Abstract

We propose a procedure for the determination of tin in tomatoes after wet digestion of the samples in HNO3 using hydride generation inductively coupled plasma optical emission spectrometry. The effect of acidity from HCl and HNO3 (0.01–4.0 mol L-1) as well as the presence of l-cysteine on the efficiency of SnH4 generation by reaction with the NaBH4 reductant was investigated. Optimal conditions were evaluated in terms of precision, accuracy (by recovery test) and limit of detection. The best results were obtained with l-cysteine and nitric acid for sample acidificitation. Addition of 1 % (m/v) l-cysteine enhanced the Sn signal and expanded the optimal range of HNO3 concentrations towards higher values; hence, strict control of the acidity could be avoided, up to 1.0 mol L-1. Under the optimized conditions, a detection limit of 1.2 ng mL-1 was achieved. The applicability of the proposed method was demonstrated by the determination of low tin contents in digests of fresh and canned tomato samples with satisfactory results.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Canning is a simple technology for preservation of fresh fruits and vegetables to avoid spoilage, and tinplate coated on both sides with pure tin has been widely used in the food industry for the production of food cans. It may result, however, in some tin dissolving into the food content, especially when plain uncoated internal surfaces are used, due to corrosion and leaching of tin from unlacquered cans. A concise review devoted to canned food, factors affecting the rate of dissolution of tin and the acute toxicity of tin was recently presented by Blunden and Wallace (Blunden and Wallace 2003).

The determination of tin in canned food has become very important in terms of its safety and in assessing quality. Spectrophotometric (Gutiérrez et al. 1985; Huang et al. 1997) or fluorimetric (Morte et al. 2009; Manzoori et al. 2006) methods are most often employed. Atomic spectrometric techniques based on pneumatic nebulization sample introduction have also been proposed for this purpose, namely, flame atomic absorption (Munteanu et al. 2010; Knápek et al. 2009; Rafique et al. 2009), inductively coupled plasma optical emission spectrometry (ICP OES) (Boutakhrit et al. 2011; Morte et al. 2012) or inductively coupled plasma mass spectrometry (ICP MS) (Trandafir et al. 2012). Although canned food may contain a higher tin content (especially foods from unlacquered cans) and can be determined by normal sample introduction, its concentration in fresh food is significantly lower, limiting the use of spectrometric methods due to insufficient sensitivity and limits of detection. The exception is ICP MS, which ranks as one of the most sensitive methods for determining tin at the parts-per-trillion level (Boutakhrit et al. 2011; Trandafir et al. 2012).

In general, a pre-concentration step is advisable, and hydride generation (HG) coupled with spectrometry is the best way to introduce samples, permitting direct quantitative determination of trace amounts of tin. Reduction of hydride-forming elements (e.g. As, Bi, Sb, Se and Sn) to volatile hydrides in acid media by sodium tetrahydroborate NaBH4 (THB) increases the detection performance of conventional nebulization methods remarkably (two to three orders of magnitude) (Pohl 2004). For the determination of tin, however, hydride generation is not an easy task since there are difficulties in evaluating the optimal experimental conditions. In light of recent studies, parameters including the reductant–acid combination (especially the type of acid and its concentration (Farías et al. 2002; Feng et al. 1997; Chen et al. 1996; Matusiewicz and Krawczyk 2010; Qiu et al. 1990) and THB concentration (Farías et al. 2002; Feng et al. 1997; Chen et al. 1996; Matusiewicz and Krawczyk 2010)) were found to influence the efficiency of the reduction process. In most cases, it was observed that tin hydride could be effectively generated only in a low, narrow acidity range, i.e. 0.1–0.3 mol L-1 of HCl, HNO3 or H2SO4 (Farías et al. 2002; Feng et al. 1997; Chen et al. 1996; Matusiewicz and Krawczyk 2010; Qiu et al. 1990). Moreover, strict control of the acid concentration is required because small changes near the maximum may lead to significant reductions in sensitivity (Farías et al. 2002; Feng et al. 1997; Chen et al. 1996; Qiu et al. 1990). It may be troublesome, especially for solid samples, required to be digested before detection by the aforementioned atomic spectrometry methods and where the final acid concentration is typically higher than 0.1 mol L-1. The use of l-cysteine has been suggested to expand the optimum range of acidity towards higher values (Chen et al. 1996; Pitzalis et al. 2009). Such an effect in the case of tin was recently discussed by Pitzalis et al. (2009) for a THB + HNO3 mixture.

