Abstract

Softwood bark contains a large amounts of extractives—i.e., soluble lipophilic (such as resin acids) and hydrophilic components (phenolic compounds, stilbenes). The effects of the partial removal of water-soluble extractives before acid-catalyzed steam pretreatment on enzymatic digestibility were assessed for two softwood barks—Norway spruce and Scots pine. A simple hot water extraction step removed more than half of the water-soluble extractives from the barks, which improved the enzymatic digestibility of both steam-pretreated materials. This effect was more pronounced for the spruce than the pine bark, as evidenced by the 30 and 11% glucose yield improvement, respectively, in the enzymatic digestibility. Furthermore, analysis of the chemical composition showed that the acid-insoluble lignin content of the pretreated materials decreased when water-soluble extractives were removed prior to steam pretreatment. This can be explained by a decreased formation of water-insoluble “pseudo-lignin” from water-soluble bark phenolics during the acid-catalyzed pretreatment, which otherwise results in distorted lignin analysis and may also contribute to the impaired enzymatic digestibility of the barks. Thus, this study advocates the removal of extractives as the first step in the processing of bark or bark-rich materials in a sugar platform biorefinery.

Similar content being viewed by others

Explore related subjects

Find the latest articles, discoveries, and news in related topics.Avoid common mistakes on your manuscript.

Introduction

Large amounts of bark are produced and are readily available worldwide at sawmills and pulp mills, as bark is removed from the logs during the manufacturing process. In Sweden, 80% of the total standing volume in productive forest lands comprises Norway spruce (Picea abies) and Scots pine (Pinus sylvestris) species, and an estimated 7.7 million m3 of bark is produced annually, based on industrial wood consumption [42]. Today, most bark is combusted at mill sites or district heating plants to produce heat and electricity, although upgrading bark constituents to value-added fuels and chemicals could be beneficial economically and environmentally [30].

Although many of the constituents in wood also occur in bark, the chemical composition and structure of bark differ significantly from those of wood [35]. For example, bark has a lower cellulose and hemicellulose content but typically contains higher amounts of ash, non-cellulosic sugars, and extractives. One of the most disparate compositional characteristic of bark is its large amounts of extractives—i.e., soluble lipophilic (such as resin acids) and hydrophilic components (phenolic compounds, stilbenes) [35]. Extractives from Scots pine and Norway spruce barks have recently been characterized by Bianchi et al. [4, 5], Co et al. [8], Kemppainen et al. [15], Krogell et al. [17], Normand et al. [26], and Vernarecová et al. [48]. Extractives have both traditional (e.g., tannins in the leather industry) as well as a range of new uses—for instance, to produce adhesives, resins, and foams [9, 21]. Certain extractives also have pharmaceutical applications [22, 29].

The emergence of second-generation biofuels has increased the interest in assessing the suitability of softwood barks as a feedstock for renewable fuel production [6, 31, 32, 43]. Unfortunately, the structural complexity and heterogeneity of bark render it more difficult to utilize than wood fractions. Softwoods are generally considered the most recalcitrant type of lignocellulosic feedstock for the production of monomeric sugars by pretreatment and enzymatic hydrolysis [11, 19], but the breakdown of softwood barks to generate monomeric sugars from the carbohydrate part has proved to be even more challenging [10, 52].

The lower holocellulose content of bark inevitably lowers theoretical sugar/ethanol yields; furthermore, extractives can potentially have adverse effects on the biochemical conversion of pretreated material. It has previously been shown that elevated amounts of soluble extractives can impair the hydrolytic performance of the enzymes [16, 50], whereas Kemppainen et al. [14] hypothesized that the condensation reactions of bark extractives during acid-catalyzed steam pretreatment, rendering the otherwise water-soluble extractives insoluble and altering the structure of the solid fraction, results in impaired enzymatic hydrolysis. Thus, more severe pretreatment of spruce bark—through the use of an acid catalyst or higher temperature—resulted in a material that elicited a lower hydrolysis rate and sugar yield when subjected to enzymatic hydrolysis. This finding has negative implications in cases where debarking proves to be technically difficult or uneconomic, but severe pretreatment would also be required to provide reasonable sugar yields (e.g., forest harvest residues). The removal of extractives has mainly been investigated with the idea to valorize the extracted compounds [15, 21], but it also generates a holocellulose-enriched residual and might also improve the enzymatic digestibility [14]. However, the effect of hot water extraction followed by acid-catalyzed steam pretreatment was not examined.

In this study, the effects of hot water extraction of softwood barks on subsequent acid-catalyzed steam pretreatment and enzymatic hydrolysis were assessed. The composition of the non-extracted and the hot water-extracted barks of Norway spruce and Scots pine, as well as the steam-pretreated materials, was analyzed. The enzymatic digestibilities of the barks were determined after steam pretreatment and acid-catalyzed steam pretreatment, with or without prior hot water extraction, to examine the possibility of utilizing water extraction to enhance sugar recovery. The results have implications for bark biorefineries and the pretreatment of softwood forest harvest residues—an abundant raw material that is expected to contain bark.

