Abstract

Flexibility is one of the most important strategy parameters to achieve a long-term successful performance for a manufacturing company. Studies in the literature aim to operate a manufacturing system at optimum levels of flexibility parameters under its own manufacturing environment. This study aims to present an interactive analysis framework based on TOPSIS and Taguchi parameter design principles for investigating the effects of different levels of flexibility parameters on the performance of a flexible manufacturing cell (FMC). The main performance metric used in this study is manufacturing lead time. Other important metrics to evaluate quality control and inspection policies are also investigated in this study. To conclude, a combined model of an interactive approach based on TOPSIS and Taguchi methods are used to assess the effectiveness of the flexibility parameters for a FMC.

Similar content being viewed by others

References

Cochran, D.S., Jafri, M.U., Chu, A.K., Bi, Z.: Incorporating design improvement with effective evaluation using the manufacturing system design decomposition (MSDD). J. Ind. Inf. Integr. 2, 65–74 (2016)

Knopp, S., Dauzère-Pérès, S., Yugma, C.: Flexible job-shop scheduling with extended route flexibility for semiconductor manufacturing. Proc. Winter Simul. Conf. 2, 478–2489 (2014)

Gonğcalves J.P.M.: Robot interface in a flexible manufacturing cell, Msc Thesis, Lehigh University, USA (1992)

Cutkosky, M.R., Fussell, P.S., Milligan Jr, R.: Precision flexible machining cells within a manufacturing system (No. CMU-RI-TR-84–12). Carnegie-Mellon Univ. Pittsburgh Pa Robotics Inst (1984)

Leitão, P.J., Martins, C., Rocha, R.: Integration of CNC machines in flexible manufacturing cell. Present. Day-Proc. ESPRIT 5629, 207–217 (1995)

Chan, F.T.: The effects of routing flexibility on a flexible manufacturing system. Int. J. Comput. Integr. Manuf. 14(5), 431–445 (2001)

Lozano, S., Teba, J., Larrañeta, J., Onieva, L., de Toledo, P.A.: Dynamic part—routing in a flexible manufacturing system. Belgian J. Oper. Res. 34(4), 16–28 (1994)

Chandra, P., Tombak, M.M.: Models for the evaluation of routing and machine flexibility. Eur. J. Oper. Res. 60(2), 156–165 (1992)

Özkirim, M., Durmuşoğlu, M.B.: Dışsal rota esnekliğine sahip hücresel üretim sistemlerinin benzetim analizi. İTÜ J (D) 6(2), 41–52 (2010). (In Turkish)

Wadhwa, R.S.: Flexibility in manufacturing automation: a living lab case study of Norwegian metal casting SMEs. J. Manuf. Syst. 31, 444–454 (2012)

Galbraith, L., Greene, T.J.: Manufacturing system performance sensitivity to selection of product design metrics. J. Manuf. Syst. 14(2), 71–79 (1995)

Sharma, P., Jain, A.: Effect of routing flexibility and sequencing rules on performance of stochastic flexible job shop manufacturing system with setup times: simulation approach. Proc. Instit. Mech. Eng. Part B J. Eng. Manuf. 231(2), 329–345 (2017)

Pérez-Pérez, M., Bedia, A.-M.S., López-Fernández, M.-C., García-Piqueres, G.: Research opportunities on manufacturing flexibility domain: A review and theory-based research agenda. J. Manuf. Syst. 48, 9–20 (2018)

Jain, A., Jain, P., Chan, F.T., Singh, S.: A review on manufacturing flexibility. Int. J. Prod. Res. 51(19), 5946–5970 (2013)

Malhotra, M., Sharma, S.: Measurement equivalence using generalizability theory: an examination of manufacturing flexibility dimensions. Decis. Sci. 39(4), 643–669 (2008)

Wahab, M., Wu, D., Lee, C.: A generic approach to measuring the machine flexibility of manufacturing systems. Eur. J. Oper. Res. 186(1), 137–149 (2008)

Stecke, K.E.: Design, planning, scheduling, and control problems of Flexible manufacturing systems. In: Proceeding of the First ORSA/TIMS Special Interest Conference on FMS, Ann Arbor, MI (1984)

Taeho, P., Hochang, L., Heeseok, L.: FMS design model with multiple objectives using compromise programming. Int. J Prod. Res. 39(15), 3513–3528 (2001)

Fischer, X., Fadel, G., Ledoux, Y.: Interactive product design. In: Fischer, X. (ed.) Research in Interactive Design, vol. 3. Springer, Paris (2011)

Fiorini, L., Tabeau, K., D’Onofrio, G., et al.: Co-creation of an assistive robot for independent living: lessons learned on robot design. Int. J. Interact. Des. Manuf. (2019). https://doi.org/10.1007/s12008-019-00641-z

Nilufer, T., Stephen, H.: Security of smart manufacturing systems. J. Manuf. Syst. 47, 93–106 (2018)

Zignego, M.I., Gemelli, P.: A smart mockup for a small habitat. Int. J. Interact. Des. Manuf. (2019). https://doi.org/10.1007/s12008-019-00629-9

Hernandez-de-Menendez, M., Escobar Díaz, C., Morales-Menendez, R.: Technologies for the future of learning: state of the art. Int. J. Interact. Des. Manuf. (2019). https://doi.org/10.1007/s12008-019-00640-0

