Abstract

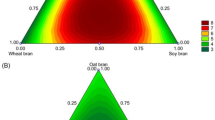

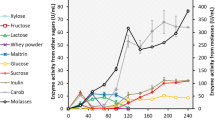

An exoinulinase has been isolated, purified and characterised from a commercially available broth of Aspergillus ficuum. The enzyme was purified 4.2-fold in a 21% yield with a specific activity of 12,300 U mg−1(protein) after dialysis, ammonium sulphate fractionation and Sephacryl S-200 size exclusion and ion exchange chromatography. The molecular weight of this enzyme was estimated to be 63 kDa by SDS-PAGE. It exhibited a pH and temperature optima of 5.4 and 50 °C respectively and under such conditions the enzyme remained stable with 96% and 63.8% residual activity after incubation for 12 h and 72 h respectively. The respective K m and V max values were 4.75 mM and 833.3 μmol min−1 ml−1, respectively. Response surface methodological statistical analysis was evaluated for the maximal production of fructose from the hydrolysis of pure commercial chicory inulin. Incubation of the dialyzed crude exoinulinase (100 U/ml, 48 h, 50 °C, 150% inulin, pH 5.0) produced the highest amount of fructose (106.4 mg/ml) under static batch conditions. The purified exoinulinase was evaluated for fructose production and the highest amount (98 mg/ml) was produced after 12 h incubation at 50 °C, 150% inulin pH 5.0. The use of a crude exoinulinase preparation is economically desirable and the industrial production of fructose from inulin hydrolysis is biotechnologically feasible.

Similar content being viewed by others

References

Rocha, J. R., Catana, R., Ferreira, B. S., Cabral, J. M. S., & Fernandes, P. (2006). Design and characterisation of an enzyme system for inulin hydrolysis. Food Chemistry, 95, 77–82. doi:10.1016/j.foodchem.2004.12.020.

Gill, P. K., Manhas, R. K., & Singh, P. (2006). Hydrolysis of inulin by immobilized thermostable extracellular exoinulinase from Aspergillus fumigatus. Journal of Food Engineering, 76, 369–375. doi:10.1016/j.jfoodeng.2005.05.052.

Diaz, E. G., Catana, R., Ferreira, B. S., Luque, S., Fernandes, P., & Cabral, J. M. S. (2006). Towards the development of a membrane reactor for enzymatic inulin hydrolysis. Journal of Membrane Science, 273, 152–158. doi:10.1016/j.memsci.2005.12.005.

Tomotani, E. J., & Vitolo, M. (2007). Production of high-fructose syrup using immobilized invertase in a membrane reactor. Journal of Food Engineering, 80, 662–667. doi:10.1016/j.jfoodeng.2006.07.002.

Nagem, R. A. P., Rojas, A. L., Golubev, A. M., Korneeva, A. S., Eneyskaya, E. V., Kulminskaya, A. A., et al. (2004). Crystal structure of exo-inulinase from Aspergillus awamori: The enzyme fold and structural determinants of substrate recognition. Journal of Molecular Biology, 344, 471–480. doi:10.1016/j.jmb.2004.09.024.

Bas, D., & Boyaci, I. H. (2007a). Modeling and optimization I: Usability of response surface methodology. Journal of Food Engineering, 78, 836–845. doi:10.1016/j.jfoodeng.2005.11.024.

Bas, D., & Boyaci, I. H. (2007b). Modeling and optimization II: Comparison of estimation capabilities of surface response methodology with artificial neural networks in biochemical reaction. Journal of Food Engineering, 78, 846–854. doi:10.1016/j.jfoodeng.2005.11.025.

Paseephol, T., Small, D., & Sherkat, F. (2007). Process optimization for fractionating Jerusalem artichoke fructans with ethanol using response surface methodology. Food Chemistry, 104, 73–80. doi:10.1016/j.foodchem.2006.10.078.

Laemmli, U. K. (1970). Cleavage of structural proteins during the assembly of the head of bacteriophage T4. Nature, 227, 680–685. doi:10.1038/227680a0.

Bollag, D. M., Rozycki, M. D., & Edelstein, S. J. (1996). Protein methods (2nd ed.). New York: Wiley-Liss. ISBN 0471118370.

Jing, W., Zhengyu, J., Bo, J., & Xueming, X. (2003). Separation and identification of Exo- and Endoinulinase from Aspergillus ficuum. Current Microbiology, 47, 109–112. doi:10.1007/s00284-002-3917-0.

Miller, G. L. (1959). Use of Dinitrosalicylic acid reagent for determination of reducing sugar. Analytical Chemistry, 31, 426–428. doi:10.1021/ac60147a030.

Moriyama, S., & Ohta, K. (2007). Functional characterisation and evolutionary implication of the internal 157-amino-Acid sequence of an exoinulinase from Penicillium sp. strain TN-88. Journal of Bioscience and Bioengineering, 103(4), 293–297. doi:10.1263/jbb.103.293.

Cornish-Bowden, A. (2004). Fundamentals of enzyme kinetics (3rd ed.). London: Portland.

Bradford, M. M. (1976). A rapid and sensitive method for the quantification of microgram quantities of protein utilizing the principle of protein dye binding. Analytical Biochemistry, 72, 248–254. doi:10.1016/0003-2697(76)90527-3.

Box, G. E. P., & Wilson, K. B. (1951). On the experimental attainment of optimum conditions. Journal of the Royal Statistical Society: Series B, 13(1), 1–45.

Bruins, M. E., Strubel, M., van Lieshout, J. F. T., Janssen, A. E. M., & Boom, R. M. (2003). Oligosaccharide synthesis by the hyperthermostable β-glucosidase from Pyrococcus furiosus: Kinetics and modeling. Enzyme and Microbial Technology, 33, 3–11. doi:10.1016/S0141-0229(03)00096-6.

Vandamme, E. J., & Derycke, D. G. (1983). Microbial inulinases: Fermentation process, properties and applications. Advances in Applied Microbiology, 29, 139–176. doi:10.1016/S0065-2164(08)70356-3.

Zhang, L., Zhao, C., Ohta, W. Y., & Wang, Y. (2005). Inhibition of glucose on an exoinulinase from Kluyveromyces marxianus expressed in Pichia pastoris. Process Biochemistry, 40, 1541–1545. doi:10.1016/j.procbio.2004.01.057.

Zhang, L., Zhao, C., Zhu, D., Ohta, Y., & Wang, Y. (2004). Purification and characterization of inulinase from Aspergillus niger AF10 expressed in Pichia pastoris. Protein Expression and Purification, 35, 272–275. doi:10.1016/j.pep.2004.02.015.

Sheng, J., Chi, Z., Li, J., Gao, L., & Gong, F. (2007). Inulinase production by the marine yeast Cryptococcus aureus G7a and inulin hydrolysis by the crude inulinase. Process Biochemistry, 42, 805–811. doi:10.1016/j.procbio.2007.01.016.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mutanda, T., Wilhelmi, B. & Whiteley, C.G. Controlled Production of Fructose by an Exoinulinase from Aspergillus Ficuum . Appl Biochem Biotechnol 159, 65–77 (2009). https://doi.org/10.1007/s12010-008-8479-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8479-6