Abstract

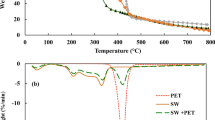

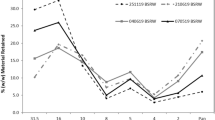

Microalgae have been appeared as excellent source of bioenergy recently in Brunei Darussalam due to the favorable growth conditions, while sewage sludge emerged as major threat to the environment. Therefore, the challenge of sewage sludge management and microalgae utilization has spurred the demand of developing an innovative approach to utilize these sources for commercial applications. Hence, the main objective of this study was to characterize the bioenergy properties of microalgae, sewage sludge, and different blending ratios of microalgae-sewage sludge incorporated with sub-bituminous coal. Among three different blended samples, sample mixture 1 (SM-1) combined with 25% microalgae, 25% sewage sludge, and 50% coal presented the highest calorific value of 16.57 MJ/kg and lowest ash content of 45.61%. Along with this, SM-1 also manifested the highest values for pellet density (1.23 g/cm3) and energy density (20.41 GJ/m3) that can be referred as the most favorable values among all co-pelletized samples for transportation and logistics. Besides the characterization of raw samples, this study also emphasized on elemental analysis of ash content to determine the possibility of fouling and slugging. Ash analysis of all blends represented the major inorganic components aluminum (Al) and silicon (Si). Thermogravimetric analysis of all samples demonstrated the different phases of pyrolysis and combustion within 50 to 900 °C at heating rate of 10 °C/min. It can be concluded that this study recommended SM-1 as a potential feedstock for solid fuel purpose.

Similar content being viewed by others

References

Hosseinizand H, Sokhansanj S, Lim CJ (2018) Co-pelletization of microalgae Chlorella vulgaris and pine sawdust to produce solid fuels. Fuel Process Technol 177:129–139. https://doi.org/10.1016/j.fuproc.2018.04.015

Hossain N, Jalil R (2015) Analyses of bio-energy properties from Malaysian local plants: sentang and sesendok. Asia Pac J Energy Environ 2(6):141–144

Hossain N, Haji Zaini J, Mahlia TMI (2017) A review of bioethanol production from plant-based waste biomass by yeast fermentation. Int J Technol 8(1). https://doi.org/10.14716/ijtech.v8i1.3948

Mahlia TMI, Ismail N, Hossain N, Silitonga AS, Shamsuddin AH (2019) Palm oil and its wastes as bioenergy sources: a comprehensive review. Environ Sci Pollut Res Int 26:14849–14866. https://doi.org/10.1007/s11356-019-04563-x

Cheng HH, Whang LM, Chan KC, Chung MC, Wu SH, Liu CP, Tien SY, Chen SY, Chang JS, Lee WJ (2015) Biological butanol production from microalgae-based biodiesel residues by Clostridium acetobutylicum. Bioresour Technol 184:379–385. https://doi.org/10.1016/j.biortech.2014.11.017

Han SF, Jin WB, Tu RJ, Wu WM (2015) Biofuel production from microalgae as feedstock: current status and potential. Crit Rev Biotechnol 35(2):255–268. https://doi.org/10.3109/07388551.2013.835301

Hossain N, Jalil R (2015) Sugar and bioethanol production from oil palm trunk (OPT). Asia Pac J Energy Environ 2(5):89–92

Hossain N, Mahlia TMI (2019) Progress in physicochemical parameters of microalgae cultivation for biofuel production. Crit Rev Biotechnol 39(6):835–859. https://doi.org/10.1080/07388551.2019.1624945

Hossain N, Zaini J, Jalil R, Mahlia TMI (2018) The efficacy of the period of saccharification on oil palm (Elaeis guineensis) trunk sap hydrolysis. Int J Technol 9(4). https://doi.org/10.14716/ijtech.v9i4.1808

Thangalazhy-Gopakumar S, Al-Nadheri WMA, Jegarajan D, Sahu JN, Mubarak NM, Nizamuddin S (2015) Utilization of palm oil sludge through pyrolysis for bio-oil and bio-char production. Bioresour Technol 178:65–69. https://doi.org/10.1016/j.biortech.2014.09.068

Ahmed A, Hidayat S, Abu Bakar MS, Azad AK, Sukri RS, Phusunti N (2018) Thermochemical characterisation of Acacia auriculiformis tree parts via proximate, ultimate, TGA, DTG, calorific value and FTIR spectroscopy analyses to evaluate their potential as a biofuel resource. Biofuels:1–12. https://doi.org/10.1080/17597269.2018.1442663

Nizamuddin S, Baloch HA, Griffin GJ, Mubarak NM, Bhutto AW, Abro R, Mazari SA, Ali BS (2017) An overview of effect of process parameters on hydrothermal carbonization of biomass. Renew Sust Energ Rev 73:1289–1299. https://doi.org/10.1016/j.rser.2016.12.122

Jones, J.M., Lea-Langton, A.R., Ma, L., Pourkashanian, M., Williams, A.: Combustion of solid biomass: classification of fuels. 9-24 (2014). doi:https://doi.org/10.1007/978-1-4471-6437-1_2

