Abstract

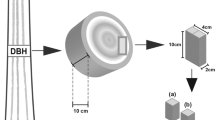

Highly productive short-rotation woody crops is one group of biomass feedstocks that has been identified as having the potential of meeting the goal of reducing the world’s reliance on crude oil. The goal of this project is to quantify the influence of bark on the physical properties, moisture sorption properties, and thermal decomposition of short-rotation (3 years old) Eucalyptus—the most widely planted short-rotation hardwood grown in the world. Results obtained from the study show that the physical properties of ground samples were significantly different between “no-bark” and “with-bark” samples with the bulk density of the with-bark samples decreasing by up to 20 % with a corresponding increase in compressibility of up to 75 %. The moisture sorption rate and the equilibrium moisture relations of the two samples were also significantly different. The susceptibility of no-bark sample to microbial degradation was higher. Thermal decomposition rate and peak temperatures for cellulose and hemicellulose were not affected by the presence of bark. The information obtained from this study will be important in the design and selection of systems for handling, storage, transporting, and thermochemical conversion of short-rotation Eucalyptus.

Similar content being viewed by others

References

EPA (2013) Inventory of U.S. Greenhouse Gas Emissions and Sinks 1990-2011. EPA Report No. 430-R-13-001. US Environmental Protection Agency, Washington

DOE (2011) U.S. Billion-Ton Update: biomass supply for a bioenergy and bioproducts industry. Perlack RD and Tokes BJ (Leads). ORNL/TM-2011/244. Oak Ridge National Laboratory. US Department of Energy, Oak Ridge

Hinchee M, Rottmann W, Mullinax L, Zhang C, Chang S, Cunningham M, Nehra N (2009) Short-rotation woody crops for bioenergy and biofuels applications. In Vitro Cell Dev Biol-Plant 45(6):619–629

Vance E, Loehle C, Wigley B, Weatherford P (2014) Scientific basis for sustainable management of Eucalptus and Populus as short-rotation woody crops in the U.S. Forest 5:901–918

Simpson J, Gordon A, Thevathasan N, Stanturf J, & Nicholas I (2009). Short rotation crops for bioenergy systems—environmental benefits associated with short-rotation woody crops, IEA Bioenergy Task 30: Rotorua, NZ

Jacob S, Perez D, Dupont C, Commandre J, Broust F, Carriau A, Sacco D (2013) Short rotation forestry feedstock: influence of particle size segregation on biomass properties. Fuel 111:820–828

Guidi W, Tozzini C, Bonari E (2009) Estimation of chemical traits in poplar short-rotation coppice at stand level. Biomass Bioenergy 33:1703–1709

Perez D, Guillemain A, Berthelot A, N’guyen-the N, Morogues F, Gomes C (2010) Evaluation of forestry biomass quality for the production of second-generation biofuels. Cellul Chem Technol 44(1–3):1–14

Kumar R, Pandey K, Chandrashekar N, Mohan S (2010) Effect of tree-age on calorific value and other fuel properties of Eucalyptus hybrid. J For Res 21:514–516

Fasina O, Littlefield B (2012) TG-FTIR analysis of pecan shells thermal decomposition. Fuel Process Technol 102:61–66

Lee SB, Fasina O (2009) TG-FTIR analysis of switchgrass pyrolysis. J Anal Appl Pyrolysis 86:39–43

Skreiberg A, Skreiberg O, Sandquist J, Sorum L (2011) TGA and macro-TGA characterization of biomass fuels and fuel mixtures. Fuel 90:2182–2197

Bell L, Labuza T (2000) Moisture sorption: practical aspects of isotherm measurement and use, 2nd edn. American Association of Cereal Chemists, Inc., St. Paul

Karunanithy C, Muthukumarappan K, Donepudi A (2013) Moisture sorption characteristics of switchgrass and prairie cord grass. Fuel 103:171–178

Colley Z, Fasina O, Bransby D, Lee Y (2006) Moisture effect on the physical characteristics of switchgrass pellets. Trans ASABE 49:1845–1851

He X, Lau A, Sokhansanj S, Lim J, Bi X, Melin S, Keddy T (2013) Moisture sorption isotherms and drying characteristics of aspen (Populus tremuloides). Biomass Bioenergy 57:161–167

Arabhosseini A, Huisman W, Muller J (2010) Modeling of the equilibrium moisture content (EMC) of miscanthus (Miscanthus x giganteus). Biomass Bioenergy 34:411–416

Bonner I, Kenney K (2013) Moisture sorption behavior characteristics and modeling of energy sorghum (Sorghum bicolor L.) Moench). J Stored Prod Res 52:128–136

Fasina O (2008) Physical properties of peanut hull pellets. Bioresour Technol 99:1259–1266

Karunanithy C, Muthukumarappan K, Donepudi A (2013) Moisture sorption characteristics of corn stover and big bluestem. J Renew Energy 2013:1–12

Rockwood D, Rudie A, Ralph S, Zhu J, Winandy J (2008) Energy product options for eucalyptus species grown as short rotation woody crops. Int J Mol Sci 9:1361–1378

ASTM (2007) Standard E1757. Standard practice for preparation of biomass for compositional analysis. American Society of Testing Materials, New York

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D (2008) Determination of ash in biomass by laboratory analytical procedure. National Renewable Energy Laboratory Report No NREL/TP-51-42622. Golden, CO. http://www.nrel.gov/biomass/analytical_procedures.html

ISO (2010) Standard 562: hard coal and coke. Determination of Volatile Matter. International Standards Organization, Geneva, Switzerland

Sluiter A, Hames B, Ruiz R, Scarlata C, Sluiter J, Templeton D, Crocker D (2012) Determination of structural carbohydrates and lignin in biomass—laboratory analytical procedure. Report No NREL/TP-510-42618. NREL, Golden