Very little information regarding determinations of tin in canned food by hydride generation in conjunction with ICP OES has been published. So far, only one study (Rončević et al. 2012) has reported investigation of the best measurement conditions appropriate for determination of tin in a low concentration range in canned fruits and vegetables. Selected tin emission lines were measured in prepared samples by means of HCl treatment and addition of tartaric acid, followed by hydride generation with THB solution.

The present studies were undertaken to evaluate an accurate procedure for the determination of tin in a low concentration range in fresh and canned vegetables (tomatoes) by means of hydride generation inductively coupled plasma optical emission spectrometry (HG ICP OES) after wet digestion of the samples in HNO3. The effect of the type of can as well as the storage time in the open can on the tin content in the analysed samples was also studied. A hydride generation method from Sn(IV) was optimized, taking into account its application to measurements of tin in digests of real samples.

Experiment

Samples

Three samples of fresh and six samples of canned peeled tomatoes were purchased in local markets (Wroclaw, Poland). The latter were of different brands (imported) and differed in the internal coating of the can. Two lacquered and four unlacquered cans were examined. Canned tomato samples were analysed immediately after opening, and in the case of unlacquered cans, additional analyses were performed 24 and 48 h after the cans were first opened. The opened cans were stored in the refrigerator.

Reagents

All of the chemicals were of analytical grade. A commercial 1,000 μg mL-1 ICP standard stock solution of Sn(IV) was used (Merck, Darmstadt, Germany). Working solutions (up to 5 μg mL-1 for calibration curves and 1 μg mL-1 for optimization investigations) were prepared daily by dilutions of the concentrated standard and acidification with 0.1 mol L-1 HCl or HNO3. Solutions of hydrochloric and nitric acids were prepared from concentrated HCl and HNO3 (Merck). Reducing agent solutions of NaBH4 (THB), C(CH3)3NH2-BH3 (TBAB) and (CH3)2NH-BH3 (DMAB) were freshly prepared by dissolving appropriate amounts of their powders (Sigma-Aldrich, Germany) in a 0.1-mol L-1 solution of NaOH (POCh) and filtering before measurements to eliminate turbidity. l-Cysteine (Sigma) was used as a solid reagent. For sample digestion, 65 % (v/v) HNO3 (Merck) was used. Deionized water (18.3 MΏ cm-1) from EASYpure (Barnstead, Model D7033) was used in all experiments. Glassware and all vessels were cleaned with 10 % nitric acid and rinsed several times with deionized water.

Sample Preparation

Before sample treatment, tomatoes were chopped and pounded to a paste with a mortar and pestle. A wet acid digestion procedure by hot-plate heating was applied prior to measuring tin in all of the tomato samples. In the procedure, 3 g of (wet) tomato sample was weighed into a 150-mL beaker, and 10 mL of concentrated HNO3 was added. The beaker was covered with a watch glass and left to pre-digest overnight. After this time, the sample solution was gently heated on a hot plate until all fumes of NO x ceased. Then, the sample solution was reduced to less than 1 mL (to assure a final acidity of ~0.5 mol L-1 HNO3), cooled and quantitatively transferred into a 25-mL volumetric flask. The resulting sample solution was pre-treated with the addition of solid l-cysteine (to a final 1 % (m/v) concentration) and made up to volume with deionized water. The mixture was left for 20 min before HG measurements. Three parallel samples were prepared for every analysis. With each set of digested samples, a blank was prepared in the same way to make correction of the final analytical signals. To avoid differences in acid concentration between the samples and standard solutions, the working standard solutions were also processed through the entire preparation procedure.

