Abstract

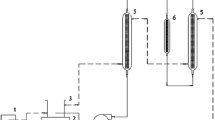

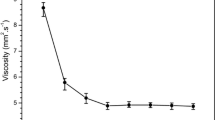

A semi-pilot continuous process (SPCP) for enzymatic biodiesel synthesis utilizing near-critical carbon dioxide (NcCO2) as the reaction medium was developed with the aim of reducing the reaction time and alleviating the catalyst inhibition by methanol. Biodiesel synthesis was evaluated in both lab-scale and semi-pilot scale reactors (batch and continuous reactors). In a SPCP, the highest conversion (∼99.9 %) in four and a half hours was observed when three-step substrate (methanol) addition (molar ratio [oil/methanol] = 1:1.3) was used and the reaction mixture containing enzyme (Lipozyme TL IM, 20 wt.% of oil) was continuously mixed (agitation speed = 300 rpm) at 30 °C and 100 bar in a CO2 environment. The biodiesel produced from canola oil conformed to the fuel standard (EU) even without additional downstream processing, other than glycerol separation and drying.

Similar content being viewed by others

References

Chen, J. W., & Wu, W. T. (2003). Regeneration of immobilized Candida antarctica lipase for transesterification. Journal of Bioscience and Bioengineering, 95, 466–469.

Lee, M., Lee, J., Lee, D., Cho, J., Kim, S., & Park, C. (2011). Improvement of enzymatic biodiesel production by controlled substrate feeding using silica gel in solvent free system. Enzyme and Microbial Technology, 49, 402–406.

Seong, P. J., Jeon, B. W., Lee, M., Cho, D. H., Kim, D. K., Jung, K. S., et al. (2011). Enzymatic coproduction of biodiesel and glycerol carbonate from soybean oil and dimethyl carbonate. Enzyme and Microbial Technology, 48, 505–509.

Go, A., Ko, J. W., Lee, S. J., Kim, S. W., Han, S. O., Lee, J., et al. (2012). Process design and evaluation of value-added chemicals production from biomass. Biotechnology and Bioprocess Engineering, 17, 1055–1061.

Fukuda, H., Kondo, A., & Noda, H. (2001). Biodiesel fuel production by transesterification of oils. Journal of Bioscience and Bioengineering, 92, 405–416.

Nelson, L. A., Foglia, T. A., & Marmer, W. N. (1996). Lipase-catalyzed production of biodiesel. Journal of the American Oil Chemists' Society, 73, 1191–1195.

Shimada, Y., Watanabe, Y., Sugihara, A., & Tominaga, Y. (2002). Enzymatic alcoholysis for biodiesel fuel production and application of the reaction to oil processing. Journal of Molecular Catalysis B: Enzymatic, 76, 133–142.

Köse, Ö., Tuter, M., & Aksov, H. A. (2002). Immobilized Candida antarctica lipase catalyzed alcoholysis of cotton seed oil in a solvent-free medium. Bioresource Technology, 82, 125–129.

Aucoin, M. G., & Legge, R. L. (2001). Effects of supercritical CO2 exposure and depressurization on immobilized lipase activity. Biotechnology Letters, 23, 1863–1870.

Lozano, P., Avellaneda, A., Pascual, R., & Iborra, J. L. (1996). Stability of immobilized α-chymotrypsin in supercritical carbon dioxide. Biotechnology Letters, 18, 1345–1350.

Overmeyer, A., Schrader, L. S., Kasche, V., & Brunner, G. (1999). Lipase-catalysed kinetic resolution of racemates at temperatures from 40 degrees C to 160 degrees C in supercritical CO2. Biotechnology Letters, 21, 65–69.

Nagesha, G. K., Manohar, B., & Udaya, S. K. (2004). Enzymatic esterification of free fatty acids of hydrolyzed soy deodorizer distillate in supercritical carbon dioxide. Journal of Supercritical Fluids, 32, 137–145.

Lee, M., Park, C., Cho, J., Lee, J., Lee, D., & Kim, S. (2010). Enzymatic biodiesel synthesis from canola oil in liquid carbon dioxide. Korean Society for Biotechnology and Bioengineering Journal, 25, 337–343.