Methods

Raw Materials

The bark of Scots pine, P. sylvestris, was obtained from a tree that was sampled from long-term field trials in the Svartbergets experimental forests, Unit of Field-Based Research, Swedish University of Agricultural Sciences (SLU). The bark fraction was separated, chipped to approximately 100 × 10 mm, and stored in plastic bags at −20 °C. The bark of Norway spruce, P. abies, was kindly provided by a local sawmill (ATA Timber Widtskövle AB, Everöd, Sweden). The pine and spruce barks were chipped further using a knife mill (Retsch GmbH, Haan, Germany) and sieved to obtain a 2- to 10-mm fraction. Pine bark had a dry matter content of 44 wt%, whereas that of spruce bark was 33 wt%. The raw materials were stored in plastic buckets at 4 °C until use.

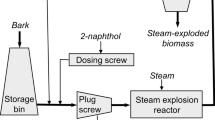

Hot Water Extraction

Water extraction of the raw materials was performed in a 60-L stirred tank in 2 consecutive steps: a 2-h cold water extraction at 6% consistency, followed by a 3-h hot water extraction after the primary extracts were drained and replaced with hot tap water (decreasing the consistency to 5.1%). The conditions of hot water extraction were chosen to facilitate effective removal of water-soluble extractives [15] but to avoid intense hemicellulose removal [17], as well as to provide comparability with previous results on hot water-extracted spruce bark [14, 15, 21]. The temperature was maintained at 25 °C during the cold water extraction, whereas after being heated for 1 h, it was kept at 80 °C for 2 h in the hot water extraction step. The stirring rate (200 rpm) was the same in both steps. More thorough water extraction was performed by repeating the hot water extraction step three times. After extraction, the extracts were drained, and the extracted barks were collected. The extracted materials were filter-pressed at a maximum pressure of 5 bar using a hydraulic press (HP5M, Fischer Maschinenfabrik, Neuss, Germany) to adjust the DM content to 30–35 wt% prior to steam pretreatment.

Steam Pretreatment

Prior to steam pretreatment, each batch, with a total dry weight of 600 g, was impregnated with gaseous SO2 (2.5 wt%, based on the moisture content of raw material) in tightly sealed plastic bags for 20 min at room temperature. Excess SO2 was vented before the steam pretreatment by leaving the plastic bags open for 30 min. Steam pretreatment was performed in batches at 210 °C for 5 min in a 10-L reactor, per Palmqvist et al. [28]. Steam pretreatments were also conducted without SO2 impregnation at 190 or 210 °C for 5 min. The pretreated slurries were stored at 4 °C prior to subsequent analysis and experiments.

Enzymatic Hydrolysis

Enzymatic hydrolysis of the pretreated slurry was performed in 2-L Labfors bioreactors (Infors AG, Bottmingen, Switzerland) with a working weight of 1 kg. A water-insoluble solids (WIS) load of 10% mass fraction and Cellic CTec3 enzyme cocktail, kindly provided by Novozymes A/S (Bagsvaerd, Denmark), at a load of 5% mass fraction of WIS, were applied, corresponding approximately to 9 FPU/g WIS. The hydrolysis experiments proceeded for 96 h at 45 °C, with a stirring rate of 400 rpm, at pH 5, maintained with 2.5 M NaOH solution. Samples from the hydrolysis liquid were separated in a centrifuge (Galaxy 16 DH, VWR International, Radnor, PA, USA), Germany) in 2-mL Eppendorf tubes at 16,000xg for 8 min. The supernatant was passed through 0.2-μm filters (GVS Filter Technology, Morecambe, UK) and stored at −20 °C. The enzymatic hydrolysis experiments were performed in duplicate.

Analyses

The total solids content of biomass materials and the total dissolved solids content of liquid samples were determined per the National Renewable Energy Laboratory (NREL) [36]. The WIS content of pretreated slurries was measured using the no-wash method of Weiss et al. [46]. The extractives, structural carbohydrates, lignin, and ash contents of the solid fractions and the composition of the liquid fractions were determined per NREL methods [37,38,39,40].

Sugars, organic acids, and other degradation products were quantified by high-performance liquid chromatography (HPLC) on a Shimadzu LC 20AD HPLC system that was equipped with a Shimadzu RID 10A refractive index detector (Shimadzu Corporation, Kyoto, Japan). Samples for sugar analysis were pH-adjusted to 5, if necessary, with CaCO3 and centrifuged in 2-mL Eppendorf tubes (16,000×g for 5 min). All samples were passed through 0.2-μm filters (GVS Filter Technology) and stored at −20 °C until analysis. Sugars were analyzed on a Bio-Rad Aminex HPX-87P column with a De-Ashing Bio-Rad micro-guard column (Bio-Rad Laboratories, Hercules, CA, USA) at 85 °C using degassed deionized water as the eluent at a flow rate of 0.5 ml/min. Organic acids and other degradation products were analyzed on a Bio-Rad Aminex HPX-87H chromatography column with a Cation-H Bio-Rad micro-guard column at 50 °C, with a mobile phase of 5 mM sulfuric acid at a flow rate of 0.5 mL/min.

Yield Calculation

The glucose yield in the enzymatic hydrolysis experiments was calculated, based on the total available glucose in the liquid and the solid fraction of the steam-pretreated materials per the following equation. The nomenclature for the equations is presented in Table 1.