Hydride Generation

Optimization Studies

Tin hydrides were generated in a continuous flow system with a gas–liquid phase separation coupled to the ICP OES spectrometer. The system consisted of a modified cyclonic spray chamber, a parallel pneumatic nebulizer (Burgener) and peristaltic pumps with delivery tubes (Welna et al. 2011). The chamber was connected directly to a plasma torch. Sample and acid were simultaneously pumped in two separate streams to the first Y-junction and then mixed with reductant solution in the second Y-junction. Then, the reaction mixture was introduced at the bottom of the chamber through a 60-mm-long tube (0.5 mm i.d.). Tin hydride and other gaseous co-products were swept by a carrier Ar stream, introduced through the nebulizer gas inlet, and transported into the plasma. The sample inlet of the nebulizer was clogged. The wastes were drained with the aid of a peristaltic pump. To achieve stability, the level of post-reaction liquid in the chamber was controlled and kept at a constant level. The same chamber and nebulizer were also used to nebulize the sample solution.

HG ICP OES Analysis

Using the same system, for the samples after wet digestion, tin hydride was generated directly from the acidified solutions containing 1 % (m/v) l-cysteine by merging them with THB solution in the single Y-junction.

Apparatus

Measurements were performed using a Jobin Yvon sequential inductively coupled plasma emission spectrometer (JY 38S). The working parameters for HG and ICP OES detection are listed in Table 1. After the reaction mixture passed into the chamber, 30 s was necessary to achieve steady Sn signals.

Results and Discussion

Parameters affecting Sn hydride generation from Sn(IV) were optimized, including reductant–acid conditions and the presence of l-cysteine. Next, the proposed method was utilized for determination of tin in real samples.

Optimization of Tin Hydride Generation Procedure

All of the intensities of Sn measured here were background corrected and expressed as net intensities calculated as the difference between the measured intensities for the analyte and the background. The mean values were obtained from three repeated measurements with relative standard deviations (RSDs) ranging from 1 to 10 %, depending on the experimental conditions.

Emission Line Selection

Four emission lines of Sn, i.e. 189.9, 235.5, 242.9 and 283.9, were tested under hydride generation conditions based on their line intensities and the signal-to-background ratio (I Sn/I b). The 283.9-nm line was chosen because it gave the best results (being the least noisy with the best sensitivity).

Effect of Reducing Agent Type and Concentration

The effects of three borane reducing agents, i.e. THB, TBAB and DMAB, on the Sn signal were examined in the reaction with HCl. A concentration of 0.2 mol L-1 of reductant was chosen for the investigations because it corresponded to the highest solubility for the least soluble agent, TBAB. Generally, the efficiency decreased in the following order: THB>TBAB>>DMAB. The results for TBAB were nearly twofold lower than those obtained with THB. Reduction of Sn with DMAB was not efficient in practise. Therefore, THB was found to be the most favourable medium.

In the next step, the influence of THB concentration was examined. Solutions of THB in the range of 0.1–1.5 % (m/v) applying 0.2 mol L-1 HCl were considered, as THB–HCl is the typical reducing condition in the HG process. The results are given in Fig. 1. It was observed that the tin signal increased up to 1.0 % (m/v) THB. Above this concentration, Sn emission was nearly constant. In addition, concentrations of THB higher than 1.0 % (m/v) made the plasma unstable, probably due to the excessively large amount of hydrogen produced from the reaction of THB with acid.

In summary, 1.0 % (m/v) THB was observed to be optimal for generation of Sn hydride.

