Abstract

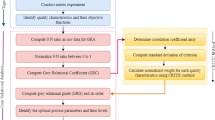

Aluminium Metal Matrix Composites (AMMC) made an exertion over traditional materials which found applications innumerous engineering domains like automotive components, marine and aerospace parts, owing to its enhanced characteristics such as elevated strength and toughness. The reinforcements that will be incorporated in the AMMC will make significant contributions to increasing material characteristics. Because of the addition of reinforcements, the fabricated composite became harder while comparing with the base material. The machining of these harder material is difficult with the aid of conventional machining approaches. As a result, an alternate approach for machining harder materials is required. Wire Electrical Discharge Machining (WEDM) is found to be one of the modern methods of machining for difficult to cut materials and also exclusively employed for producing intricate forms using any electrically conductive materials. In this proposed investigation, an explorative study has been done on investigating the machinability performance of stir casted aluminium based (AA2024) metal matrix composites with Boron nitride (BN—7%) as reinforcements. Pulse on (Ton), Pulse off (Toff) and peak current are the independent variables considered and Material Removal Rate, Dimensional Deviation are deemed as performance characteristics. The experimental planning and analysis of the process variables have been done by using Taguchi’s approach. Regression models for performance measurements during WEDM of aluminium metal matrix composites have been created. For defining the multi-aspect optimization model. Grey theory has been advocated. With an aid of evolved ANFIS model, the desired values have been foretold. The performance analysis on the developed model proves that the model predicts the desired performance measure with better precision.

Similar content being viewed by others

References

Ghasali, E., Pakseresht, A., Rahbari, A., Eslami-shahed, H., Alizadeh, M., Ebadzadeh, T.: Mechanical properties and microstructure characterization of spark plasma and conventional sintering of Al–SiC–TiC composites. J. Alloys Compd. 666, 366–371 (2016). https://doi.org/10.1016/j.jallcom.2016.01.118

Chandla, N.K., Kant, S., Goud, M.M.: Mechanical, tribological and microstructural characterization of stir cast Al-6061 metal/matrix composites—a comprehensive review. Sadhana (2021). https://doi.org/10.1007/s12046-021-01567-7

Alaneme, K.K., Aluko, A.O.: Fracture toughness () and tensile properties of as-cast and age-hardened aluminium (6063)–silicon carbide particulate composites. Sci. Iran. 19(4), 992–996 (2012). https://doi.org/10.1016/j.scient.2012.06.001

Ramesh, P., Nataraj, M.: Automotive industry application of aluminium-based hybrid metal matrix composite. Int. J. Heavy Veh. Syst. 27(1/2), 18 (2020). https://doi.org/10.1504/ijhvs.2020.104412

Alaneme, K.K., Babalola, S.A., Chown, L.H., Bodunrin, M.O.: Hot deformation behaviour of bamboo leaf ash-silicon carbide hybrid reinforced aluminium based composite. Manuf. Rev. (Les Ulis.) 7, 17 (2020). https://doi.org/10.1051/mfreview/2020014

Kumar, J., Singh, D., Kalsi, N.S.: Tribological, physical and microstructural characterization of silicon carbide reinforced aluminium matrix composites: a review. Mater. Today 18, 3218–3232 (2019). https://doi.org/10.1016/j.matpr.2019.07.198

Sharma, A., Sharma, V.M., Mewar, S., Pal, S.K., Paul, J.: Friction stir processing of Al6061-SiC-graphite hybrid surface composites. Mater. Manuf. Process. 33(7), 795–804 (2018). https://doi.org/10.1080/10426914.2017.1401726

Suresh, S., Shenbag, N., Moorthi, V.: Aluminium-titanium diboride (Al-TiB2) metal matrix composites: challenges and opportunities. Proced. Eng. 38, 89–97 (2012). https://doi.org/10.1016/j.proeng.2012.06.013

Yaghobizadeh, O., Baharvandi, H.R., Ahmadi, A.R., Aghaei, E.: Development of the properties of Al/SiC nano-composite fabricated by stir cast method by means of coating SiC particles with Al. Silicon 11(2), 643–649 (2019). https://doi.org/10.1007/s12633-018-9867-3

Sharifitabar, M., Sarani, A., Khorshahian, S., Shafiee Afarani, M.: Fabrication of 5052Al/Al2O3 nanoceramic particle reinforced composite via friction stir processing route. Mater. Eng. 32(8–9), 4164–4172 (2011). https://doi.org/10.1016/j.matdes.2011.04.048

Siva Prasad, D., Shoba, C.: Hybrid composites—a better choice for high wear resistant materials. J. Mater. Res. Technol. 3(2), 172–178 (2014). https://doi.org/10.1016/j.jmrt.2014.03.004

Manna, A., Bains, H.S., Mahapatra, P.B.: Experimental study on fabrication of Al—Al2O3/grp metal matrix composites. J. Compos. Mater. 45(19), 2003–2010 (2011). https://doi.org/10.1177/0021998310394691

Radhika, N., Subramanian, R.: Effect of reinforcement on wear behaviour of aluminium hybrid composites. Tribol. Mater. Surf. Interfaces 7(1), 36–41 (2013). https://doi.org/10.1179/1751584x13y.0000000025

Asif, M., Chandra, K., Misra, P.S.: Wear characteristic of Al-based metal matrix composites used for heavy duty brake pad applications. Mater. Sci. Forum 710, 407–411 (2012). https://doi.org/10.4028/www.scientific.net/msf.710.407

Palanisamy, D., Devaraju, A., Manikandan, N., Balasubramanian, K., Arulkirubakaran, D.: Experimental investigation and optimization of process parameters in EDM of aluminium metal matrix composites. Mater. Today 22, 525–530 (2020). https://doi.org/10.1016/j.matpr.2019.08.145

