Abstract

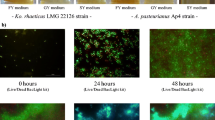

It is imperative that promising bacterial cellulose-producing bacteria mainly belongs to genera Acetobacter (acid-producing bacteria). In order to screen cellulose-producing Acetobacter, the isolated cultures from vinegar/rotten fruits were inoculated in Hestrin-Schramm (HS) medium containing ethanol and CaCO3. After the desired incubation, the positive cultures form a zone, which is observed around the bacterial growth, resulted from the solubilization of CaCO3 by acetic acid produced from the oxidation of ethanol during fermentation. However, in this method, the clarity of the solubilized zone is not very sharp and distinct. In the present, investigation, an improved method for screening, of the microorganisms producing acetic acid has been developed. In this method, methyl red (MR) is incorporated as a pH indicator in HS medium containing ethanol and CaCO3. Plates containing MR at alkaline pH are yellow and turn dark red at acidic pH. Thus, a distinctive, clear zone is formed around bacterial colonies producing acetic acid and is easy to differentiate between acid producers and non-producers. The present method is more rapid, accurate, and sensitive and can be successfully be used for the detection of acetic acid-producing bacteria particularly for the screening of potent cellulose producer Acetobacter sp.

Similar content being viewed by others

References

Tabuchi, M. (2007). Nanobiotech versus synthetic nanotech ? Nat Biotechnol, 25(4), 389–390.

Rouabhia, M., Asselin, J., Tazi, N., Messaddeq, Y., Levinson, D., & Zhang, Z. (2014). Production of biocompatible and antimicrobial bacterial cellulose polymers functionalized by RGDC grafting groups and gentamicin. ACS Appl Mater Interfaces, 6(3), 1439–1446.

Park, C. H., Lee, C. S., Kim, Y. J., Jang, J. H., Suh, J. Y., & Park, J. W. (2010). Improved pre-osteoblast response and mechanical compatibility of ultrafine-grained Ti–13Nb–13Zr alloy. Clin Oral Implants Res, 22(7), 735–742.

Jonas, R., & Farah, L. F. (1998). Production and Application of Microbial Cellulose. Polym Degrad Stab, 59(1–3), 101–106.

Vandamme, E. J., Baets, S. D., vanbaelen, A., Joris, K., & Wulf, P. D. (1998). Improved production of bacterial cellulose and its application potential. Polym Degrad Stab, 59(1-3), 93–99.

Lin, S. P., Calver, I. L., Catchmark, J. M., Liu, J. R., Demirci, A., & Cheng, K. C. (2013). Biosynthesis, production and applications of bacterial cellulose. Cellulose, 20(5), 2191–2219.

Fontana, J. D., Franco, V. C., Souza, S. J. D., Lyra, I. N., & Souza, A. M. D. (1991). Nature of plant stimulators in the production of Acetobacter xylinum ("tea fungus") biofilm used in skin therapy. Biotechnol Appl Biochem, 28(1), 341–351.

Hong, F., Zhu, Y. X., Yang, G., & Yang, X. X. (2011). Wheat straw acid hydrolysate potential cost-effective feedstock for production of bacterial cellulose. J Chem Technol Biotechnol, 86(5), 675–680.

Karahan, A. G., Akoğlu, A., Çakır, I., Kart, A., Çakmakçı, M. L., Uygun, A., & Göktepe, F. (2011). Some properties of bacterial cellulose produced by new native strain Gluconacetobacter sp. A06O2 obtained from Turkish vinegar. J Appl Polym Sci, 121(3), 1823–1831.

Zeng, X., Small, D. P., & Wan, W. (2011). Statistical optimization of culture conditions for bacterial cellulose production by Acetobacter xylinum BPR 2001 from maple syrup. Carbohydr Polym, 85(3), 506–513.

Rastogi, A., & Banerjee, R. (2019). Production and characterization of cellulose from Leifsonia sp. Process Biochem, 85, 35–42.