The degree of enzymatic hydrolysis was calculated as:

Results and Discussion

The digestibility of pretreated softwood barks has been reported to be rather low [10, 51]. One factor that has been suggested to contribute to this is the condensation of water-soluble phenolic compounds during acid-catalyzed steam pretreatment. These compounds remain in the fiber fraction—they are in fact analyzed as acid-insoluble lignin—and can reduce the accessibility to cellulose during enzymatic hydrolysis [14]. As a result, less severe pretreatment (i.e., without acid catalyst) was found to be beneficial for spruce bark. Alternatively, water-soluble extractives can be removed before pretreatment in order to avoid detrimental condensation reactions and enable pretreatment conditions that are sufficiently severe to break down softwood bark. In this study, this step was performed by hot water extraction of softwood barks, after which the extracted materials were subjected to acid-catalyzed steam pretreatment and enzymatic hydrolysis.

Removal of Water-Soluble Extractives

Hot water extraction was used to remove extractives of spruce and pine barks, and raw material analyses were performed before and after the hot water extraction to determine the total amount removed (Table 2). Spruce bark had a higher total extractives content (24.0%) than pine bark (19.4%), the primary difference between which was the content of water-soluble extractives—the ethanol-soluble extractives content of spruce bark was slightly higher than that of pine bark.

Extractives contents between studies should be compared with caution, even for the same species, because they also depend on age, felling season, storage conditions [4, 15], and extraction method [7]. A wide range of extractives content has consequently been reported for spruce and pine barks, ranging from 4.5 to 28.2% for spruce bark [10, 14, 24] versus 3.5 to 19.3% for pine bark [24, 27, 45]. The results of this study are consistent with the extractives content for spruce and pine barks using similar extraction schemes. For spruce bark, Frankó et al. [10] reported 28.2% of total (water- and ethanol-soluble) extractives, whereas Valentín et al. [45] obtained a 13.7% water-soluble extractives content for pine bark.

A major compositional difference between spruce and pine barks that this study noted, apart from the extractives content, was the considerably higher lignin content of pine bark. The total lignin content was 40.9% for pine bark, in contrast to 29.9% for spruce bark. These results are comparable with the reported values for pine (33.7 and 44.9%) and spruce barks (27.9%; 32.8 and 33.8%) [10, 14, 24, 45]. Spruce bark had higher glucan content than pine bark, whereas the contents of the other main carbohydrates were similar between spruce and pine barks. Accordingly, the total content of carbohydrates was higher in spruce versus pine bark. The proportion of C6 carbohydrates to total carbohydrates was nearly the same in both softwood barks (80 and 75%). Similar carbohydrate contents were also reported for spruce and pine barks by Miranda et al. [24]. The ash content was also comparable with the range in the literature [10, 14, 24, 33, 47].

The water extraction scheme removed more than half of the water-soluble extractives from spruce (57%) and pine bark (51%) (Table 2). Consequently, the levels of other bark constituents, such as carbohydrates, lignin, and ash, increased in hot water-extracted barks compared with the non-extracted raw materials. A variety of research approaches and analytical methods have been used to characterize hydrophilic extractives of softwood barks [4, 5, 15, 17, 21]. The extraction yields vary with different factors (e.g., extraction temperature, time, solid loading, particle size, etc.) but water extracts of softwood barks are mainly composed of condensed tannins, stilbene glucosides, and mono- and polysaccharides (e.g., pectic polysaccharides). The chemical composition of water extracts from spruce and pine barks, among other European softwood species, has been analyzed by Bianchi et al. [5]. Although the ratio of condensed tannins relative to total phenolic compounds was high in the water extracts for spruce and pine barks, Bianchi et al. [5] found that the proportion of total phenolic compounds was significantly lower in water extracts from pine bark versus spruce bark (13.0 and 34.1%, respectively).

More thorough water extraction, performed by repeating the hot water extraction 3 times (3X-HWE), removed an additional 15% of the water-soluble extractives from spruce bark, but complete removal of extractives was not achieved. Even though hot water extraction can efficiently remove tannins from bark, condensed tannins cannot be completely extracted due to covalent bonds between the condensed tannins and the cellulose matrix [9, 13].

Steam Pretreatment

Steam pretreatment with SO2 as the acid catalyst is considered a suitable pretreatment method for recalcitrant lignocellulosic feedstocks, such as softwood [12], and was chosen in the current study for the barks. The composition of the water-insoluble solids fractions of the steam-pretreated materials were determined (Table 3). As a result of its lower initial glucan content, the glucan content of steam-pretreated pine barks—non-extracted and hot water-extracted—was considerably lower than in spruce barks. Steam pretreatment removed most of the hemicelluloses in all steam-pretreated materials, but sugars that originated from the hemicellulose, primarily xylose and mannose, were still detected in the solid fraction of the pretreated slurries. No significant difference in holocellulose content was observed between non-extracted and hot water-extracted barks pretreated under the same conditions.