Karthik, S., Prakash, K.S., Gopal, P.M., Jothi, S.: Influence of materials and machining parameters on WEDM of Al/AlCoCrFeNiMo0.5 MMC. Mater. Manuf. Process. 34(7), 759–768 (2019). https://doi.org/10.1080/10426914.2019.1594250

Shridhar, T.N., Krishnamurthy, L., Sridhara, B.K.: Machinability studies on aluminium matrix hybrid composites. Adv. Mat. Res. 894, 27–31 (2014). https://doi.org/10.4028/www.scientific.net/amr.894.27

Rajmohan, T., Palanikumar, K.: experimental investigation and analysis of thrust force in drilling hybrid metal matrix composites by coated carbide drills. Mater. Manuf. Process. 26(8), 961–968 (2011). https://doi.org/10.1080/10426914.2010.523915

Ravi Kumar, K., Kiran, K., Sreebalaji, V.S.: Micro structural characteristics and mechanical behaviour of aluminium matrix composites reinforced with titanium carbide. J. Alloys Compd. 723, 795–801 (2017). https://doi.org/10.1016/j.jallcom.2017.06.309

Gururaja, S., Ramulu, M., Pedersen, W.: Machining of MMCs: a review. Mach. Sci. Technol. 17(1), 41–73 (2013). https://doi.org/10.1080/10910344.2012.747897

Kalaiselvan, K., Murugan, N., Parameswaran, S.: Production and characterization of AA6061–B4C stir cast composite. Mater. Eng. 32(7), 4004–4009 (2011). https://doi.org/10.1016/j.matdes.2011.03.018

Mavhungu, S.T., Akinlabi, E.T., Onitiri, M.A., Varachia, F.M.: Aluminum matrix composites for industrial use: advances and trends. Proced. Manuf. 7, 178–182 (2017). https://doi.org/10.1016/j.promfg.2016.12.045

Nturanabo, F., Masu, L.M., Govender, G.: Automotive light-weighting using aluminium metal matrix composites. Mater. Sci. Forum 828–829, 485–491 (2015). https://doi.org/10.4028/www.scientific.net/msf.828-829.485

Thévenot, F.: Boron carbide—a comprehensive review. J. Eur. Ceram. Soc. 6(4), 205–225 (1990). https://doi.org/10.1016/0955-2219(90)90048-k

Asm International, Materials Information Society. ASM Engineered Materials Reference Book. Asm International: Metals Park, Ohio (1994)

Thejasree, P., Manikandan, N.. Krishnamachary, P. C., Varaprasad, K. C., Joseph Selvi, B.: Application of Taguchi Approach on Wire Electrical Discharge Machining of SS304. No. 2021-28-0271. SAE Technical Paper (2021)

Thejasree, P., Manikandan, N., Binoj, J.S., Krishnamachary, P.C., Arulkirubakaran, D., Janardhana Reddy, J., Reddy, V., Saikiran, K., Vishnu Vardhan, C.: Application of multiple regression analysis for wire electrical discharge machining of stainless steel 304. In: Palani, I.A., Sathiya, P., Palanisamy, D. (eds.) recent advances in materials and modern manufacturing, pp. 175–183. Springer, Singapore (2022)

Palanisamy, D., Manikandan, N., Ramesh, R., Kathirvelan, M., Arulkirubakaran, D.: Machinability analysis and optimization of wire-EDM textured conventional tungsten carbide inserts in machining of 17–4 PH stainless steel. Mater. Today Proc. 39, 359–367 (2021)

Vishnu Vardhana Naidu, B., Varaprasad, K.C., Manikandan, N., Binoj, J.S.: Development of multiple regression models for wire spark erosion machining of AA2024 Alloy. In: Arockiarajan, A., Duraiselvam, M., Raju, R. (eds.) Advances in Industrial Automation and Smart Manufacturing, pp. 653–661. Springer, Singapore (2021)

Palanisamy, D., Devaraju, A., Manikandan, N., Balasubramanian, K., Arulkirubakaran, D.: Experimental investigation and optimization of process parameters in EDM of aluminium metal matrix composites. Mater. Today Proc. 22, 525–530 (2020)

Thejasree, P., Binoj, J.S., Manikandan, N., Krishnamachary, P.C., Raju, Ramesh, Palanisamy, D.: Multi objective optimization of wire electrical discharge machining on Inconel 718 using Taguchi grey relational analysis. Mater. Today Proc. 39, 230–235 (2021)

Manikandan, N., Raju, R., Palanisamy, D., Binoj, J.S.: Optimisation of spark erosion machining process parameters using hybrid grey relational analysis and artificial neural network model. Int. J. Mach. Mach. Mater. 22(1), 1–23 (2020)

Binoj, J. S., Thejasree, P., Palanisamy, D., Naidu, B., Manikandan, N., Raju, R., Manideep, M.: Application of multiple regression analysis for wire electrical discharge machining of Ti–6Al–4 V (Grade 5). In: Arockiarajan, A., Duraiselvam, M., Raju, R. (eds.) Recent Advances in Materials and Modern Manufacturing, pp. 1085–1093. Springer, Singapore (2022)

Selvi, B. J., Krishnamachary, P. C., Thejasree, P.: Experimental Analysis on Wire Electrical Discharge Machining of Nickel Alloy Using Taguchi Based Grey Relational Analysis. No. 2021-28-0273. SAE Technical Paper (2021)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hemalatha, A., Reddy, V.D. & Prasad, K. Evolution of regression and ANFIS models for wire spark erosion machining of aluminium metal matrix composites for aerospace applications. Int J Interact Des Manuf (2022). https://doi.org/10.1007/s12008-022-01012-x

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12008-022-01012-x