The effect of the NaOH concentration used to stabilize the THB was also studied. Five 1 % (m/v) THB solutions in 0.01, 0.05, 0.1, 0.25 and 0.5 mol L-1 NaOH were prepared. The investigation was conducted at a fixed concentration of HCl (0.2 mol L-1). It was found that the intensity of tin increased slightly with NaOH concentration up to 0.1 mol L-1, with no significant further variation observed between 0.1 and 0.5 mol L-1 NaOH (there were differences in the SD uncertainty). Since tin generation is greatly dependent on the pH of the reaction mixture and larger amounts of NaOH made the plasma unstable as well as increasing the reagent blank, 0.1 mol L-1 NaOH was finally chosen.

Effect of Acids and Acidity Condition

The effects of the two inorganic acids, i.e. HCl and HNO3, on the Sn response were studied over a concentration range of 0.01 to 4.0 mol L-1. An optimal THB concentration was used. The results of Sn signal variation versus concentration of acid are shown in Fig. 2.

A rapid growth in the Sn signal was observed up to ~0.3 mol L-1 HCl and HNO3, which corresponded to the so-called critical value (CV) where the sum of THB+NaOH is stoichiometrically equal to the amount of acid and the maximum analyte signal is expected to be achieved (Qiu et al. 1990). Past the CV point, at 0.26 mol L-1 (HCl, HNO3), the Sn signal began to decrease systematically, reaching a nearly negligible value for HCl and HNO3 concentrations >2.0 mol L-1; the effect was more pronounced for HCl. In the acidity range from 0.4 to 1.0 mol L-1, the responses of Sn were 15–30 % lower in HCl than in HNO3.

The acidity curves in HCl and HNO3 were very close, giving sharp maximums at the CV point. Additionally, the maximum Sn responses were practically identical, independent of the acid used. Both were found to be appropriate for effective SnH4 generation, which, in the case of HNO3, is quite different from results previously reported (Farías et al. 2002; Chen et al. 1996; Matusiewicz and Krawczyk 2010).

As it can be seen in Fig. 2, when using strong inorganic acids, the generation of SnH4 is pH dependent, and it took place only in a narrow, low acidity range. Accordingly, the pH values of the reaction mixtures in the wastes leaving the chamber were measured and plotted against the Sn responses. It was observed that efficient reduction of Sn(IV) in its reaction with HCl or HNO3 and THB could be achieved between pH 1.5 and 8.5.

Effect of Mixing Sequence of Reagents

In all of the former experiments, SnH4 was generated using a typical setup (S1), where the analyte (Sn(IV)) was merged with acid in the first Y-junction and then with THB solution in the second Y-junction. To evaluate the influence of mixing sequence of HG reagents on the efficiency of SnH4 formation, the following setups were tested:

-

(S1)

Sn(IV)+acid // THB

-

(S2)

Sn(IV)+THB // acid

-

(S3)

THB+acid // Sn(IV)

-

(S4)

Sn(IV)+acid+THB

In sequence 2 (S2), the analyte was first mixed with THB, and the addition of acid was delayed. In the third sequence (S3), THB was allowed to react with acid before merging with the analyte. In the fourth setup (S4), all of the reagents were merged simultaneously in a single cross-shaped junction. The HG reagents used for the experiments were 1 μg mL-1 Sn(IV) (in 0.1 mol L-1 HCl or HNO3), 1 % (m/v) THB, 0.01–4.0 mol L-1 HCl and HNO3. The Sn signal measured with S1 under optimal conditions of 0.25 mol L-1 HCl or HNO3 and 1 % (m/v) THB was taken as a reference.

When the Sn(IV) and THB solutions were merged (S2), SnH4 could be effectively generated over a wide range of acidity. The effect of HCl or HNO3 around the CV point (S1) was not observed in practise, even at elevated acidity. The Sn intensity reached was comparable to the reference Sn signal. Such behaviour can be attributed to the composition of the reaction mixture, favourable for SnH4 formation (Pitzalis et al. 2009).