In contrast, the acid-insoluble lignin (AIL) content of the water-insoluble fractions was higher in steam-pretreated barks that were not hot water-extracted, regardless of species (Table 3), although the AIL content was originally lower in the non-extracted raw materials than in hot water-extracted barks (Table 2). The total lignin recovery over steam pretreatment was 116 and 112% for non-extracted spruce and pine barks, respectively, compared with 101 and 107% for the hot water-extracted spruce and pine barks. This difference was most likely due to larger formation of “pseudo-lignin” in the steam pretreatment of non-extracted barks. The lowest total lignin recovery over steam pretreatment (94%) was obtained with 3X-HWE spruce bark. The apparent AIL content of the pretreated materials decreased as more water-soluble phenolic compounds were removed from the barks by hot water extraction prior to steam pretreatment, supporting the hypothesis that water-soluble bark phenolics are rendered insoluble in acid-catalyzed treatments and are subsequently analyzed as insoluble lignin residue [7, 10, 14, 44]. Further, the AIL content was considerably lower for the barks—both non-extracted and hot water-extracted—that were steam-pretreated without the addition of an acid catalyst (i.e., under milder conditions). In the absence of an acid catalyst, the extent of degradation of hemicellulosic sugars during steam pretreatment is lower, which also results in a lower formation of lignin-like compounds (“pseudo-lignin”) [34].

The composition of liquid fractions that were obtained from the steam-pretreated materials (Table 4) did not differ significantly between the non-extracted and hot water-extracted barks, regardless of species. The concentrations of total sugars (expressed in monomeric form) were slightly lower in the liquid fraction of pretreated pine barks than in the corresponding spruce barks; however, the ratios of monomeric and oligomeric sugars were the same for all steam-pretreated materials that were subjected to the same pretreatment conditions—5 to 10% of all dissolved sugars were in oligomeric form after steam pretreatment at 210 °C for 5 min with 2.5% SO2. Omitting the acid catalyst in the pretreatment step significantly increased oligomeric sugar levels (55 to 60% of all dissolved sugars). Decreasing the severity of the pretreatment by performing the steam pretreatment at 190 °C shifted the ratio further, with nearly 70% of all dissolved sugars in oligomeric form. Moreover, as a consequence of milder pretreatment conditions, the concentrations of dissolved sugars were slightly lower in the liquid fractions of materials pretreated without the addition of acid catalyst.

The levels of degradation products (1.4–2.0 g/L acetic acid and 0.3–1.1 g/L HMF and furfural) were similar for hot water-extracted and non-extracted barks pretreated under the same conditions, consistent with earlier studies that found that softwood barks generate less inhibitors during acid-catalyzed steam pretreatment than bark-free softwoods (2–3 g/L acetic acid, 2–6 g/L HMF, and ~ 1.5 g/L furfural) [10, 43]. Steam pretreatment without the addition of an acid catalyst (lower severity) resulted in even lower concentrations of inhibitory compounds (less than 0.3 g/L HMF or furfural) in the liquid fraction of steam-pretreated spruce barks, because the amount of degradation products that are generated during steam pretreatment is a function of the severity of the pretreatment.

Effects on Enzymatic Digestibility

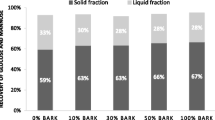

The glucan content of spruce barks was, as discussed, higher than that of pine barks (Table 3), as was the glucose concentration after enzymatic hydrolysis of spruce barks (Fig. 1). However, the final glucose yields were higher for pine barks than the corresponding spruce barks. The proportion of glucose that was released during steam pretreatment was similar between softwood barks (14.4 and 16.6% for spruce and pine barks, respectively); thus, pine bark showed better digestibility based on the difference in the degree of hydrolysis (32.8 and 43.4% for spruce and pine barks, respectively) (Fig. 2).

Concentration profiles of glucose during enzymatic hydrolysis and final glucose yields. Enzymatic hydrolysis of spruce (diamonds) and pine barks (triangles), non-extracted (open symbols), and hot water-extracted (HWE) (filled symbols), steam-pretreated under the same conditions (210 °C, 5 min, 2.5% SO2) at 10% WIS loading, 45 °C, pH 5 for 96 h using Cellic CTec3 enzyme cocktail at a dose of 5 wt% based on WIS. The error bars show the lowest and highest concentrations. Total glucose yields expressed as percent of the theoretical value, based on all available glucose in the pretreated materials

Degree of hydrolysis after 96 h of enzymatic hydrolysis of steam-pretreated pine and spruce barks. Enzymatic hydrolysis of steam-pretreated (210 °C, 5 min, 2.5% SO2) pine and spruce barks, non-extracted or hot water-extracted (HWE), at 10 wt% WIS loading, 45 °C, pH 5 for 96 h using Cellic CTec3 enzyme cocktail at a dose of 5 wt% based on WIS. The degree of hydrolysis was calculated based on the sum of oligomeric glucose in the liquid fraction and glucose available in the solid fraction of the steam-pretreated materials. The error bars show the lowest and highest values

In general, softwoods are recalcitrant to biochemical conversion and require high-severity pretreatment conditions [12], high enzyme doses [2], and possibly an additional delignification step [19] to provide a reasonable yield of monomeric sugars. Overcoming the inherent recalcitrance of the bark fractions of spruce and pine has been more challenging for these types of wood fractions [10, 27]. These results are consistent with the glucose yields that were obtained in this study (Fig. 1). For instance, using twice the amount of the same enzyme cocktail, but at the same solids loading as in the current study, the glucose yield was 53% for spruce bark that was pretreated under the same conditions [10]. Higher glucose yields—up to 80%—were reported by Kemppainen et al. [14] for spruce bark but at a significantly lower solids loading (1% dry matter) and an enzyme loading of 25 FPU/g solid Celluclast 1.5 L.