Greinert A, Mrówczyńska M, Szefner W (2019) The use of waste biomass from the wood industry and municipal sources for energy production. Sustainability 11:3083. https://doi.org/10.3390/su11113083

Hossain N, Mahlia TMI, Saidur R (2019) Latest development in microalgae-biofuel production with nano-additives. Biotechnol Biofuels 12(1):125. https://doi.org/10.1186/s13068-019-1465-0

Han X, Niu M, Jiang X, Liu J (2012) Combustion characteristics of sewage sludge in a fluidized bed. Ind Eng Chem Res 51(32):10565–10570. https://doi.org/10.1021/ie3014988

Oladejo J, Shi K, Luo X, Yang G, Wu T (2019) A review of sludge-to-energy recovery methods. Energies 12(1):1–38. https://doi.org/10.3390/en12010060

Hossain N, Mahmud L (2019) Experimental investigation of water quality and inorganic solids in Malaysian urban lake, Taman Tasik Medan Idaman. Lakes Reserv Res Manag 24:107–114. https://doi.org/10.1111/lre.12259

Lin Y, Liao Y, Yu Z, Fang S, Ma X (2017) The investigation of co-combustion of sewage sludge and oil shale using thermogravimetric analysis. Thermochim Acta 653. https://doi.org/10.1016/j.tca.2017.04.003

Huang L, Liu J, He Y, Sun S, Chen J, Sun J, Chang K, Kuo J, Ning X (2016) Thermodynamics and kinetics parameters of co-combustion between sewage sludge and water hyacinth in CO2/O2 atmosphere as biomass to solid biofuel. Bioresour Technol 218:631–642. https://doi.org/10.1016/j.biortech.2016.06.133

Rong H, Wang T, Zhou M, Wang H, Hou H, Xue Y (2017) Combustion characteristics and slagging during co-combustion of rice husk and sewage sludge blends. Energies 10:438. https://doi.org/10.3390/en10040438

Chen G-B, Chatelier S, Lin H-T, Wu F-H, Lin T-H (2018) A study of sewage sludge co-combustion with Australian black coal and shiitake substrate. Energies 11:3436. https://doi.org/10.3390/en11123436

Hossain N, Zaini J, Mahlia TMI, Azad AK (2019) Elemental, morphological and thermal analysis of mixed microalgae species from drain water. Renew Energy 131:617–624. https://doi.org/10.1016/j.renene.2018.07.082

Morni NAH, Radenahmad N, Bakar MSA, Sukri RS, Phusunti N, Azad AK (2018) Potential of sewage sludge as energy recovery via gasification process. IET Conference Proceedings. 7th Brunei International Conference on Engineering and Technology 2018 (BICET 2018). Bandar Seri Begawan, Brunei Darussalam, p 4. https://doi.org/10.1049/cp.2018.1528

AL Hinai M, Azad AK, Abu Bakar MS, Phusunti N (2018) Characterisation and thermochemical conversion of rice husk for biochar production. Int J Renew Energy Res 8(3):1648–1656

Hossain N, Zaini J, Mahlia TMI (2018) Experimental investigation of energy properties for Stigonematales sp. microalgae as potential biofuel feedstock. Int J Sustain Eng:1–8. https://doi.org/10.1080/19397038.2018.1521882

Ahmed A, Abu Bakar MS, Azad AK, Sukri RS, Phusunti N (2018) Intermediate pyrolysis of Acacia cincinnata and Acacia holosericea species for bio-oil and biochar production. Energy Convers Manag 176:393–408. https://doi.org/10.1016/j.enconman.2018.09.041

Sahu Y, Sahu P, Chakradhari S, Patel KS (2016) Combustion characteristics of sewage sludge and algae. Nat Resour 7(4):205–213. https://doi.org/10.4236/nr.2016.74019

Hossain N, Mahlia TMI, Zaini J, Saidur R (2019) Techno-economics and sensitivity analysis of microalgae as commercial feedstock for bioethanol production. Environ Prog Sustain Energy. https://doi.org/10.1002/ep.13157

Hossain N, Zaini J, Indra Mahlia TM (2019) Life cycle assessment, energy balance and sensitivity analysis of bioethanol production from microalgae in a tropical country. Renew Sust Energ Rev 115:109371. https://doi.org/10.1016/j.rser.2019.109371

Tumuluru JS (2016) Specific energy consumption and quality of wood pellets produced using high-moisture lodgepole pine grind in a flat die pellet mill. Chem Eng Res Des 110:82–97. https://doi.org/10.1016/j.cherd.2016.04.007

Gebgeegziabher T, Oyedun AO, Zhang Y, Hui CW (2013) Effective optimization model for biomass drying. In: Kraslawski A, Turunen I (eds) Computer aided chemical engineering. 23rd European Symposium on Computer Aided Process Engineering 32:97–102. https://doi.org/10.1016/B978-0-444-63234-0.50017-8