Cannon, R. E., Anderson, S., & M. (1991). Biogenesis of bacterial cellulose. Crit Rev Microbiol, 17(6), 435–447.

Hungund, B. S., & Gupta, S. G. (2010). Production of bacterial cellulose from Enterobacter amnigenus GH-1 isolated from rotten apple. World J Microbiol Biotechnol, 26(10), 1823–1828.

Römling, U. (2002). Molecular biology of cellulose production in bacteria. Res Microbiol, 153(4), 205–212.

Saied, H. E., Basta, A. H., & Gobran, R. H. (2004). Research progress in friendly environmental technology for the production of cellulose products bacterial cellulose and its application. Polym-Plast Technol Eng, 43(3), 797–820.

Chawla, P. R., Bajaj, I. B., Survase, S. A., & Singhal, R. S. (2009). Fermentative production of microbial cellulose. Food Technol Biotechnol, 47(2), 107–124.

Hungund, B. S., & Gupta, S. G. (2010). Production of bacterial cellulose from Enterobacter amnigenusGH-1 isolated from rotten apple. World J Microbiol Biotechnol, 26(10), 1823.

Yin, N., Chen, S., Li, Z., Ouyang, Y., Hu, W., Tang, L., Zhang, W., Zhou, B., Yang, J., Xu, Q., & Wang, H. (2012). Porous bacterial cellulose prepared by a facile surfactant-assisted foaming method in azodicarbonamide - NaOH aqueous solution. Mater Lett, 81(15), 131–134.

Klemm, D., Schumann, D., Udhardt, U., & Marsch, S. (2001). Bacterial synthesized cellulose - artificial blood vessels for microsurgery. Prog Polym Sci, 26(9), 1561–1603.

Brown, R. M. J. (2004). Cellulose structure and biosynthesis: What is in store for the 21st century? J Polym Sci Part A Polym Chem, 42(3), 487–495.

Zhong, C., Li, F., Liu, M., Yang, X. N., Zhu, H. X., Jia, Y. Y., Jia, S. R., & Piergiovanni, L. (2014). Revealing differences in metabolic flux distributions between a mutant strain and its parent strain Gluconacetobacter xylinus CGMCC 2955. PLoS One, 9(6), e98772. https://doi.org/10.1371/journal.pone.0098772.

Joseph, G., Rowe, G. E., Margaritis, A., & Wan, W. (2003). Effects of polyacrylamide-co-acrylic acid on cellulose production by Acetobacter xylinum. J Chem Technol Biotechnol, 78(9), 964–970.

Park, J. K., Jung, J. Y., & Park, Y. H. (2003). Cellulose production by Gluconacetobacter hansenii in a medium containing ethanol. Biotechnol Lett, 25(24), 2055–2059.

Jozala, A. F., Pertile, R. A. N., Santos, C. A. D., Ebinuma, V. D. C. S., Seckler, M. M., Gama, F. M., & Pessoa, A. (2014). Bacterial cellulose production by Gluconacetobacter xylinus by employing alternative culture media. Appl Microbiol Biotechnol, 99(3), 1181–1190.

Kongruang, S. (2008). Bacterial cellulose production by Acetobacter xylinum strains from agricultural waste products. Biotechnol Appl Biochem, 148, 245–256.

Acknowledgements

The authors are thankful to SERB-DST-India EMR/2016/002786 for funding. M.B. and S.S. thank CSIR-IIIM, Jammu for providing the facilities. IIIM Publication No. CSIR- IIIM /IPR/ 0098. I would like to confirm that this article is original and not communicated elsewhere.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, M., Tanoj, N. & Saran, S. A Modified, Efficient and Sensitive pH Indicator Dye Method for the Screening of Acid-Producing Acetobacter Strains Having Potential Application in Bio-Cellulose Production. Appl Biochem Biotechnol 191, 631–636 (2020). https://doi.org/10.1007/s12010-019-03211-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-019-03211-x