The addition of Sn(IV) to the THB+acid mixture (S3) reduced Sn emissions by 23 and 33 % with HNO3 and HCl, respectively. A similar effect, previously ascribed to the reaction environment, was also observed by Pitzaliz et al. (2009). Moreover, generation of Sn hydride could only be observed at an acid concentration <0.5 mol L-1 since, at higher acidities, the experimental setup was frequently disconnected due to greater production of H2 from the reaction between THB and acid in the Y-junction. The repeatability of the measurements was also poor. The same was observed with S2. The solution of analyte was acidified (0.1 mol L-1), leading to subsequent decomposition of the THB when merged in the Y-junction. As a consequence, unless generation of SnH4 was possible over a wider range of acid concentrations, the precision of the measurements was much worse in comparison to those under S1 conditions (RSDs > 10 %).

In the case of simultaneous mixing of all reagents (S4), the dependencies of the Sn signal upon the acids were comparable to those with S1; however, the intensities were 18–29 % lower. These differences could be attributed to a too short contact time between the reagents.

Considering both the efficiency and stability of the measurements, the first mixing sequence (S1) was employed here as optimal.

Effect of l-Cysteine

The effect of l-cysteine on the Sn signal was studied over a concentration range of 0.1 to 2.0 % (m/v). l-Cysteine was added to the 1.0 μg mL-1 Sn(IV) solution and left to equilibrate for 20 min. An optimal experimental setup (S1), THB and acid (HCl, HNO3) concentrations were used. It was observed that the intensity of the tin signal was relatively constant over the 0.5–2.0 % (m/v) range; therefore, 1 % (m/v) of l-cysteine was chosen for this work.

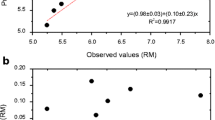

Next, the effect of acid concentration on SnH4 generation in the presence and absence of 1 % (m/v) l-cysteine was compared. The experiments were conducted at a fixed THB concentration, and the acidity from HCl and HNO3 varied between 0.01 and 2.0 mol L-1. The acidity curves are given in Fig. 3.

It can be seen that addition of l-cysteine extended the Sn signal at higher acidities, giving the maximum value over a range of acid concentrations from 0.05 to 1.0 mol L-1 HNO3 (Fig. 3a) and from 0.1 to 0.5 mol L-1 HCl (Fig. 3b). Moreover, the maximum Sn signals were about 48 % (HNO3) and 40 % (HCl) greater than those obtained under optimal acid conditions (0.25 mol L-1) in the absence of l-cysteine. Our results support the positive role played by l-cysteine in the HG process from Sn(IV) in acidic media (Chen et al. 1996; Pitzalis et al. 2009). Further increases in acid concentrations, however, caused a continuous decrease in the Sn signal; the response obtained in 2 mol L-1 HNO3 or 1 mol L-1 HCl was comparable to the reference signal measured without l-cysteine at low acidity.

Because HNO3 gave a plateau for Sn emission at concentrations up to 1 mol L-1 and is commonly used for sample digestion, it was selected to be the most appropriate reaction medium for Sn determination in real samples. Thus, the efficiency of Sn generation in the reaction of a sample solution acidified with 0.5 or 1.0 mol L-1 HNO3 in the presence and absence of l-cysteine was checked. In this approach (S5), the mixture was directly merged with the THB solution. It was observed that, independent of the acid concentration, the Sn signals were closely similar and comparable to those obtained when the acid solution was injected as a separate stream (S1).

In summary, for tin determination in tomatoes by HG ICP OES, samples were made up in ~0.5 mol L-1 HNO3 and 1 % (m/v) l-cysteine, and 1 % (m/v) THB was used as the reductant.

Analytical Performance

The analytical performance of the optimized HG conditions for tin determination was characterized by means of limit of detection (LOD), linear dynamic range, linearity coefficient (R 2), slope of calibration (a) and precision of replicate (n = 3) measurements of the Sn signal (expressed by RSD). The LOD, RSD and R 2 values as well as the slope coefficients obtained with 0.25 and 0.5 mol L-1 HNO3 are listed in Table 2. Some results achieved with pneumatic nebulization (PN) are also included.