Wang X, Zhao B, Yang X (2016) Co-pyrolysis of microalgae and sewage sludge: biocrude assessment and char yield prediction. Energy Convers Manag 117:326–334. https://doi.org/10.1016/j.enconman.2016.03.013

Wójcik M, Stachowicz F, Masłoń A (2018) The use of wood biomass ash in sewage sludge treatment in terms of its agricultural utilization. Waste Biomass Valori:1–16. https://doi.org/10.1007/s12649-018-0518-0

Purai A, Rattan VK (2010) Removal of basic green 4 from wastewater by adsorption on biomass ash and activated carbon. Indian Chem Eng 51(4):287–299. https://doi.org/10.1080/00194500903430689

Scimeca M, Bischetti S, Lamsira HK, Bonfiglio R, Bonanno E (2018) Energy dispersive X-ray (EDX) microanalysis: a powerful tool in biomedical research and diagnosis. Eur J Histochem 62(1):2841–2841. https://doi.org/10.4081/ejh.2018.2841

Hasan R, Chong CC, Bukhari SN, Jusoh R, Setiabudi HD (2019) Effective removal of Pb(II) by low-cost fibrous silica KCC-1 synthesized from silica-rich rice husk ash. J Ind Eng Chem 75:262–270. https://doi.org/10.1016/j.jiec.2019.03.034

Hartman M, Svoboda K, Pohořelý M, Trnka O (2005) Combustion of dried sewage sludge in a fluidized-bed reactor. Ind Eng Chem Res 44(10):3432–3441. https://doi.org/10.1021/ie040248n

Jiang L-B, Yuan X-Z, Li H, Chen X-H, Xiao Z-H, Liang J, Leng L-J, Guo Z, Zeng G-M (2016) Co-pelletization of sewage sludge and biomass: thermogravimetric analysis and ash deposits. Fuel Process Technol 145:109–115. https://doi.org/10.1016/j.fuproc.2016.01.027

Phukan MM, Chutia RS, Konwar BK, Kataki R (2011) Microalgae Chlorella as a potential bio-energy feedstock. Appl Energy 88(10):3307–3312. https://doi.org/10.1016/j.apenergy.2010.11.026

Soria-Verdugo A, Goos E, Morato-Godino A, García-Hernando N, Riedel U (2017) Pyrolysis of biofuels of the future: sewage sludge and microalgae – thermogravimetric analysis and modelling of the pyrolysis under different temperature conditions. Energy Convers Manag 138:261–272. https://doi.org/10.1016/j.enconman.2017.01.059

International, A.: ASTM D1895 – 96 (2010) Standard test methods for apparent density, bulk factor, and pourability of plastic materials. In: ISO Standards: R60 Determination of apparent density of molding materials that can be poured from a specified funnel, vol. 60. ASTM International, West Conshohocken, PA

Materials, A.: A5TM D 2974-87 (1987) Standard test methods for moisture, ash, and organic matter of peat and other organic soils. In: Moisture content. Annual Book of ASTM Standards, 1916 Race St., Philadelphia, PA 19103

International, A.: ASTM E711-87(2004) (1987) Standard test method for gross calorific value of refuse-derived fuel by the bomb calorimeter. ASTM International, West Conshohocken, PA

Hossain N, Jalil R, Mahlia TMI, Zaini J (2017) Calorific value analysis of azadirachta excelsa and endospermum malaccense as potential solid fuels feedstock. Int J Technol 8(4):634–643. https://doi.org/10.14716/ijtech.v8i4.9482

International, A.: ASTM E1534-93(2013) (2013) Standard test method for determination of ash content of particulate wood fuels, vol. ASTM E1534-93(2013). ASTM International, West Conshohocken, PA

Laboratories, I.P.T Compositional analysis by thermogravimetric analysis (TGA). In: ASTM E1131, ISO 11358. Intertek Plastics Technology Laboratories, 50 Pearl Street, Pittsfield, MA 01201

Acknowledgment

This research was supported by laboratories of The Faculty of Integrated Technologies and SEM Laboratory of Geology Department, Universiti Brunei Darussalam. The authors would like to thank Dr. Muhammad Saifullah Abu Bakar and Dr. Rahayu Sukmaria Sukri for providing The Brunei Research Council Grant (UBD/BRC/11) as well as Dr. Neeranuch Phusunti from Prince of Songkla University for her assistance in conducting the TGA analysis.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interests

The authors declare that they have no conflict of interest.

Disclaimer

The facts and views in the manuscript are ours and we are totally responsible for authenticity, validity, and originality. We also declare that manuscripts are our original work, and we have not copied from anywhere else. There is no plagiarism in our manuscripts.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

We undertake and agree that the manuscripts submitted to your journal have not been published elsewhere and have not been simultaneously submitted to other journals.

Rights and permissions

About this article

Cite this article

Hossain, N., Morni, N.A.H. Co-pelletization of Microalgae-Sewage Sludge Blend with Sub-bituminous Coal as Solid Fuel Feedstock. Bioenerg. Res. 13, 618–629 (2020). https://doi.org/10.1007/s12155-019-10061-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-019-10061-2