Abstract

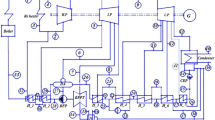

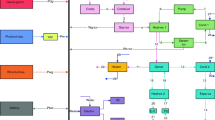

In this study, a combined cycle power plant with a nominal capacity of 500 MW, including two gas turbine units and one steam turbine unit, is considered by a mathematical model. This study is carried out to optimize three objective functions of exergy efficiency, CO2 emission and produced power costs. This multi-objective optimization has been carried out by using the Non-Dominated Sorting Genetic Algorithm (NSGA-II). The results indicate that the efficiency of the combined cycle power plant depends on the design parameters including gas turbine input temperature, compressor pressure ratio, and pinch point temperature. Furthermore, any change occurring in these settings may lead to noticeable changes in objective functions, so that the efficiency of this power plant is increased after optimization by up to 8.12 %, and its heat rate is correspondingly reduced from 7233 (kJ/kWh) to 7023 (kJ/kWh). Similarly, exergy destruction in the total system shows a reduction by 7.23%.

Similar content being viewed by others

Abbreviations

- \( c \) :

-

cost per exergy unit ($/MJ)

- \( c_{\text{f}} \) :

-

cost of fuel per energy unit ($/MJ)

- \( \dot{C} \) :

-

cost flow rate ($/s)

- \( c_{p} \) :

-

specific heat at constant pressure (kJ/kg K)

- \( CRF \) :

-

capital recovery factor

- \( E \) :

-

exergy \( \left( {\frac{{\text{MJ}}}{{\text{kg}}}} \right) \)

- f :

-

exergoeconomic factor

- \( \dot{E} \) :

-

exergy flow rate (MW)

- \( \dot{E}_{D} \) :

-

exergy destruction rate (MW)

- \( {\dot{\text{E}}}_{\text{W}} \) :

-

exergy rate of work (MW)

- \( e \) :

-

specific exergy (kJ/kg)

- \( {\text{e}}_{\text{f}} \) :

-

chemical exergy of the fuel (kJ/kg)

- \( i \) :

-

annual interest rate (%)

- \( {\text{h}} \) :

-

specific enthalpy (kJ/kg)

- \( {\text{h}}_{0} \) :

-

specific enthalpy at environmental state (kJ/kg)

- LHV:

-

lower heating value (kJ/kg)

- \( \dot{m} \) :

-

mass flow rate (kg/s)

- \( {\text{n}} \) :

-

number of years

- \( {\text{N}} \) :

-

number of hours of plant operation per year

- \( {\text{PP}} \) :

-

pinch point

- \( \dot{Q} \) :

-

heat transfer rate (kW)

- \( r_{AC} \) :

-

compressor pressure ratio

- \( s \) :

-

specific entropy (kJ/kg K)

- \( s_{0} \) :

-

specific entropy at environmental state (kJ/kg K)

- \( T_{0} \) :

-

absolute temperature (K)

- \( \dot{W}_{net} \) :

-

net power output (MW)

- \( Z \) :

-

capital cost of a component ($)

- \( \dot{Z} \) :

-

capital cost rate ($/s)

- \( \eta \) :

-

isentropic efficiency

- \( \xi \) :

-

coefficient of fuel chemical exergy

- \( \sigma \) :

-

standard deviation

- \( \Phi \) :

-

maintenance factor

- π:

-

dimensionless pressure values

- θ:

-

dimensionless temperature values

- \( a \) :

-

air

- \( {\text{AC}} \) :

-

air compressor

- \( {\text{CC}} \) :

-

combustion chamber

- \( {\text{ch}} \) :

-

chemical

- \( {\text{Cond}} \) :

-

condenser

- D:

-

exergy destruction

- \( {\text{f}} \) :

-

fuel

- \( {\text{GT}} \) :

-

gas turbine

- \( {\text{HP}} \) :

-

high pressure

- \( {\text{HRSG}} \) :

-

heat recovery steam generator

- i :

-

ith trial vector

- k :

-

kth component

- \( {\text{LP}} \) :

-

low pressure

- \( {\text{ph}} \) :

-

physical

- tot:

-

total

- \( {\text{ST}} \) :

-

steam turbine

- sys:

-

system

- \( {\text{w}} \) :

-

water

References

Tsatsaronis G, Lin L and Pisa J 1993 Exergy costing in exergoeconomics. Journal of Energy Resource—ASME 115: 9–16

Sahoo P K 2008 Exergoeconomic analysis and optimization of a cogeneration system using evolutionary programming. Applied Thermal Engineering 28(13): 1580–8

BarzegarAvval H, Ahmadi P, Ghaffarizadeh A and Saidi M H 2011 Thermoeconomic–environmental multiobjective optimization of a gas turbine power plant with preheater using evolutionary algorithm. International Journal of Energy Research 35: 389–403

Si N, Zhao Z, Su S, Han P, Sun Z, Xu J, Cui X, Hu S, Wang Y, Jiang L, Zhou Y, Chen G and Xiang J 2017 Exergy analysis of a 1000 MW double reheat ultra-supercritical power plant. Energy Conversion and Management 147: 155–165

