Abstract

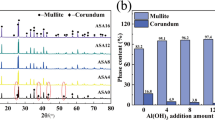

Two different commercially available sources of alumina and silica were used to study the formation and densification behaviour of mullite prepared by solid-oxide reaction technique in a single firing. Phase analysis and densification studies were carried out on the samples sintered between 1200 and \(1600^{{\circ }}\hbox {C}\). Effect of addition of 1–6 wt% MgO on the sintered mullite ceramics was also studied. MgO was found to improve the density values for all the compositions till 4 wt% and with higher addition it deteriorated, mainly due to higher extent of liquid phase formation. Mullite formation was found to start below \(1200^{{\circ }}\hbox {C}\) and constituent oxides were found even at \(1600^{{\circ }}\hbox {C}\); however, addition of 4 wt% MgO was found to complete the mullite formation at \(1600^{{\circ }}\hbox {C}\) for all the compositions. Microstructural studies showed grain growth in the compositions containing MgO and higher impurities due to formation of greater extent of liquid phase.

Similar content being viewed by others

References

Torrecillias R, De Aza S, Moya J S, Epicier T and Fantozzi G 1990 J. Mater. Sci. Lett. 9 1400

Skoog A J and Moore R E 1998 Am. Ceram. Soc. Bull. 67 1180

Aksay I A, Dabbs D M and Sarlkaya M 1991 J. Am. Ceram. Soc. 74 2343

Hildmann B and Schneider H 2005 J. Am. Ceram. Soc. 88 2879

Zhang Y, Ding Y, Gao J and Yang J 2009 J. Eur. Ceram. Soc. 29 1101

Dabbs D M, Yao N and Aksay I A 1999 J. Nanopart. Res. 1 127

Yoshida K, Hyuga H, Kondo N and Kita H 2010 Mater. Sci. Eng. B 173 66

Aksay I A, Dabbs D M and Sarikaya M 1991 J. Am. Ceram. Soc. 74 2343

Nurishi Y and Pask J A 1982 Ceram. Int. 8 57

Saruhan B, Albers W, Schneider H and Kaysser W A 1996 J. Eur. Ceram. Soc. 16 1075

Rana A P S, Aiko O and Pask J A 1982 Ceram. Int. 8 151

Rodrigo P D D and Boch P 1985 Int. J. High Technol. Ceram. 1 3

Boch P, Chartier T and Rodrigo P D D 1990 In: S Somiya, R F Davis and J A Pask (eds) Mullite and mullite matrix composites Ceramic Transactions vol 6 (Westerville, OH: American Ceramic Society) p 353

Tripathi H S and Banerjee G 1998 J. Eur. Ceram. Soc. 18 2081

Viswabaskaran V, Gnanam F D and Balasubramanian M 2003 J. Mater. Process. Technol. 142 275

Tripathi H S, Das S K, Mukherjee B, Ghosh A and Banerjee G 2001 Ceram. Int. 27 833

Tripathi H S, Das S K and Banerjee G 2000 Ceram. Int. 26 1

Lee W E and Rainforth W M 1994 Ceramic microstructures: property control by processing (London: Chapman & Hall) p 299

Viswabaskaran V, Gnanam F D and Balasubramanian M 2003 J. Mater. Sci. Lett. 22 663

Viswabaskaran V, Gnanam F D and Balasubramanian M 2004 Appl. Clay Sci. 25 29

Montanaro L, Esnouf C, Perrot C, Thollet G, Fantozzi G and Negro A 2000 J. Am. Ceram. Soc. 83 189

Montanaro L, Tulliani J M, Perrot C and Negro A 1997 J. Eur. Ceram. Soc. 17 1715

Ismail M G M U, Tsunatori H and Nakai S 1990 J. Mater. Sci. 25 2619

Sivakumar R, Jayaseelan D D, Nishikawa T, Honda S and Awaji H 2001 Ceram. Int. 27 537

Soutoa P M, Menezesb R R and Kiminami R H G A 2009 J. Mater. Process. Technol. 209 548

Wrust J C and Nelson J A 1972 J. Am. Ceram. Soc. 55 109

Heraiz M, Merrouche A and Saheb N 2006 Adv. Appl. Ceram.: Struct. Funct. Bioceram. 105 285

Acknowledgements

We thankfully acknowledge the support of Mr S Mukherjee and Mr S Chaterjee of Almatis, India, for the raw materials and the staff of Department of Ceramic Engineering, NIT, Rourkela, for different experiments during the work, especially for the phase analysis and microstructural study.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sarkar, R., Mallick, M. Formation and densification of mullite through solid-oxide reaction technique using commercial-grade raw materials. Bull Mater Sci 41, 31 (2018). https://doi.org/10.1007/s12034-017-1533-7

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-017-1533-7