Abstract

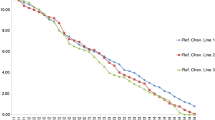

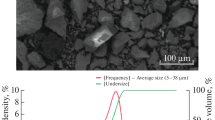

This paper presents the possibility of restoration of worn contact surfaces of rollers for continuous casting of steel. Permanent effort of steel producers to extend the lifespan of these components requires the implementation of new filler materials or modifying technological renovation processes to reduce the economic costs. This matter seems to be very important for the world leaders in steel production, e.g., ArcelorMittal, Tata Steel, but also for smaller concerns such as Magnitogorsk Iron and Steel Works, Salzgitter, etc. Renovation of continuous steel casting rollers, made of X12Cr13 EN 10088-1-97, was realised using submerged arc surfacing technology. Worn surface of roller was machined and surfaced using one interlayer and two cover layers. The quality of deposited layers was verified using non-destructive and destructive tests. The influence of filler material on the tribological properties of contact surfaces of deposited layers was analysed by abrasive wear test. Studies were made in the influence of surfacing parameters on cladding metal mixing (mixed) with base metal and also influence of heat introduced by welding using metallographic analysis. The experiments confirmed very good wear resistance of the applied filler metal due to dispersion strengthening caused by finely dispersed carbides and nitrides in the weld coating. The measures to be taken into account in renovation of rollers using hard surfacing, as well as the development of research in this area were also given. The experiments have confirmed that parameters used are suitable for studying filler materials.

Similar content being viewed by others

References

Bhattacharya A K and Sambasivam D 2009 Optimization of oscillation parameters in continuous casting process of steel manufacturing: Genetic algorithms versus differential evolution. Evolutionary Computation, W P Santos (ed.) Vienna, Austria: InTech, 572

Blaškovitš P and Čomaj M 2006 Renovation by cladding and thermal spraying (in Slovak), Bratislava: STU Bratisava

Blaškovitš P, Grinberg N A, Suchánek J, Gouveia H, Reis M, Drucová J, Sukubová I, Farkas T and Kasala M 2001 New hardfacing materials for abrasive and erosive conditions. Proc. IIW, Ljubljana

Coe F R 1973 Welding Steels Without Hydrogen Cracking, Technical Report. Abington: The Welding Institute

Čomaj M and Šefčík D 1999 Cladding of continuous stell casting rollers. Proc. XXVII National Conference and Discussion forum Welding, 68

Gooch T G 1977 Welding martensitic stainless steels. TWI Res. Bull., 18: 343

Hrivňák I 1972 Influence of globular inclusions of silicate of plastic properties welding metal. Welding (in Slovak) 21: 295

Kasala J, Pernis R and Mäsiar H 2009 An Application of Robust Parameter Design using Taguchi Method, 2009. Proc. 9th International Foundrymen Conference: Innovative Materials and Advanced Concepts of Metal Casting Production, Zagreb, 6

Kasala J, Mäsiar H and Pernis I 2010 Investigation of selected thermo-physical Properties in the Co-based superalloy: Experiment and Application Study. Arch. Foundry Eng. 10: 203

Mazumdar S and Ray S K 2001 Solidification control in continuous casting of steel. Sādhanā 26(1,2): 179–198

Nakamura H, Naiki T and Okabayashi H 1969 Stress relief cracking in the HAZ. Technical Report IIW-IX-648-69. Doc. IIW-II-612-69

Slavkovský F 1987 Renovation of devices for continuous stell casting. Proc. New Directions for Development Processes of Engineering Technology, 101

Šúň R 2007 New technological progresses of continual casting rollers renovation. Diploma thesis, Technical University of Košice

Viňáš J 2003 The study of welds -on surfaces making for the purpose of increasing product lifespan, Ph.D. thesis, Technical University of Košice

Viňáš J and Kaščák L’ 2008 Possibilities of using welding-on technologies in crane Wheel renovation. Bull. Mater. Sci. 31: 125

Viňáš J and Kačšák L’ 2008 Revitalization of crane wheel using cladding technology. Zavarivanje i zavarene konstrukcije 53(1): 3–16

VUZ-PI 2011a Welding Research Institute - Industrial institute of SR. Catalogue of products: Welding wires 2011 http://www.vuz.sk/en/home/Production/Welding-consumables/Tubular-cored-wires-and-rods

VUZ-PI 2011b Welding Research Institute - Industrial institute of SR. Catalogue of products: Welding wires 2011 http://www.vuz.sk/en/home/Production/Welding-consumables/Fluxes-for-welding-and-surfacing

Zeke J and Jánošiová J 1975 Coefficients of Cr oxidation as metallurgical characteristics of welding fluxes. Welding (in Slovak) 24: 193

Zeke J and Mikula K 1973 Mathematical model of expression manganese reaction during submerged arc welding. Research report, VUZ, Bratislava

Acknowledgement

This study was supported by the Scientific Agency of Slovak Republic VEGA (project no. 1/0824/12).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

VIŇÁŠ, J., BREZINOVÁ, J. & GUZANOVÁ, A. Analysis of the quality renovated continuous steel casting roller. Sadhana 38, 477–490 (2013). https://doi.org/10.1007/s12046-013-0119-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12046-013-0119-3