Abstract

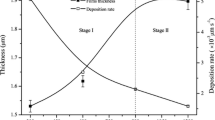

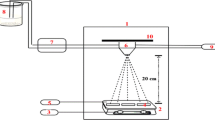

CuInSe2 thin films were prepared by one-step electrodeposition process using a simplified two-electrodes system. The films were deposited, during 5, 10, 15 and 20 min, from the deionized water solution consisting of CuCl2, InCl3 and SeO2 onto ITO-coated glass substrates. As-deposited films have been annealed under vacuum at 300 °C during 30 min. The structural, optical band gap and electrical resistivity of elaborated films were studied, respectively, using X-ray diffraction (XRD), Raman spectroscopy, UV spectrophotometer and four-point probe method. The micro structural parameters like lattice constants, crystallite size, dislocation density and strain have been evaluated. The XRD investigation proved that the film deposited at 20 min present CuInSe2 single phase in its chalcopyrite structure and with preferred orientation along (1 1 2) direction, whereas the films deposited at 5, 10 and 15 min show the CuInSe2 chalcopyrite structure with the In2Se3 as secondary phase. We have found that the formation mechanism of CuInSe2 depends on the In2Se3 phase. The optical band gap of the films is found to decrease from 1.17 to 1.04 eV with increase in deposition time. All films show Raman spectra with a dominant A1 mode at 174 cm−1, confirming the chalcopyrite crystalline quality of these films. The films exhibited a range of resistivity varying from 2.3 × 10−3 to 4.4 × 10−1 Ω cm.

Similar content being viewed by others

References

Chaure N B, Young J, Samantilleke A P and Dharmadasa I M 2004 Sol. Energy Mat. Sol. Cells 81 125

Chen H, Yu S M, Shin D W and Yoo J B 2010 Nanoscale Res. Lett. 5 217

Deepa K G, Jayakrishnan R, Vijayakumar K P, Sudha Kartha C and Ganesan V 2009 Solar Energy 83 964

Deepa K G, Vijayakumar K P and Sudhakartha C 2012 Mater. Sci. Semiconduct. Proc. 15 120

Dhanam M, Manoj P K and Prabhu R R 2005 J. Cryst. Growth 280 425

Fahoume M, Chraibi F, Aggour M and Ennaoui A 1998 Ann. Chim. Sci. Mater. 23 373

Faraday M 1834 Philos. Trans. R. Soc. 124 77

Guillemoles J F, Cowache P, Lusson A, Fezzaa K, Boisivon F, Vedel J and Lincot D 1996 J. Appl. Phys. 79 7293

Guillén C, Martinez M A and Herrero J 2000 Vacuum 58 594

Huang C J, Meen T H, Lai M Y and Chen W R 2004 Sol. Energy Mater. Sol. Cells 82 553

International Center for Diffraction Data, ICDD, PDF2 Database, file number 40-1487 for CuInSe2.

International Center for Diffraction Data, ICDD, PDF2 Database, file number 72-1469 for In2Se3.

Julien C and Eddrief M 1992 Mater. Sci. Eng. B13 247

Kavcar N, Carter M J and Hill R 1992 Sol. Energy Mat. Sol. Cells 27 13

Malssel L I and Glang R 1970 Handbook of thin film technology (New York: McGraw Hill Book Company)

Mellikov E et al 2008 Thin Solid Films 516 7125

Moharram A H, Hafiz M M and Salem A 2001 Appl. Surf. Sci. 172 61

Moorthy Babu S, Ennaoui A and Ch Lux-Steiner M 2005 J. Cryst. Growth 275 1241

Muller J, Nowoczin J and Schmitt H 2006 Thin Solid Films 496 364

Murali K R 1988 Thin Solid Films 167 19

Niki S, Suzuki R, Ishibashi S, Ohdaira T, Fons P J, Yamada A, Oyanagi H, Wada T, Kimura R and Nakada T 2001 Thin Solid Films 387 129

Pachori R D, Banerjee A and Chopra K L 1986 Bull. Mater. Sci. 8 291

Pal R, Chattopadhyay K K, Chaudhuri S and Pal A K 1994 Thin Solid Films 247 8

Parretta A, Addonizio M L, Agati A, Pellegrino M, Quercia L, Cardellini F, Kessler J and Schock H W 1993 Jpn. J. Appl. Phys. 32 80

Rincon C, Gonzalez J and Sanchez Perez G 1983 Solid State Commun. 48 1001

Shah N M, Ray J R, Patel K J, Kheraj V A, Desai M S, Panchal C J and Rehani B 2009 Thin Solid Films 517 3639

Sharma K C, Sharma R P and Garg C 1992 J. Phys. D: Appl. Phys. 24 1019

Tembhurkar Y D and Hirde J P 1994 Bull. Mater. Sci. 17 465

Urbach F 1953 Phys. Rev. 92 1324

Volobujeva O, Altosaar M, Raudoja J, Mellikov E, Grossberg M, Kaupmees L and Barvinschi P 2009 Sol. Energy Mat. Sol. Cells 93 11

Weast R C (ed.) 1980 CRC handbook of chemistry and physics (Boca Raton, FL: CRC)

Wellings J S, Samantilleke A P, Heavens S N, Warren P and Dharmadasa I M 2009 Sol. Energy Mat. Sol. Cells 93 1518

White F R, Clark A H and Graf M C 1979 J. Appl. Phys. 50 544

Zaretskaya E P, Gremenok V F, Riede V, Schmitz W, Bente K, Zalesski V B and Ermakov O V 2003 J. Phys. Chem. Solids 64 1989

Zouaoui A, Lachab M, Hidalgo M L, Chaffa A, Llinares C and Kesri N 1999 Thin Solid Films 339 10

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Meglali, O., Attaf, N., Bouraiou, A. et al. One-step electrodeposition process of CuInSe2: Deposition time effect. Bull Mater Sci 37, 1535–1542 (2014). https://doi.org/10.1007/s12034-014-0108-0

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12034-014-0108-0