ISO (2006) Standard 16993: solid biofuels—calculation of analyses to different bases. International Standards Organization, Geneva, Switzerland

ASTM (2008) Standard E1756. Standard test method for determination of total solids in biomass. American Society of Testing Materials, New York

Bernhart M, Fasina O (2009) Moisture effect on the storage, handling and flow properties of poultry litter. Waste Manag 29:1392–1398

SAS (2013) SAS user’s guide: statistics. Statistical Analysis System Inc., Cary

Senelwa K, Sims R (1999) Fuel characteristics of short rotation forest biomass. Biomass Bioenergy 17:127–140

Littlefield B, Fasina O, Shaw J, Adhikari S, Via B (2011) Physical and flow properties of pecan shells—particle size and moisture effects. Powder Technol 212:173–180

Probst K, Ambrose K, Pinto R, Bali R, Krishnakumar P, Ileleji K (2013) The effect of moisture content on the grinding performance of corn and corncobs by hammermilling. Trans ASABE 56:1025–1033

Teunou E, Fitzpartrick J, Synnott E (1999) Characterization of food powder flowability. J Food Eng 39:31–37

Fayed M, Skocir T (1997) Mechanical conveyors: selection and operation. Technomic Publishing Company Inc., Lancaster

ASABE (2014) ANSI/ASABE S448.2 Standard: thin-layer drying of agricultural crops. ASABE, St. Joseph

Basunia M, Abe T (2005) Thin-layer re-wetting of rough rice at low and high temperatures. J Stored Prod Res 41:163–173

Kashaninejad M, Dehghani A, Kashiri M (2009) Modeling of wheat soaking using two artificial neural netwrosk (MLP and RBF). J Food Eng 91:602–607

Wilhelm L, Suter D, Brusewitz G (2004) Food and process engineering technology. ASABE, St. Joseph

Mishchenko A, Yakimov N, Potashev K, Breus V, Breus I (2007) The equation of vapor-phase sorption on heterogeneous surfaces with local Guggenheim-Anderson-De Boer model. Colloids Surf A Physicochem Eng Asp 296:182–190

Lam P, Sokhansanj S, Bi X, Lim J, Larsson S (2012) Drying characteristics and equilibrium moisture content of steam-treated Douglas fir (Pseudotsuga menziesii L.). Bioresour Technol 116:396–402

Mello L, Mali S (2014) Use of malt bagasse to produce biodegradable baked foams made from cassava starch. Ind Crop Prod 55:187–193

Cardoso J, Pena R (2014) Hygroscopic behavior of banana (Musa spp. AAA) flour in different ripening stages. Food Bioprod Process 92:73–79

Goneli A, Comea P, Oliveira G, Afonso P (2013) Water sorption properties of coffee fruits, pulped and green coffee. LWT Food Sci Technol 50:386–391

Quirijns E, van Boxtel A, van Loon W, van Straten G (2005) Sorption isotherms. GAB parameters and isosteric heat of sorption. J Sci Food Agric 85:1805–1814

Moraga G, Martinex-Navarrete N, Chiralt A (2006) Water sorption isotherms and phase transitions in kiwifruit. J Food Eng 72:147–156

Souza BS, Moreira AP, Teixeira AM (2009) TG–FTIR coupling to monitor the pyrolysis products from agricultural residues. J Therm Anal Calorim 87:638–642

Tsamba A, Yang W, Blasiak W (2006) Pyrolysis characteristics and global kinetics of coconut and cashew nut shells. Fuel Process Technol 87:523–530

Meszaros E, Varhegyi G, Jakab E (2004) Thermogravimetric and reaction kinetic analysis of biomass samples from an energy plantation. Energy Fuel 18:497–507

Idris SS, Rahman NA, Ismail K, Alias AB, Rashid ZA, Aris MJ (2010) Investigation on thermochemical behavior of low rank Malaysian coal, oil palm biomass and their blends during pyrolysis via thermogravimetric analysis (TGA). Bioresour Technol 101:4584–4592

Pang C, Gaddipatti S, Tucker G, Lester E, Wu T (2014) Relationship between thermal behavior of lignocellulosic components and properties of biomass. Bioresour Technol 172:312–320

Zhou H, Long Y, Meng A, Li Q, Zhang Y (2013) The pyrolysis simulation of five biomass species by hemicellulose, cellulose and lignin based thermogravimetric curves. Thermochim Acta 566:36–43

Jeguirim M, Bikai J, Elmay Y, Limousy L, Njeugna E (2014) Thermal characterization and pyrolysis kinetics of tropical biomass feedstocks for energy recovery. Energy Sustain Dev 23:188–193

Acknowledgments

We acknowledge funding from USDA-NIFA Project: Southeast Partnership for Integrated Biomass Supply Systems (IBSS), NSF Research Experience for Undergraduates (REU) Project: Biofuels and Bioproducts from Lignocellulosic Biomass (Award No. 1149940), and Alabama Agriculture Experiment Station Hatch Funding.

Conflict of interest

We do not have conflict of interests regarding the conduct of this research.

Statement regarding ethical standards

The authors of this manuscript hereby declare to the BioEnergy Research Journal that we are in compliance with ethical standards with regard to the contents of the manuscript. We did not use humans or animals as test subjects while conducting the study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Goncalves, B., Till, D., Fasina, O. et al. Influence of Bark on the Physical and Thermal Decomposition Properties of Short-Rotation Eucalyptus . Bioenerg. Res. 8, 1414–1423 (2015). https://doi.org/10.1007/s12155-015-9606-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12155-015-9606-1