Abstract

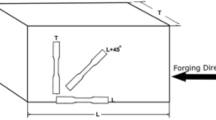

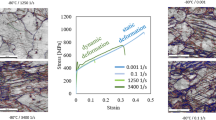

This paper presents some experimental investigations about the origins of the anisotropic behaviour in cyclic loadings of AA2017 aluminium alloy. In the first step, fatigue damage evolutions were quantified for controlled proportional cyclic loadings in axial and shear directions. In this stage, the aim was to confirm the anisotropic mechanical behaviour, which has recently been revealed. To this end, several models of fatigue damage quantification were used. After a comparative study between the obtained results we confirmed the anisotropic nature of the used material. In the second step, microstructural investigations were performed in order to understand the origins of the anisotropic mechanical behaviour. We used scanning electron microscopy to analyse phases and precipitates in the transversal and the longitudinal sections. It was deduced that the structure and the morphology of these entities are responsible for the anisotropic behaviour of the used aluminium alloy. Moreover, the results obtained using Kikushi diagrams, poles figure and inverse poles figures have also confirmed these conclusions. Indeed, these results have shown great differences in crystallographic texture of the material.

Similar content being viewed by others

References

Bois-Brochu A, Blais C, Goma F A T, Boselli J and Brochu M 2014 Mater. Sci. Eng. A 62 597

Immarigeon J P, Holt R T, Koul A K, Zhao L and Beddoes J C 1995 Mater. Charact. 35 41

May A, Belouchrani M A, Taharboucht S and Boudras A 2010 Proc. Eng. 2 1795

Williams J C and Starke E A Jr 2003 Acta Mater. 51 5775

May A, Belouchrani M A, Manaa A and Bouteghrine Y 2011 Proc. Eng. 10 798

Moy C K S, Weiss M, Xia J, Sha G, Ringer S P and Ranzi G 2012 Mater. Sci. Eng. A 48 552

Bouzaiene H, Rezgui M A, Ayadi M and Zghal A 2012 Trans. Nonferr. Met. Soc. 22 1064

Araújo D, Carpio F J, Méndez D, García A J, Villar M P, García R, Jiménez D and Rubio L 2003 Appl. Surf. Sci. 208 210

Carpio F J, Araújo D, Pacheco F J, Méndez D, García A J, Villar M P, García R, Jiménez D and Rubio L 2003 Appl. Surf. Sci. 209 194

Zhang L, Liu X S, Wang L S, Wu S H and Fang H Y 2012 Trans. Nonferr. Metal. Soc. 22 2777

Kluger K 2015 Int. J. Fatigue 22 80

Kluger K and Łagoda T 2014 Int. J. Fatigue 66 229

Taharboucht S, Aberkane A and May A 2016 Thesis p 62

Mayer H, Papakyriacou M, Pippan R and Stanzl-Tschegg S 2001 Mater. Sci. Eng. A 48 314

Kofto D G 1990 Strength Mater. 22 283

May A, Taleb L and Belouchrani M A 2013 Mater. Sci. Eng. A 123 571

Le V-D, Morel F, Bellett D, Saintier N and Osmond P 2016 Mater. Sci. Eng. A 426 649

Pineau A, Amine Benzerga A and Pardoen T 2016 Acta Mater. 107 508

Celentano D J and Chaboche J-L 2007 Int. J. Plast. 23 1739

Djebli A, Aid A, Bendouba M, Amrouche A, Benguediab M and Benseddiq N 2013 Int. J. Nonlin. Mech. 51 145

Chaboche J L 1987 Nucl. Eng. Des. 19 105

Chaboche J L 1989 Int. J. Plast. 5 247

Wang C, Wang X, Ding Z, Xu Y and Gao Z 2015 Int. J. Fatigue 11 78

Aid A, Amrouche A, Bouiadjra B B, Benguediab M and Mesmacque G 2011 Mater. Des. 32 183

Nouailhas D, Chaboche J L, Savalle S and Cailletaud G 1985 Int. J. Plast. 1 317

Walvekar A A, Leonard B D, Sadeghi F, Jalalahmadi B and Bolander N 2014 Tribol. Int. 79 183