Soluble compounds generated during the pretreatment of softwoods are known to impair microbial fermentation [1] and also the hydrolytic performance of the enzymes. The inhibitory effects of monomeric [49] and oligomeric [20] sugar components and non-sugar components, such as degradation products of sugars, lignin, and extractives [3, 16, 18, 50], have been previously examined. However, decreasing enzymatic digestibility has previously been observed both on whole slurry and on washed fibers with increasing proportions of bark in SO2-catalyzed steam-pretreated spruce bark and wood mixtures [10], suggesting that the soluble inhibitory compounds that are liberated during steam pretreatment of bark are not the main cause of the significantly lower enzymatic digestibility of bark versus the wood fraction.

One of the goals of this work was to determine whether enzymatic digestibility can be improved by removing extractives prior to acid-catalyzed pretreatment. Regardless of the species, hot water extraction positively affected the digestibility of the pretreated materials (Fig. 2). However, this favorable effect was more pronounced for spruce bark versus pine bark. The degree of hydrolysis rose from 32.8 to 42.8% and from 43.4 to 48.0% for spruce and pine barks, respectively, from the hot water extraction prior to steam pretreatment. Although barks still remain challenging substrates for enzymatic hydrolysis, this increase in enzymatic digestibility of steam-pretreated spruce and pine barks corresponds to 30 and 11% glucose yield improvement, respectively. The hot water extraction step was more efficient for spruce bark—i.e., a slightly higher proportion of water-soluble extractives was removed. However, because spruce bark originally contained more water-soluble extractives than pine bark, the hot water-extracted barks harbored approximately the same fraction of water-soluble extractives prior to steam pretreatment. This result suggests that there are differences in the chemical structure of the water-soluble extractives fraction of the barks of these softwood species, contributing to the disparate enzymatic digestibilities. Thus, the total amount of remaining water-soluble extractives is not the sole determinant.

Because the effect of hot water extraction on enzymatic digestibility was more prominent with spruce bark and also because its holocellulose content makes it more relevant as a sugar platform than pine bark, additional experiments were performed with spruce bark, including a more extensive hot water extraction (i.e., repeated three times) and steam pretreatments without the addition of SO2 (Fig. 3). The steam pretreatment of non-extracted spruce bark at 210 °C for 5 min with 2.5% SO2 catalyst, which has been shown to be effective for the pretreatment of spruce wood chips [41], resulted in the lowest yield of glucose that was released during enzymatic hydrolysis. Steam pretreatment without the acid catalyst and a decrease in temperature (lowering the severity of the steam pretreatment) did not significantly improve this yield. These results somewhat contradict a previous study, in which more severe steam pretreatment decreased the rate and yield of hydrolysis [14]. This trend, however, was not seen at higher enzyme doses in that study, and there was no significant difference in the final glucose yields of enzymatic hydrolysis observed after 48 h, regardless of the use of acid catalyst in the pretreatment step. Although the enzyme dose in our experiments was comparable with the low dose in the aforementioned study, the newer, more effective commercial enzyme cocktail that was used in our study might explain the improved, similar enzymatic digestibility, regardless of the addition of acid catalyst or the decrease in temperature in the steam pretreatment.

Glucose yield after enzymatic hydrolysis of steam-pretreated spruce barks. Enzymatic hydrolysis of spruce barks, non-extracted or hot water-extracted (HWE), steam-pretreated under various conditions at 10% WIS loading, 45 °C, pH 5 for 96 h using Cellic CTec3 enzyme cocktail at a dose of 5 wt% based on WIS. The filled bars show the glucose released during steam pretreatment (STEX) step, while the unfilled bars represent the glucose released during the enzymatic hydrolysis (EH) step. The error bars show the lowest and highest values

However, with regard to total glucose yields (Fig. 3), it is apparent that the use of an acid catalyst during the steam pretreatment was highly beneficial when the monomeric glucose that was released during the steam pretreatment was included. Total glucose yield of 31.9% was obtained after enzymatic hydrolysis of non-extracted spruce bark that was steam-pretreated for 5 min without acid catalyst at 210 °C, whereas addition of the acid catalyst increased the total glucose yield to 43.6%. When comparing hydrolysis data with the results of Kemppainen et al. [14], it should be noted that the acid catalyst and the impregnation method differed in the former study (soaking in 0.5% sulfuric acid solution), which might also have contributed to the difference in total glucose yields. Nevertheless, the total amount of monomeric glucose that was liberated from non-extracted spruce bark by steam pretreatment and enzymatic hydrolysis was considerably higher when acid catalyst was used in the pretreatment step in the present study.

