Abstract

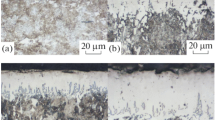

In the present study, AISI 8620 steel was plasma paste borided by using various B2O3 paste mixture. The plasma paste boriding process was carried out in a dc plasma system at temperatures of 973, 1023 and 1073 K for 2, 5 and 7 h in a gas mixture of 70% H2 -30% Ar under a constant pressure of 10 mbar. The properties of the boride layer were evaluated by optical microscopy, X-ray diffraction, Vickers micro-hardness tester and the growth kinetics of the boride layers. X-ray diffraction analysis of boride layers on the surface of the steel revealed FeB and Fe2B phases. Depending on temperature and layer thickness, the activation energies of boron in steel were found to be 124.7 kJ/mol for 100% B2O3.

Similar content being viewed by others

References

Bartsch K & Leonhardt A 1999 Formation of iron boride layers on steel by d.c.-plasma boriding and deposition processes. Surf. Coat Technol. 116(119): 386–390

Bejar M A & Henríquez R 2009 Surface hardening of steel by plasma- electrolysis boronizing. Mater. Des. 30: 1726–1728

Bindal C & Ucisik A H 1999 Characterization of borides formed on impurity-controlled chromium-based low alloy steels. Surf. Coat Technol. 122: 208–213

Buijnsters J G, Shankar P, Gopalakrishnan P, Van Enckevort W J P, Schermer J J, Ramakrishnan S S and Ter Meulen J J 2003 Diffusion-modified boride interlayers for chemical vapour deposition of low-residual-stress diamond films on steel substrates. Thin Solid Films. 426: 85–93

Campos I, Bautista O, Ramírez G, Islas M, de la Parra J and Zuñiga L 2005 Effect of boron paste thickness on the growth kinetics of Fe2B boride layers during the boriding process. Appl. Surf. Sci. 243: 429–436

Chen X J, Yu L G, Khor K A and Sundararajan G 2008 The effect of boron-pack refreshment on the boriding of mild steel by the spark plasma sintering (SPS) process. Surf. Coat. Technol. 202: 2830–2836

Culha O, Toparli M, Sahin S and Aksoy T 2008‘Characterization and determination of Fe x B layers’ mechanical properties. Mater. Proces. Technol. 206: 231–240

Davis J A, Wilbur P J, Williamson D L, Wei R and Vajo J J 1998 Ion implantation boriding of iron and AISI M2 steel using a high-current density, low energy, broad-beam ion source. Surf. Coat. Technol. 103–104: 52–57

Dong M, Bao-luo S and Xin Z 2010 Effects of boronizing on mechanical and dry-sliding wear properties of CoCrMo alloy. Mater. Des. 31: 3933–3936

Efe G C, Ipek M, Ozbek I and Bindal C 2008 Kinetics of borided 31CrMoV9 and 34CrAlNi7 steels. Mater. Charact. 59: 23–31

Genel K 2006 Boriding kinetics of H13 steel. Vacuum. 80: 451–457

Genel K, Ozbek I and Bindal C 2003 Kinetics of boriding of AISI W1 steel. Mater. Sci. and Eng. A. 347: 311–314

Gunes I, Ulker S and Taktak S 2011 Plasma paste boronizing of AISI 8620, 52100 and 440C steels. Mater. Des. 32: 2380–2386

Kartal G, Eryilmaz O L, Krumdick G, Erdemir A and Timur S 2011 Kinetics of electrochemical boriding of low carbon steel. Appl. Surf. Sci. 257: 6928–6934

Khor K A, Yu L G and Sundararajan G 2005 Formation of hard tungsten boride layer by spark plasma sintering boriding. Thin Solid Films. 478: 232–237

Kayali Y, Gunes I and Ulu S 2012 Diffusion kinetics of borided AISI 52100 and AISI 440C steels. Vacuum. 86: 1428–1434