Abuelnuor A A A, Saqr K M, Mohieldein S A A, Dafallah K A, Abdullah M M, Abdullah Y and Nogoud M 2017 Exergy analysis of Garri “2” 180 MW combined cycle power plant. Renewable and Sustainable Energy Reviews 79: 960–969

Lozano M A and Valero A 1993 Theory of the exergetic cost. Energy 18:939–60

Erlach B, Serra L and Valero A 1999 Structural theory as standard for thermoeconomics. Energy Conversion and Management 40: 1627–1649

Frangopoulos C A 1987 Thermo-economic functional analysis and optimization. Energy 12: 563–571

Frangopoulos C A 1991 Intelligent functional approach: a method for analysis and optimal synthesis–design–operation of complex systems. Journal of Energy Environment Economics 1: 267–74

Lazzaretto A and Tsatsaronis G 2006 SPECO: “a systematic and general methodology for calculating efficiencies and costs in thermal systems”. Energy 31:1257–89

Von Spakovsky M R 1994 Application of engineering functional analysis to the analysis and optimization of the CGAM problem. Energy 19: 343–64

Von Spakovsky M R and Evans R B 1993 Engineering functional analysis – Parts I and II. Journal of Energy Resource—ASME 115: 86–99

Pratap S, Daultani Y, Tiwari M K and Mahanty B 2018 Rule based optimization for a bulk handling port operations. Journal of Intelligent Manufacturing 29(2): 287–311

Chan F T S, Jha A and Tiwari M K 2016 Bi-objective optimization of three echelon supply chain involving truck selection and loading using NSGA-II with heuristics algorithm. Applied Soft Computing Journal 38: 978–987

Chaube A, Benyoucef L and Tiwari M K 2012. An adapted NSGA-2 algorithm based dynamic process plan generation for a reconfigurable manufacturing system. Journal of Intelligent Manufacturing 23(4): 1141–1155

Dixit V, Seshadrinath N and Tiwari M K 2016. Performance measures based optimization of supply chain network resilience: A NSGA-II + Co-Kriging approach. Computers and Industrial Engineering 93: 205–214

Tiwari A, Chang P C and Tiwari M K 2012 A highly optimised tolerance-based approach for multi-stage, multi-product supply chain network design. International Journal of Production Research 50(19): 5430–5444

Mogale D G, Kumar M, Kumar S K and Tiwari M K 2018 Grain silo location-allocation problem with dwell time for optimization of food grain supply chain network. Transportation Research Part E: Logistics and Transportation Review 111: 40–69

Dolgui A, Tiwari M K, Sinjana Y, Kumar S K and Son Y J 2018 Optimising integrated inventory policy for perishable items in a multi-stage supply chain. International Journal of Production Research 56(1–2): 902–925

Patne K, Shukla N, Kiridena S and Tiwari M K 2018 Solving closed-loop supply chain problems using game theoretic particle swarm optimisation. International Journal of Production Research 56(17): 5836–5853

Maiyar L M, Cho S J, Tiwari M K, Thoben K D and Kiritsis D 2018 Optimising online review inspired product attribute classification using the self-learning particle swarm-based Bayesian learning approach. International Journal of Production Research. Taylor and Francis Ltd. https://doi.org/10.1080/00207543.2018.1535724

Maiyar L M and Thakkar J J 2017. A combined tactical and operational deterministic food grain transportation model: Particle swarm based optimization approach. Computers and Industrial Engineering 110: 30–42

Maiyar L M, Thakkar J J, Awasthi A and Tiwari M K 2015. Development of an effective cost minimization model for food grain shipments. In: IFAC-PapersOnLine 28: 881–886

Jawad H, Jaber M Y and Nuwayhid R Y 2018 Improving supply chain sustainability using exergy analysis. European Journal of Operational Research 269(1): 258–271

Bilgen S and Sarikaya I 2015 Exergy for environment, ecology and sustainable development. Renewable and Sustainable Energy Reviews.

Mogale D G, Kumar,S K and Tiwari M K 2018 An MINLP model to support the movement and storage decisions of the Indian food grain supply chain. Control Engineering Practice 70: 98–113

Mogale D G, Kumar M, Kumar S K and Tiwari M K 2018 Grain silo location-allocation problem with dwell time for optimization of food grain supply chain network. Transportation Research Part E: Logistics and Transportation Review 111: 40–69

Di Somma M, Yan B, Bianco N, Graditi G, Luh P B, Mongibello L and Naso V 2017. Design optimization of a distributed energy system through cost and exergy assessments. Energy Procedia 105: 2451–2459

Bahlouli K 2018 Multi-objective optimization of a combined cycle using exergetic and exergoeconomic approaches. Energy Conversion and Management 171: 1761–1772

Hoseinzadeh S, Ghasemiasl R, Havaei D and Chamkha A J 2018 Numerical investigation of rectangular thermal energy storage units with multiple phase change materials. Journal of Molecular Liquids 271: 655–660