In all cases, the Sn signal was linear up to 5 μg mL-1, and the linearities were very good (R 2 ranged from 0.9955 to 0.9993). The detection limits for Sn(IV), defined as three times the standard deviation of the blank (3σ criterion) using HNO3 only, were similar (variations were within 20 %) and about two times higher than this obtained in the presence of l-cysteine. As shown in Table 2, the lowest LOD was found for the condition with l-cysteine. This value was about two orders of magnitude lower than that estimated for PN, and the sensitivity enhancement compared to ICP OES was 45-fold.

It can be seen that, using the HG method, the LOD for tin was significantly reduced (two orders of magnitude). The RSD values for HG from Sn(IV) were lower than those observed when applying PN to measure Sn by ICP OES. Precisions using the HG technique based on the procedure without l-cysteine were similar. As for LOD, the best precision for the HG process from Sn(IV) was obtained using l-cysteine.

Application to Real Samples—Analysis of Fresh and Canned Tomato Samples

Because a certified reference material regarding tin content in expected concentration range was not available to us, the accuracy of the optimized HG ICP OES method for tin determination in food samples was evaluated through the recovery test based on measurements of spiked tomato samples with standard tin solutions at different concentrations (0.2, 0.5 and 1.0 μg mL-1). The experiments were performed in triplicate. It was observed that, independent of the spike level, acceptable recoveries were obtained, ranging between 92.9 and 109 %, whereas the RSDs were within 5 %.

The results for total concentrations of tin (the mean values of three replicates with standard deviations (SDs)) in examined tomato samples are presented in Table 3. They are expressed in micrograms per gram of wet weight (w.w.). For canned tomatoes, samples were analysed immediately after opening the cans. The precision of the measurements ranged from 3.6 to 12 %.

The concentration of Sn in analysed tomato samples ranged from undetectable to 5.67 μg g-1 wet weight and was below the imposed limit of 200 mg/kg established by the Commission of the European Communities (Commission Regulation (EC) No 1881). In general, the canned tomatoes contained greater amounts of Sn than the fresh samples, and the effect was dependent on the internal coating of the can. The Sn concentration in tomatoes from lacquered cans was significantly lower, about 13-fold on average, than those in samples from unlacquered ones. This confirmed the statement that enriched concentrations of tin in canned food are mostly caused by corrosion and leaching of tin from unlacquered cans (Knápek et al. 2009; Rafique et al. 2009; Trandafir et al. 2012; Rončević et al. 2012). The results also showed that lacquer inside the cans can keep Sn levels in canned tomatoes at the level observed in fresh samples.

Considering the analytical performance of both ICP OES and HG ICP OES, the results obtained here demonstrated that conventional sample introduction (without the hydride system) was not appropriate, especially for analysis of fresh tomato samples and tomatoes from completely lacquered cans (no. 1–5) due to limitations in the capability of ICP OES at such low concentrations of tin.

The effect of time on the Sn concentration in tomatoes stored in opened cans without lacquer was also checked, and the results (average values) are detailed in Table 4.

As can be seen, the total content of tin in tomatoes was considerably affected by the time of storage in open unlacquered cans due to corrosion of the container. Most important was the time point 24 h after opening, when up to twice as much tin was detected. With longer periods of time, no additional tin was accumulated, indicating that the increased leaching of tin from unlacquered cans reached a maximum during the first day after initial opening of the can.

Conclusion

The efficiency of tin hydride generation from Sn(IV) was found to be strongly dependent on the reducing conditions. The acid concentration was the critical factor affecting SnH4 formation. Typically, it could only be generated in a low, narrow acidity range of HCl and HNO3. In the presence of 1 % (m/v) l-cysteine, generation of SnH4 seemed to be less dependent on acid concentration, and the need for strict control of acidity could be avoided to some extent, especially in the case of HNO3, as a relatively wide acid concentration range for maximum SnH4 generation was achieved. Simultaneously with shifting the tin hydride generation to elevated acidities, the addition of l-cysteine enabled us to generate Sn hydride with higher effectiveness (by nearly 50 %).