Sovova, H., Zarevucka, M., Vacek, M., & Stransky, K. (2001). Solubility of two vegetable oils in supercritical CO2. Journal of Supercritical Fluids, 20, 15–28.

Ozkal, S. G., Yener, M. E., & Bayindirli, L. (2006). The solubility of apricot kernel oil in supercritical carbon dioxide. Journal of Food and Science and Technology, 41, 399–404.

Lee, M., Lee, D., Cho, J. K., Cho, J., Han, J., Park, C., et al. (2012). Improved high-pressure enzymatic biodiesel batch synthesis in near-critical carbon dioxide. Bioprocess and Biosystems Engineering, 35, 105–113.

Dossat, V., Combes, D., & Marty, A. (1999). Continuous enzymatic transesterification of high oleic sunflower oil in a packed bed reactor: influence of the glycerol production. Enzyme and Microbial Technology, 25, 194–200.

Shimada, Y., Watanabe, Y., Samukawa, T., Sugihara, A., Noda, H., Fukuda, H., et al. (1999). Conversion of vegetable oil to biodiesel using immobilized Candida antarctica lipase. Journal of the American Oil Chemists' Society, 76, 789–793.

Noureddini, H., & Harmeier, S. E. (1998). Enzymatic glycerolysis of soybean oil. Journal of the American Oil Chemists' Society, 75, 1359–1365.

Xu, Y., Du, W., Liu, D., & Zeng, J. (2003). A novel enzymatic route for biodiesel production from renewable oils in a solvent-free medium. Biotechnology Letters, 235, 1239–1241.

Talukder, M. R., Puah, S. M., Wu, J. C., Choi, J. W., & Chow, Y. (2006). Lipase-catalyzed methanolysis of palm oil in presence and absence of organic solvent. Biocatalysis and Biotransformation, 24, 257–262.

Torres, C., Lin, B., & Hill, C. G. (2002). Lipase-catalyzed glycerolysis of an oil rich in eicosapentaenoic lipase. Biotechnology Letters, 24, 667–673.

Lee, J. H., Kwon, C. H., Kwon, J. W., Park, C., Tae, B., & Kim, S. W. (2009). Biodiesel production from various oils under supercritical fluid condition by Candida antarctica Lipase B using a stepwise reaction method. Applied Biochemistry and Biotechnology, 156, 24–34.

Du, W., Xu, Y., & Liu, D. (2003). Lipase-catalysed transesterification of soya bean oil for biodiesel production during continuous batch operation. Biotechnology and Applied Biochemistry, 38, 103–106.

Lee, M., Chen, W., & Chou, C. (1999). Optimization and kinetic analysis of cholesterol oxidase production by Rhodococcus equi No. 23 in submerged cultures. Enzyme and Microbial Technology, 25, 598–604.

Xiaohu, F., Rachel, B., & Greg, A. (2009). Preparation and characterization of biodiesel produced from recycled canola oil. The Open Fuels and Energy Science Journal, 2, 113–118.

Acknowledgments

This work was funded by the Industrial Strategic Technology Development Program (project number: 10028375) of the Ministry of Knowledge Economy (MKE), Korea and by the Basic Research Program of the Korea Institute of Industrial Technology (KITECH). This research was also supported by the Research Grant from Kwangwoon University in 2013 and 2013 Postdoctoral Fellowship Program (Dr. M. Lee) of National Academy of Agricultural Science, Rural Development Administration, Republic of Korea. The semi-pilot continuous NcCO2 reactor was provided by Hanil Corporation, Korea.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Highlights

- We succeeded in the scale-up of enzymatic biodiesel synthesis in a semi-pilot continuous process (SPCP) with near-critical carbon dioxide (NcCO2).

- High biodiesel conversion (99.9 %) was obtained in SPCP under optimized conditions.

- The biodiesel conversion of the SPCP was about 90 % after 20 cycles of reuse.

Rights and permissions

About this article

Cite this article

Lee, M., Lee, D., Cho, J. et al. Enzymatic Biodiesel Synthesis in Semi-Pilot Continuous Process in Near-Critical Carbon Dioxide. Appl Biochem Biotechnol 171, 1118–1127 (2013). https://doi.org/10.1007/s12010-013-0189-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-013-0189-z