A detailed analysis of interactions between extractives that have been isolated from various wood fractions and cellulose surfaces has previously shown that deposition of the phenolic extractives fraction from pine wood on microcrystalline cellulose negatively affected the glucose release during enzymatic hydrolysis [23]. The partial removal of water-soluble extractives by hot water extraction before the steam pretreatment step improved the enzymatic digestibility of spruce bark. The degree of enzymatic hydrolysis and total glucose yields were greater with hot water-extracted spruce bark in all cases, but the positive effect was significantly better when the steam pretreatment was performed with an acid catalyst (32 and 9% improvement in the degree of hydrolysis with and without an acid catalyst in the pretreatment step, respectively). This result is consistent with the explanation that water-soluble extractives undergo detrimental changes during steam pretreatment that impair the subsequent enzymatic hydrolysis, especially when steam pretreatment is performed in the presence of acid catalyst. Despite the improvements in the enzymatic digestibility of both barks by hot water extraction prior to pretreatment, the total glucose yields remained lower than previous results on the stem wood fraction of spruce [10, 25]. Additionally, a more thorough hot water extraction step, resulting in the removal of an additional 15% of water-soluble extractives before the acid-catalyzed steam pretreatment, did not result in further improvements in the degree of hydrolysis or total glucose yield (Fig. 3). Clearly, bark remains a challenging substrate for enzymatic hydrolysis.

Conclusions

The use of acid catalyst during steam pretreatment was found to be beneficial in reducing the recalcitrance of softwood barks from spruce and pine. However, the formation of water-insoluble “pseudo-lignin” from water-soluble bark extractives during acid-catalyzed steam pretreatment resulted in distorted lignin analysis of the pretreated materials and potentially contributed to an impaired enzymatic digestibility. The acid-insoluble lignin content of the pretreated materials decreased as more water-soluble phenolic compounds were removed from the barks by hot water extraction prior to steam pretreatment, whereas no significant difference in holocellulose content was observed between non-extracted and hot water-extracted barks pretreated under the same conditions. Partial removal of water-soluble extractives by hot water extraction improved the enzymatic digestibility of steam-pretreated softwood barks. The obtained increase in enzymatic digestibility of steam-pretreated spruce and pine barks after extraction corresponded to 30 and 11% glucose yield improvement, respectively.

Abbreviations

- AIL:

-

acid-insoluble lignin

- ASL:

-

acid-soluble lignin

- DM:

-

dry matter

- EH:

-

enzymatic hydrolysis

- FPU:

-

filter paper unit

- HPLC:

-

high-performance liquid chromatography

- HWE:

-

hot water extracted

- NREL:

-

National Renewable Energy Laboratory

- STEX:

-

steam explosion

- WIS:

-

water-insoluble solids

References

Almeida, J., Modig, T., Petersson, A., Hahn-Hagerdal, B., Liden, G., & Gorwa-Grauslund, M. (2007). Increased tolerance and conversion of inhibitors in lignocellulosic hydrolysates by Saccharomyces cerevisiae. Journal of Chemical Technology and Biotechnology, 82, 340–349.

Arantes, V., & Saddler, J. (2011). Cellulose accessibility limits the effectiveness of minimum cellulase loading on the efficient hydrolysis of pretreated lignocellulosic substrates. Biotechnology for Biofuels, 4, 3.

Berlin, A., Balakshin, M., Gilkes, N., Kadla, J., Maximenko, V., Kubo, S., & Saddler, J. (2006). Inhibition of cellulase, xylanase and β-glucosidase activities by softwood lignin preparations. Journal of Biotechnology, 125, 198–209.

Bianchi, S., Koch, G., Janzon, R., Mayer, I., Saake, B., & Pichelin, F. (2016). Hot water extraction of Norway spruce (Picea abies [Karst.]) bark: analyses of the influence of bark aging and process parameters on the extract composition. Holzforschung, 70(7), 619–631.

Bianchi, S., Kroslakova, I., Janzon, R., Mayer, I., Saake, B., & Pichelin, F. (2015). Characterization of condensed tannins and carbohydrates in hot water bark extracts of European softwood species. Phytochemistry, 120, 53–61.

Boussaid, A., Cai, Y., Robinson, J., Gregg, D. J., Nguyen, Q., & Saddler, J. N. (2001). Sugar recovery and fermentability of hemicellulose hydrolysates from steam-exploded softwoods containing bark. Biotechnology Progress, 17, 887–892.

Burkhardt, S., Kumar, L., Chandra, R., & Saddler, J. (2013). How effective are traditional methods of compositional analysis in providing an accurate material balance for a range of softwood derived residues? Biotechnology for Biofuels, 6, 90.

Co, M., Fagerlund, A., Engman, L., Sunnerheim, K., Sjöberg, P. J. R., & Turner, C. (2012). Extraction of antioxidants from spruce (Picea abies) bark using eco-friendly solvents. Phytochemical Analysis, 23, 1–11.

Feng, S., Cheng, S., Yuan, Z., Leitch, M., & Xu, C. (2013). Valorization of bark for chemicals and materials: a review. Renewable and Sustainable Energy Reviews, 26, 560–578.

Frankó, B., Galbe, M., & Wallberg, O. (2015). Influence of bark on fuel ethanol production from steam-pretreated spruce. Biotechnology for Biofuels, 8, 15.

Galbe, M., & Zacchi, G. (2002). A review of the production of ethanol from softwood. Applied Biochemistry and Biotechnology, 59, 618–628.

Galbe, M., & Zacchi, G. (2012). Pretreatment: the key to efficient utilization of lignocellulosic materials. Biomass and Bioenergy, 46, 70–78.