The optimal HG conditions in terms of sensitivity, accuracy and detectability were obtained with l-cysteine and nitric acid for sample acidification. The proposed method of hydride generation was significantly improved in comparison to application of PN for measuring Sn by ICP OES. The developed method was found to be suitable for monitoring the low content of tin in fresh and canned tomatoes after wet sample digestion in HNO3. The obtained results showed that the highest concentration of tin was found for tomatoes packed in unlacquered cans. It was also determined that the Sn content increases up to twofold in canned tomato samples when stored for 24 h after unlacquered cans are first opened. In all analysed samples, the concentration of tin did not, however, exceed the maximum permissible level for Sn in foods as established by the Commission of the European Communities (Commission Regulation (EC) No 1881).

References

Blunden S, Wallace T (2003) Food Chem Toxicol 41:1651

Boutakhrit K, Crisci M, Bolle F, Van Loco J (2011) Food Addit Contam 28:173

Chen H, Yao W, Wu D, Brindle ID (1996) Spectrochim Acta B 51:1829

Commission Regulation (EC) No. 1881/2006 (2006) Setting maximum levels for certain contaminants in foodstuffs. Official Journal of the European Union

Farías S, Rodríguez RB, Ledesma A, Batistoni DA, Smichowski P (2002) Microchem J 73:79

Feng Y-L, Narasaki H, Chen H-Y, Tian L-C (1997) Fresenius J Anal Chem 357:822

Gutiérrez AM, Pérez-Conde C, Rebollar MP, Diez LMP (1985) Talanta 32:927

Huang X, Zhang W, Han S, Wang X (1997) Talanta 44:817

Knápek J, Herman V, Buchtová R, Vošmerová D (2009) Czech J Food Sci 27:407

Manzoori JL, Amjadi M, Abolhasani D (2006) J Hazard Mater 137:1631

Matusiewicz H, Krawczyk M (2010) Anal Lett 43:2543

Morte ESB, Korn MGA, Saraiva MLMFS, Lima JLFC, Pinto PCAG (2009) Talanta 79:1100

Morte ESB, Barbosa IS, Santos EC, Nóbrega JA, Korn MGA (2012) Food Chem 131:348

Munteanu M, Chirilă E, Stanciu G, Marin N (2010) Ovidius Uni Annals Chem 21:79

Pitzalis E, Maschepa MC, Onor M, D’Ulivo A (2009) Spectrochim Acta B 64:309

Pohl P (2004) Trends Anal Chem 23:87

Qiu DR, Vandecasteele C, Vermeiren K, Dams R (1990) Spectrochim Acta B 45:439

Rafique U, Iqbal S, Faiz S, Hashmi A (2009) J Food Process Preserv 33:186

Rončević S, Benutić A, Nemet I, Gabelica B (2012) Int J Anal Chem. doi:10.1155/2012/376381, Article ID 376381

Trandafir I, Nour V, Ionica ME (2012) Pol J Environ Stud 21:749

Welna M, Lasowska J, Zyrnicki W (2011) J Braz Chem Soc 22:1164

Acknowledgments

This work was financed by a statutory activity subsidy from the Polish Ministry of Science and Higher Education for the Faculty of Chemistry of Wroclaw University of Technology.

Conflict of Interest

Maja Welna declares that she has no conflict of interest. Anna Szymczycha-Madeja declares that she has no conflict of interest. This article does not contain any studies with human or animal subjects.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution License which permits any use, distribution, and reproduction in any medium, provided the original author(s) and the source are credited.

About this article

Cite this article

Welna, M., Szymczycha-Madeja, A. Evaluation of Optimal Conditions for Determination of Low Tin Content in Fresh and Canned Tomato Samples Using Hydride Generation Inductively Coupled Plasma Optical Emission Spectrometry. Food Anal. Methods 7, 127–134 (2014). https://doi.org/10.1007/s12161-013-9608-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12161-013-9608-6