 steel member specimens. J. Shanghai Jiaotong Univ. (Sci.) 17, 605–612 (2012). https://doi.org/10.1007/s12204-012-1332-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12204-012-1332-7

Key words

- magnetomechanical coupling tests

- magnetic hysteresis loops

- stress sensitive region

- magnetic induction

- total magnetic flux

- nondestructive testing (NDT)

- magnetic hysteretic model