Ishimaru, K., Nonaka, G.-I., & Nishioka, I. (1987). Flavan-3-ol and procyanidin glycosides from Quercus miyagii. Phytochemistry, 26, 1167–1170.

Kemppainen, K., Inkinen, J., Uusitalo, J., Nakari-Setälä, T., & Siika-aho, M. (2012). Hot water extraction and steam explosion as pretreatments for ethanol production from spruce bark. Bioresource Technology, 117, 131–139.

Kemppainen, K., Siika-aho, M., Pattathil, S., Giovando, S., & Kruus, K. (2014). Spruce bark as an industrial source of condensed tannins and non-cellulosic sugars. Industrial Crops and Products, 52, 158–168.

Kim, Y., Ximenes, E., Mosier, N. S., & Ladisch, M. R. (2011). Soluble inhibitors/deactivators of cellulase enzymes from lignocellulosic biomass. Enzyme Microb Tech, 48, 408–415.

Krogell, J., Holmbom, B., Pranovich, A., Hemming, J., & Willför, S. (2012). Extraction and chemical characterization of Norway spruce inner and outer bark. Nordic Pulp & Paper Research Journal, 27, 6–17.

Kumar, L., Arantes, V., Chandra, R., & Saddler, J. (2012). The lignin present in steam pretreated softwood binds enzymes and limits cellulose accessibility. Bioresource Technology, 103, 201–208.

Kumar, L., Chandra, R., Chung, P. A., & Saddler, J. (2010). Can the same steam pretreatment conditions be used for most softwoods to achieve good, enzymatic hydrolysis and sugar yields? Bioresource Technology, 101, 7827–7833.

Kumar, R., & Wyman, C. E. (2014). Strong cellulase inhibition by Mannan polysaccharides in cellulose conversion to sugars. Biotechnology and bioengineering, 111(7), 1341–1353.

Lacoste, C., Čop, M., Kemppainen, K., Giovando, S., Pizzi, A., Laborie, M.-P., Sernek, M., & Celzard, A. (2015). Biobased foams from condensed tannin extracts from Norway spruce (Picea abies) bark. Industrial Crops and Products, 73, 144–153.

Le Normand, M., Mélida, H., Holmbom, B., Michaelsen, T. E., Inngjerdingen, M., Bulone, V., Paulsen, B. S., & Ek, M. (2014). Hot-water extracts from the inner bark of Norway spruce with immunomodulating activities. Carbohydrate Polymers, 101, 699–704.

Leskinen, T., Salas, C., Kelley, S. S., & Argyropoulos, D. S. (2015). Wood extractives promote cellulase activity on cellulosic substrates. Biomacromolecules, 16, 3226–3234.

Miranda, I., Gominho, J., Mirra, I., & Pereira, H. (2012). Chemical characterization of barks from Picea abies and Pinus sylvestris after fractioning into different particle sizes. Industrial Crops and Products, 36, 395–400.

Monavari, S., Galbe, M., & Zacchi, G. (2009). Impact of impregnation time and chip size on sugar yield in pretreatment of softwood for ethanol production. Bioresource Technology, 100, 6312–6316.

Normand, M. L., Edlund, U., Holmbom, B., & Ek, M. (2012). Hot-water extraction and characterization of spruce bark non-cellulosic polysaccharides. Nordic Pulp & Paper Research Journal, 27, 18–23.

Normark, M., Winestrand, S., Lestander, T. A., & Jönsson, L. J. (2014). Analysis, pretreatment and enzymatic saccharification of different fractions of Scots pine. BMC Biotechnology, 14, 1–12.

Palmqvist, E., Hahn-Hägerdal, B., Galbe, M., Larsson, M., Stenberg, K., Szengyel, Z., Tengborg, C., & Zacchi, G. (1996). Design and operation of a bench-scale process development unit for the production of ethanol from lignocellulosics. Bioresource Technology, 58, 171–179.

Pietarinen, S. P., Willför, S. M., Ahotupa, M. O., Hemming, J. E., & Holmbom, B. R. (2006). Knotwood and bark extracts: strong antioxidants from waste materials. Journal of Wood Science, 52, 436–444.

Ragauskas, A. J., Williams, C. K., Davison, B. H., Britovsek, G., Cairney, J., Eckert, C. A., Frederick, W. J., Hallett, J. P., Leak, D. J., Liotta, C. L., Mielenz, J. R., Murphy, R., Templer, R., & Tschaplinski, T. (2006). The path forward for biofuels and biomaterials. Science, 311, 484–489.

Robinson, J., Keating, J., Boussaid, A., Mansfield, S., & Saddler, J. (2002). The influence of bark on the fermentation of Douglas-fir whitewood pre-hydrolysates. Applied Microbiology and Biotechnology, 59, 443–448.

Robinson, J., Keating, J. D., Mansfield, S. D., & Saddler, J. N. (2003). The fermentability of concentrated softwood-derived hemicellulose fractions with and without supplemental cellulose hydrolysates. Enzyme Microb Tech, 33, 757–765.

Saarela, K. E., Harju, L., Rajander, J., Lill, J. O., Heselius, S. J., Lindroos, A., & Mattsson, K. (2005). Elemental analyses of pine bark and wood in an environmental study. Science of the Total Environment, 343, 231–241.

