Abstract

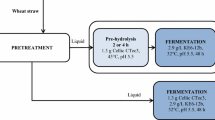

The present work presents an alternative approach to ethanol production from sweet sorghum: without detoxification, acid-impregnated fresh sweet sorghum stem which contains soluble (glucose and sucrose) and insoluble carbohydrates (cellulose and hemicellulose) was steam pretreated under mild temperature of 100 °C. Simultaneous saccharification and fermentation experiments were performed on the pretreated slurries using Saccharomyces cerevisiae. Experimentally, ground fresh sweet sorghum stem was combined with H2SO3 at dosages of 0.25, 0.50, and 0.75 g/g dry matter (DM) and steam pretreated by varying the residence time (60, 120, or 240 min). According to enzymatic hydrolysis results and ethanol yields, H2SO3 was a powerful and mild acid for improving enzymatic digestibility of sorghum stem. At a solid loading of 10% (w/v) and acid dosage of 0.25 g/g DM H2SO3 at 100 °C for 120 min, 44.5 g/L ethanol was obtained after 48 ± 4 h of simultaneous saccharification and fermentation. This corresponded to an overall ethanol yield of 110% of the theoretical one, based on the soluble carbohydrates in the fresh sweet sorghum stem. The concentrations of hydroxymethylfurfural and furfural of the sulfurous acid pretreated samples were below 0.4 g/L. Ethanol would not inhibit the cellulase activity, at least under the concentration of 34 g/L.

Similar content being viewed by others

References

FAO (2002). Sweet sorghum in China, In: World food summit, five years later. Agriculture Department, Food and Agriculture Organization of the United Nations (FAO).

Gnansounou, E., Dauriat, A., & Wyman, C. E. (2005). Bioresource Technology, 96, 985–1002. doi:10.1016/j.biortech.2004.09.015.

Bryan, W. L. (1990). Enzyme and Microbial Technology, 12, 437–442. doi:10.1016/0141-0229(90)90054-T.

Mamma, D., Koullas, D., Fountoukidis, G., Kekos, D., Macris, B. J., & Koukios, E. (1995). Process Biochemistry, 31(4), 377–381. doi:10.1016/0032-9592(95)00075-5.

Liu, R. H., & Shen, F. (2007). Bioresource Technology, in press.

Teixeira, L. C., Linden, J. C., & Schroeder, H. A. (1999). Renewable Energy, 16, 1070–1073.

Christakopoulos, P., Li, L. W., Kekos, D., & Macris, B. J. (1993). Bioresource Technology, 45, 89–92. doi:10.1016/0960-8524(93)90095-S.

Moiser, N., Wyman, C., Dale, B., Elander, R., Lee, Y. Y., Holtzapple, M., et al. (2005). Bioresource Technology, 96, 673–686. doi:10.1016/j.biortech.2004.06.025.

Gamez, S., Cabriales, J. J. G., Ramirez, J. A., Garrote, G., & Vazquez, M. (2006). Journal of Food Engineering, 74, 78–88. doi:10.1016/j.jfoodeng.2005.02.005.

Schell, D. J., Farmer, J., Newman, M., & McMillan, J. D. (2003). Applied Biochemistry and Biotechnology, 105, 69–85. doi:10.1385/ABAB:105:1-3:69.

Torget, R., Walter, P., Himmel, M., & Grohmann, K. (1991). Applied Biochemistry and Biotechnology, 28–29, 75–86. doi:10.1007/BF02922590.

Bernfeld, P. (1959). Methods in Enzymology, 2, 27–29.

Bertolini, M. C., Erlandes, J. R., & Laluse, C. (1991). Biotechnology and Bioengineering, 13, 197–202.

Ghose, T. K. (1987). Pure and Applied Chemistry, 59, 257–268. doi:10.1351/pac198759020257.

Holtzapple, M. T. (1993). Cellilose. In R. Macrae, R. K. Robinson, & M. J. Sadler (Eds.), Encyclopedia of food science, food technology, and nutrion (pp. 758–767). London: Academic Press.

Weimer, P. J., & Weston, W. M. (1985). Biotechnology and Bioengineering, 27, 1540–1547. doi:10.1002/bit.260271104.

Converse, A. O. (1993). Substrate factors limiting enzymatic hydrolysis. In J. N. Saddler (Ed.), Bioconversion of Forest and Agricultural Plant Residues, Chapter 4. Oxford: C.A.B. International.

Palmqvist, E., & Hahn, H. B. (2000). Bioresource Technology, 74, 17–24. doi:10.1016/S0960-8524(99)00160-1.

Palmqvist, E., & Hahn, H. B. (2000). Bioresource Technology, 74, 25–33. doi:10.1016/S0960-8524(99)00161-3.

Cantarella, M., Cantarella, L., Gallifuoco, A., Spera, A., & Alfani, F. (2004). Biotechnology Progress, 20(1), 200–206. doi:10.1021/bp0257978.

Tengborg, C., Galbe, M., & Zacchi, G. (2001). Enzyme and Microbial Technology, 28, 835–844. doi:10.1016/S0141-0229(01)00342-8.

Larsson, S., Palmqvist, E., Hahn-Hagerdal, B., Tengborg, C., Stenberg, K., Zacchi, G., et al. (1999). Enzyme and Microbial Technology, 24(3–4), 151–159. doi:10.1016/S0141-0229(98)00101-X.

Ghosh, P. N. B., & Martin, W. R. B. (1982). Enzyme and Microbial Technology, 4, 425–430. doi:10.1016/0141-0229(82)90075-8.

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (Grant No. 20576013), Fund for the Doctoral Program of Higher Education of China (Grant No. 20030010004), the National Basic Research 973 Program of China (Grant No. 2007CB707804, 2007CB714304), the National High Technology Research and Development 863 Program of China (Grant No. 2006AA020103, 2006AA020102, 2006AA020201), the Natural Science Foundation of Beijing, China (Grant No. 2071002).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yu, J., Zhong, J., Zhang, X. et al. Ethanol Production from H2SO3-Steam-Pretreated Fresh Sweet Sorghum Stem by Simultaneous Saccharification and Fermentation. Appl Biochem Biotechnol 160, 401–409 (2010). https://doi.org/10.1007/s12010-008-8333-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12010-008-8333-x