Hoseinzadeh S, Moafi A, Shirkhani A and Chamkha A J 2019 Numerical validation heat transfer of rectangular cross-section porous fins. Journal of Thermophysics and Heat Transfer 1–7. https://doi.org/10.2514/1.T5583

Hoseinzadeh S, Sahebi S A R, Ghasemiasl R and Majidian A R 2017 Experimental analysis to improving thermosyphon (TPCT) thermal efficiency using nanoparticles/based fluids (water). European Physical Journal Plus 132(5). https://doi.org/10.1140/epjp/i2017-11455-3

Yari A, Hosseinzadeh S, Golneshan A A and Ghasemiasl R 2015 Numerical simulation for thermal design of a gas water heater with turbulent combined convection (p. V001T03A007). ASME International. https://doi.org/10.1115/ajkfluids2015-3305

Yousef Nezhad M E and Hoseinzadeh S 2017 Mathematical modelling and simulation of a solar water heater for an aviculture unit using MATLAB/SIMULINK. Journal of Renewable and Sustainable Energy 9(6). https://doi.org/10.1063/1.5010828

Hoseinzadeh S, Hadi Zakeri M, Shirkhani A and Chamkha A J 2019 Analysis of energy consumption improvements of a zero-energy building in a humid mountainous area. Journal of Renewable and Sustainable Energy 11(1). https://doi.org/10.1063/1.5046512

Hoseinzadeh S and Azadi R 2017 Simulation and optimization of a solar-assisted heating and cooling system for a house in Northern of Iran. Journal of Renewable and Sustainable Energy 9(4). https://doi.org/10.1063/1.5000288

Javadi M A and Ghomashi H 2016 Thermodynamics analysis and optimization of Abadan combined cycle power plant. Indian Journal of Science and Technology 9

Habibi H, Yari A, Hosseinzadeh S and Burkhani S D 2016 Numerical study of fluid flow around a diver helper. International Journal of Recent advances in Mechanical Engineering (IJMECH) 5(1). https://doi.org/10.14810/ijmech.2016.5105

Hosseinzadeh S, Galogahi M R and Bahrami A 2014 Performance prediction of a turboshaft engine by using of one dimensional analysis. International Journal of Recent Advances in Mechanical Engineering 3: 99–108

Yari A, Hosseinzadeh S and Galogahi M R, 2014 Two-dimensional numerical simulation of the combined heat transfer in channel flow. International Journal of Recent Advances in Mechanical Engineering 3: 55–67

Hosseinzadeh S, Yari A, Abbasi E and Absalan F 2014 The numerical study of channel flow in turbulent free convection with radiation and blowing. International Journal of Recent Advances in Mechanical Engineering 3: 11–26

Hosseinzadeh S, Yari A, Abbasi E and Absalan F 2014 The numerical study of channel flow in turbulent free convection with radiation and blowing. International Journal of Recent Advances in Mechanical Engineering 3: 11–26

Kohzadi H, Shadaram A and Hoseinzadeh S 2018 Improvement of the centrifugal pump performance by restricting the cavitation phenomenon. Chemical Engineering Transactions 71: 1369–1374

Hosseinzadeh S, Ostadhossein R, Mirshahvalad H R and Seraj J 2017 Using simpler algorithm for cavity flow problem. An International Journal (MECHATROJ) 1

Ghasemi A, Dardel M, Ghasemi M H and Barzegari M M 2013 Analytical analysis of buckling and post-buckling of fluid conveying multi-walled carbon nanotubes. Appl. Math. Model. 37: 4972–4992

Ghasemi A, Dardel M and Ghasemi M H 2012 Control of the non-linear static deflection experienced by a fluid-carrying double-walled carbon nanotube using an external distributed load. Proceedings of the Institution of Mechanical Engineers, Part N: Journal of Nanoengineering and Nanosystems 226: 181–190

Ghasemi A, Dardel M and Ghasemi M H 2015 Collective effect of fluid’s coriolis force and nanoscale’s parameter on instability pattern and vibration characteristic of fluid-conveying carbon nanotubes. Journal of Pressure Vessel Technology 137: 031301-10

Bahrami A, Hosseinzadeh S, Ghasemiasl R and Radmanesh M 2015 Solution of non-Fourier temperature field in a hollow sphere under harmonic boundary condition. Applied Mechanics and Materials 772: 197–203

Eftari M, Hoseinzadeh S, Javaniyan H and Emadi M F T 2012 Analytical solution for free convection non-Newtonian flow between two vertical sheets. World Applied Sciences Journal 16 (Special Issue of Applied Math): 01–06

Hoseinzadeh S 2012 Experimental investigation on thermal performance using nanofluid. August Archives Des Sciences Journal 65(8): 22–29

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Javadi, M.A., Hoseinzadeh, S., Khalaji, M. et al. Optimization and analysis of exergy, economic, and environmental of a combined cycle power plant. Sādhanā 44, 121 (2019). https://doi.org/10.1007/s12046-019-1102-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12046-019-1102-4