Lou D C, Solberg J K, Akselsen O M and Dahl N 2009 Microstructure, property investigation of paste boronized pure nickel, Nimonic 90 superalloy. Mat. Chemistry and Phys. 115: 239–244

Nam K S, Lee K H, Lee S R and Kwon S C 1998 A study on plasma-assisted boriding of steels. Surf. Coat Technol. 98: 886–890

Oliveria C K N, Casteletti L C, Lombardin Neto A, Totten G E and Heck S C 2010 Production and Characterization of Boride Layers on AISI D2 Tool Steel. Vacuum. 84: 792–796

Ozbek I, Konduk B A, Bindal C and Ucisik A H 2002 Characterization of borided AISI 316L stainless steel implant. Vacuum. 65: 521–525

Ozdemir O, Omar M A, Usta M, Zeytin S, Bindal C and Ucisik A H 2008 An investigation on boriding kinetics of AISI 316 stainless steel. Vacuum. 83: 175–179

Rodríguez C E, Laudien G, Biemer S, Rie K-T and Hoppe S 1999 Plasma-assisted boriding of industrial components in a pulsed d.c. glow discharge. Surf. Coat Technol. 116–119: 229–233

Sahin S, Meric C and Saritas S 2010 Production of ferroboron powders by solid boronizing method. A Powder Technol. 21: 483–487

Sen S, Ozbek I, Sen U and Bindal C 2001 Mechanical behavior of borides formed on borided cold work tool steel. Surf. Coat Technol. 135: 173–177

Sen S, Sen U and Bindal C 2005a An approach to kinetic study of borided steels. Surf. Coat Technol. 191: 274–85

Sen S, Sen U and Bindal C 2005b The growth kinetics of borides formed on boronized AISI 4140 steel. Vacuum. 77: 195–202

Shrivastava S, Jain A, Tarey RD, Avasthi DA, Kabiraj D, Senapati L and Mehta G K 1996 Hardening of steel by Boron Ion Implantation-Dependence on Phase Composition. Vacuum. 47: 247–249

Sinha A K 1991 Boronizing, ASM Handbook, J. Heat Treat., USA

Tabur M, Izciler M, Gul F and Karacan I 2009 Abrasive wear behavior of boronized AISI 8620 steel. Wear. 266: 1106–1112

Taktak S 2006 A study on the diffusion kinetics of borides o boronized Cr-based steels. J. Mater. Sci. 41: 7590–7596

Torun O & Celikyurek I 2009 Boriding of diffusion bonded joints of pure nickel to commercially pure titanium. Mater. Des. 30: 1830–1834

Ulker S, Gunes I and Taktak S 2011 Investigation tribological behaviour of plasma paste boronized of AISI 8620, 52100 and 440C steels. Indian J. Eng. Mater. Sci. 18: 370–377

Yan P X, Wei Z Q, Wen X L, Wu Z G, Xu J W, Liu W M and Tian J 2002 Post boronizing ion implantation of C45 steel. Appl. Surf. Sci. 195: 74–79

Yoon J H, Jee Y K and Lee S Y 1999 Plasma paste boronizing treatment of the stainless steel AISI 304. Surf. Coat. Technol. 112: 71–75

Yu L G, Khor K A and Sundararajan G 2002 Boriding of mild steel using the spark plasma sintering (SPS) technique. Surf. Coat. Technol. 157: 226–230

Yu L G, Chen X J, Khor K A and Sundararajan G 2005 FeB/Fe2B phase transformation during SPS pack-boriding: Boride layer growth kinetics. Acta Mater. 53: 2361–2368

Acknowledgements

This study was supported by the National Boron Research Institute, Turkey as BOREN project numbered ‘2009-Ç0246’.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

GUNES, I., TAKTAK, I., BINDAL, C. et al. Investigation of diffusion kinetics of plasma paste borided AISI 8620 steel using a mixture of B 2 O 3 paste and B 4 C/SiC. Sadhana 38, 513–526 (2013). https://doi.org/10.1007/s12046-013-0136-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-013-0136-2