Thionnet A, Chambon L and Renard J 2002 Int. J. Fatigue 24 147

Lukáš P, Jardin A, Leblond J-B, Berghezan D and Portigliatti M 2010 Proc. Eng. 2 1643

Szusta J and Seweryn A 2011 Int. J. Fatigue 33 255

Trebuňa P F, Sága M, Kopas P and Uhríčík M 2012 Proc. Eng. 48 599

Lemaitre J 1985 Comput. Meth. Appl. Mech. Eng. 51 31

Chak-yin T, Jianping F, Chi-pong T, Tai-chiu L, Luen-chow C and Bin R 2007 Acta Mech. Solida Sin. 20 57

Kim D, Dargush G F and Basaran C 2013 Eng. Struct. 52 608

Shen F, Hu W and Meng Q 2016 Int. J. Fatigue 90 125

Kauppila P, Kouhia R, Ojanperä J, Saksala T and Sorjonen T 2016 Proc. Struct. Integrity 2 887

Jiang M 1995 Eng. Fract. Mech. 52 971

Crooks R, Wang Z, Levit V I and Shenoy R N 1998 Mater. Sci. Eng. A 257 145

Al-Maharbi M, Karaman I, Beyerlein I J, Foley D, Hartwig K T, Kecskes L J and Mathaudhu S N 2011 Mater. Sci. Eng. A 528 7616

Khan A S and Baig M 2011 Int. J. Plast. 27 522

Li X, Al-Samman T and Gottstein G 2011 Mater. Des. 32 4385

Cho J -H, Jae Kim W and Gil Lee C 2014 Mater. Sci. Eng. A 597 314

Gilles G, Hammami W, Libertiaux V, Cazacu O, Yoon J H, Kuwabara T, Habraken A M and Duchêne L 2011 Int. J. Solids Struct. 48 1277

Joo M S, Suh D W, Bae J H, Sanchez Mouriño N, Petrov R, Kestens L A I and Bhadeshia H K D H 2012 Mater. Sci. Eng. A 556 601

Banumathy S, Mandal R K and Singh A K 2010 J. Alloys Compd. 26 500

Williams B W, Simha C H M, Abedrabbo N and Mayer R 2010 Int. J. Impact. Eng. 37 652

Brünig M 1995 Fin. Elem. Anal. Des. 20 155

Dillard T, Forest S and Lenny P 2006 Eur. J. Mech. A-Solid 25 526

Khadyko M, Dumoulin S, Børvik T and Hopperstad O S 2015 Comput. Struct. 15 60

Saï K, Taleb L and Cailletaud G 2012 Comput. Mater. Sci. 65 48

Dong C, Yang X, Shi D and Yu H 2014 Mater. Des. 55 966

Vanegas E, Mocellin K and Logé R 2011 Proc. Eng. 10 1208

Garmestani H, Kalidindi S R, Williams L, Fountain C and Lee E W 2002 Int. J. Plast. 18 1373

Wang Z-W, Yuan Y-B, Zheng R-X and Ameyama K 2014 Trans. Nonferr. Met. Soc. 24 2366

Papasidero J, Doquet V and Lepeer S 2014 Mater. Sci. Eng. A 610 203

Hajizadeh K, Tajally M, Emadoddin E and Borhani E 2014 J. Alloys Compd. 588 690

Zong C, Zhu G-H and Mao W-M 2013 J. Iron. Steel Res. Int. 20 66

Hales S J and Hafley R A 1998 Mater. Sci. Eng. A 257 153

Mizera J, Driver J H, Jezierska E and Kurzydłowski K J 1996 Mater. Sci. Eng. A 94 21

Khan S, Kintzel O and Mosler J 2012 Int. J. Fatigue 37 112

Henry D L 1955 Trans. Am. Soc. Mech. Eng. 77 913

Golos K and Ellyin F 1987 Theor. Appl. Fract. Mech. 7 169

Bui-Quoc T 1982 Exp. Mech. 22 180

Acknowledgements

The author acknowledges the French Team of Oxford Instrument for their grateful help in releasing the EBSD/EDS analyses using their best material resources.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

MAY, A. On the origins of the anisotropic mechanical behaviour of extruded AA2017 aluminium alloy. Bull Mater Sci 40, 395–406 (2017). https://doi.org/10.1007/s12034-017-1383-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-017-1383-3