Abstract

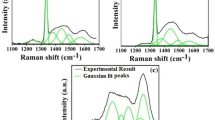

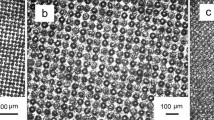

Diamond coatings were grown on SiO2/Si substrate under various process conditions by microwave plasma chemical vapour deposition (MPCVD) using CH4/H2 gas mixture. In this paper, we present a microstructural study to elucidate on the growth mechanism and evolution of defects, viz., strain, dislocations, stacking faults, twins and non-diamond impurities in diamond coatings grown under different process conditions. Transmission electron microscopy (TEM), X-ray diffraction (XRD) and Raman spectroscopy were used to characterize the diamond coatings. It has been shown that our new approach of prolonged substrate pre-treatment under hydrogen plasma yielded a new growth sequence that the SiO2 layer on the Si substrate was first reduced to yield Si layer of ∼150 nm thickness before diamond was allowed to grow under CH4–H2 plasma, created subsequently. It has also been shown that Si and O as impurity from the substrate hinders the initial diamond growth to yield non-diamond phases. It is being suggested that the crystal defects like twins, stacking faults, dislocations in the diamond grains and dislocations in the intermediate Si layer are generated due to the development of non-uniform stresses during diamond growth at high temperature.

Similar content being viewed by others

References

Coe S E and Sussmann R S 2000 Diam. Relat. Mater. 9 1726

Brown W D, Beera R A, Naseem H A and Malshe A P 1996 Surf. Coat. Technol. 86 698

Willander M, Friesel M, Wahab Q U and Straumal B 2006 J. Mater. Sci.: Mater. Electron. 17 1

Mallik A K, Shivashankar S A and Biswas S K 2009 Sadhana 34 811

Silva F J G, Fernandes A J S, Costa F M, Teixeira V, Baptista A P M and Pereira E 2003 Wear 255 846

Thumm M 2001 Diam. Relat. Mater. 10 1692

Brandon J R, Coe S E, Sussmann R S, Sakamoto K, Sporl R, Heidinger R and Hanks S 2001 Fusion Eng. Des. 53 553

Liu J M, Xia Y B, Wang L J, Su Q F, Zhao P, Xu R, Peng H Y and Shi W M 2006 Trans. Nonferrous Met. SOC China 16 s298

Sumant A V, Auciello O, Yuan H C, Ma Z, Carpick R W and Mancini D C 2009 Proc. SPIE 7318 731817–1

Nistor L, Landuyt J V and Ralchenko V 1999 Phys. Status Solidi (a) 174 5

Aleksandrov V D and Selskaya I V 2003 Inorg. Mater. 39 455

Yang J X, Duan X F, Lu F X, Li C M, Zuo T C and Wang F L 2005 Diam. Relat. Mater. 14 1583

Ralchenko V G, Pleuler E, Lu F X, Sovyk D N, Bolshakov A P, Guo S B, Tang W Z, Gontar I V, Khomich A A, Zavedeev E V and Konov V I 2012 Diam. Relat. Mater. 23 172

May P W 2000 Philos Trans. R. Soc. Lond. A 358 473

Butler J E and Sumant A V 2008 Chem. Vapour Depos. 14 145

Ralchenko V, Sychov I, Vlasov I, Vlasov A, Konov V, Khomich A and Voronina S 1999 Diam. Relat. Mater. 8 189

Delclos S, Dorignac D, Phillipp F, Silva F and Gicquel A 1998 Diam. Relat. Mater. 7 222

Delclos S, Dorignac D, Phillipp F, Silva F and Gicquel A 2000 Diam. Relat. Mater. 9 346

Nistor L C, Landuyt J V, Ralchenko V G, Obraztsova E D and Smolin A A 1997 Diam. Relat. Mater. 6 159

Yin L W, Zou Z D, Li M S, Sun D S, Liu Y X and Hao Z Y 2000 Diam. Relat. Mater. 9 2006

Wittorf D, Jager W, Dieker C, Floter A and Guttler H 2000 Diam. Relat. Mater. 9 1696

Waite M M and Shah S I 1992 Appl. Phys. Lett. 60 2344

Kato Y, Goto M, Sato R, Yamada K, Koga A, Teii K, Srey C and Tanaka S 2011 Surf. Coat. Technol. 206 990

Mallik A K, Pal K S, Dandapat N, Guha B K, Datta S and Basu D 2012 Diam. Relat. Mater. 30 53

Filik J 2005 Spectrosc. Europe 17 10

Lin T, Loh K P, Wee A T S, Shen Z X, Lin J, Lai C H, Gao Q J and Zhang T J 2000 Diam. Relat. Mater. 9 1703

Nistor L, Ralchenko V, Vlasov I, Khomich A, Khmelnitskii R, Potapov P and Landuyt J V 2001 Phys. Status Solidi (a) 186 207

Ajeian B, Beckey H D, Maas A and Nitschke U 1975 Appl. Phys. A: Mater. Sci. Process. 6 111

Comins J D, Daniel R D, Erasmus R M and Brookes E J 2000 Diam. Relat. Mater. 9 1115

Brookes C A 1979 The properties of diamond Field JE (Ed.) (London Academic Press) p 383

Lee S T, Lin Z and Jiang X 1999 Mater. Sci. Eng. R 25 123

Butler J E and Oleynik I 2008 Phil. Trans. R. Soc. A 366 295

Jiang X and Jia C L 1995 Appl. Phys. Lett. 679 1197

Jia C L, Urban K and Jiang X 1995 Phys. Rev. B 52 5164

Acknowledgements

We gratefully thank Council for Scientific and Industrial Research for financial support for carrying out the present work. We also like to thank the Director, Central Glass and Ceramic Research Institute, for the permission to publish this work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

PAL, K.S., BYSAKH, S., MALLIK, A.K. et al. Influence of growth conditions on microstructure and defects in diamond coatings grown by microwave plasma enhanced CVD. Bull Mater Sci 38, 717–724 (2015). https://doi.org/10.1007/s12034-015-0908-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-015-0908-x