Sannigrahi, P., Kim, D., Jung, S., & Ragauskas, A. (2011). Pseudo-lignin and pretreatment chemistry. Energy & Environmental Science, 4, 1306–1310.

Sjostrom, E. (2013). Wood chemistry: fundamentals and applications. Elsevier.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D. (2008). Determination of Total Solids in Biomass and Total Dissolved Solids in Liquid Process Samples: Laboratory Analytical Procedure (LAP). NREL/TP-510-42621. http://www.nrel.gov/docs/gen/fy08/42621.pdf.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D. (2008). Determination of Ash in Biomass: Laboratory Analytical Procedure (LAP). NREL/TP-510-42622. http://www.nrel.gov/docs/gen/fy08/42622.pdf.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., (2008). Determination of Sugars, Byproducts, and Degradation Products in Liquid Fraction Process Samples: Laboratory Analytical Procedure (LAP). NREL/TP-510-42623. http://www.nrel.gov/docs/gen/fy08/42623.pdf.

Sluiter, A., Hames, B., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D., Crocker, D. (2012). Determination of Structural Carbohydrates and Lignin in Biomass: Laboratory Analytical Procedure (LAP) (Revised August 2012). Issue Date: 4/25/2008. NREL/TP-510-42618. http://www.nrel.gov/docs/gen/fy13/42618.pdf.

Sluiter, A., Ruiz, R., Scarlata, C., Sluiter, J., Templeton, D. (2008) Determination of Extractives in Biomass: Laboratory Analytical Procedure (LAP). NREL/TP-510-42619. http://www.nrel.gov/docs/gen/fy08/42619.pdf.

Stenberg, K., Tengborg, C., Galbe, M., & Zacchi, G. (1998). Optimisation of steam pretreatment of SO2-impregnated mixed softwoods for ethanol production. Journal of Chemical Technology & Biotechnology, 71, 299–308.

Swedish Forest Agency. (2014). Swedish statistical yearbook of forestry of 2014. Official Statistics of Sweden. https://www.skogsstyrelsen.se/globalassets/statistik/historisk-statistik/skogsstatistisk-arsbok-2010-2014/skogsstatistisk-arsbok-2014.pdf.

Taherzadeh, M. J., Eklund, R., Gustafsson, L., Niklasson, C., & Lidén, G. (1997). Characterization and fermentation of dilute-acid hydrolyzates from wood. Industrial & Engineering Chemistry Research, 36, 4659–4665.

Torget, R., Himmel, M. E., & Grohmann, K. (1991). Dilute sulfuric acid pretreatment of hardwood bark. Bioresource Technology, 35, 239–246.

Valentín, L., Kluczek-Turpeinen, B., Willför, S., Hemming, J., Hatakka, A., Steffen, K., & Tuomela, M. (2010). Scots pine (Pinus sylvestris) bark composition and degradation by fungi: Potential substrate for bioremediation. Bioresource Technology, 101, 2203–2209.

Weiss, N., Stickel, J., Wolfe, J., & Nguyen, Q. (2010). A simplified method for the measurement of insoluble solids in pretreated biomass slurries. Applied Biochemistry and Biotechnology, 162, 975–987.

Werkelin, J., Skrifvars, B.-J., & Hupa, M. (2005). Ash-forming elements in four Scandinavian wood species. Part 1: summer harvest. Biomass and Bioenergy, 29, 451–466.

Vernarecová, M., Ház, A., Dubinyová, L., & Sladková, A. (2015). Extraction of phenolic and lipophilic compounds from spruce (Picea abies) bark using accelerated solvent extraction by ethanol. Wood research, 60, 583–590.

Xiao, Z., Zhang, X., Gregg, D. J., & Saddler, J. N. (2004). In M. Finkelstein, J. D. McMillan, B. H. Davison, & B. Evans (Eds.), Proceedings of the Twenty-Fifth Symposium on Biotechnology for Fuels and Chemicals held May 4–7, 2003, in Breckenridge, CO (pp. 1115–1126). Totowa: Humana Press.

Ximenes, E., Kim, Y., Mosier, N., Dien, B., & Ladisch, M. (2011). Deactivation of cellulases by phenols. Enzyme Microb Tech, 48, 54–60.

Yamamoto, M., Niskanen, T., Iakovlev, M., Ojamo, H., & van Heiningen, A. (2014). The effect of bark on sulfur dioxide–ethanol–water fractionation and enzymatic hydrolysis of forest biomass. Bioresource Technology, 167, 390–397.

Zhang, C., Zhu, J. Y., Gleisner, R., & Sessions, J. (2012). Fractionation of forest residues of Douglas-fir for fermentable sugar production by SPORL pretreatment. Bioenergy Research, 5, 978–988.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Funding

The authors gratefully acknowledge the Swedish Energy Agency, Energimyndigheten, for financial support (project number: 41255-1).

Conflict of Interests

The authors declare that they have no conflict of interest.

Electronic supplementary material

ESM 1

(PDF 87 kb)

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Frankó, B., Carlqvist, K., Galbe, M. et al. Removal of Water-Soluble Extractives Improves the Enzymatic Digestibility of Steam-Pretreated Softwood Barks. Appl Biochem Biotechnol 184, 599–615 (2018). https://doi.org/10.1007/s12010-017-2577-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-017-2577-2