Zafrane, M.A., Bachir, A., Boudechiche, Z., et al.: Interactive design and advanced manufacturing of double solar panel deployment mechanism for CubeSat, part 1: electronics design. Int J Interact Des Manuf. 14, 503–518 (2020)

Yurdakul, M., Balci, A., Ic, Y.T.: A knowledge-based material selection system for interactive pressure vessel design. Int J Interact Des Manuf. 14, 323–343 (2020)

Fischer, X., Coutellier, D.: Editorial. Int. J. Interact. Des. Manuf. 1, 1–4 (2007)

Ranjit, K.R.” A primer on the Taguchi method: Van Nostrand Reinhold (1990)

Phadke, M.S.: Quality Engineering Using Robust Design. Prentice Hall, USA, New Jersey (1989)

Unal, R., Dean, E.B.: Taguchi approach to design optimization for quality and cost: an overview (1990)

Su, T.-L., Chen, H.-W., Lu, C.-F.: Systematic Optimization for the evaluation of the microinjection molding parameters of light guide plate with TOPSIS-based Taguchi method. Adv. Polym. Tech. 29(1), 54–63 (2010)

Hong, G.-B., Su, T.-L.: Statistical analysis of experimental parameters in characterization of ultraviolet-resistant polyester fiber using a TOPSIS-Taguchi method. Iran Polym. J. 21(12), 877–885 (2012)

Lan, T.-S.: Taguchi optimization of multi objective CNC machining using TOPSIS. Inf. Technol. J. 8(6), 917–922 (2009)

Liao, H.C.: Using PCR-TOPSIS to optimize Taguchi’s multi response problem. Int. J. Adv. Manuf. Tech. 22, 649–655 (2003)

Lu, J.-C., Yang, T., Su, C.-T.: Analysing optimum push/pull junction point location using multiple criteria decision-making for multistage stochastic production system. Int. J. Prod. Res. 50(19), 5523–5537 (2012)

Yang, T., Chou, P.: Solving a multi-response simulation-optimization problem with discrete variables using a multiple-attribute decision-making method. Math. Comput. Simulat. 68(1), 9–21 (2005)

İç, Y.T., Yıldırım, S.: MOORA-based Taguchi optimization for improving product or process quality. Int. J. Prod. Res. 51(11), 3321–3341 (2013)

Şimşek, B., İç, Y.T., Şimşek, E.H.: A TOPSIS-based Taguchi optimization to determine optimal mixture proportions of the high strength self-compacting concrete. Chemom. Intell. Lab. Syst. 125, 18–32 (2013)

Şimşek, B., İç, Y.T.: Multi-response simulation optimization approach for the performance optimization of an alarm monitoring center. Saf. Sci. 66, 61–74 (2014)

Şimşek, B., İç, Y.T., Şimşek, E.H.: “Hybridizing a fuzzy multi-response Taguchi optimization algorithm with artificial neural networks to solve standard ready-mixed concrete optimization problems. Int. J. Comput. Intell. Syst. 9(3), 525–543 (2016)

İç, Y.T., Elaldı, F., Keçeci, B.: Topsis based taguchi optimization of machining characteristics in end milling operation of kevlar-epoxy composites. J. Chin. Soc. Mech. Eng. 37(6), 653–662 (2016)

İç, Y.T., Saraloğlu Güler, E., Erbil, Ç.Z.: Reducing uncertainty in a type J thermocouple calibration process. Int. J. Thermophys. 40(53), 1–22 (2019)

Chavan, P., Patil, A.: Taguchi-based optimization of machining parameter in drilling spheroidal graphite using combined TOPSIS and AHP method. In: Venkata-Rao, R., Taler, J. (eds.) Advanced Engineering Optimization Through Intelligent Techniques Advances in Intelligent Systems and Computing, vol. 949. Springer, Singapore (2020)

Gopal, P.M., Prakash, K.S.: Minimization of cutting force, temperature and surface roughness through GRA TOPSIS and Taguchi techniques in end milling of Mg hybrid MMC. Measurement 116, 178–192 (2018)

Nguyen, H.-P., Pham, V.-D., Ngo, N.-V.: Application of TOPSIS to Taguchi method for multi-characteristic optimization of electrical discharge machining with titanium powder mixed into dielectric fluid. Int. J. Adv. Manuf. Technol. 98, 1179–1198 (2018)

Wang, S.T.: Integrating the Taguchi method and the multiattribute decision-making method to optimize the surface mount technology solder paste printing thickness process. Proc. Instit. Mech. Eng. Part B J. Eng. Manuf. 227(8), 1209–1217 (2013)

Internet: http://seykoc.com.tr/. Date: 14.12.2019 (18:00)

Internet: http://www.cadcamsektoru.com/makaleler/Talasli-Imalatta-Kullanilan-Kesici-TOOLlar-9949.htm; Date: 15.09. 2020 (14:30)

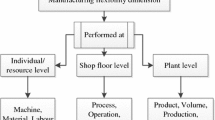

Browne, J., Dubois, D., Rathmill, K., Sethi, S.P., Stecke, K.E.: Classification of flexible manufacturing systems. FMS Magaz. 114–117 (1984)

Das, S.K.: The measurement of flexibility in manufacturing systems. Int. J. Flex. Manuf. Syst. 8, 67–93 (1996)

Funding

This research was supported by Baskent University, Ankara, Turkey, under the Contract No. BA/FM-15.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declared no potential conflicts of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendices

Appendix A: Cutting tool information

In this study three different end mill cutters were used with respect to standard DIN 844/BN HSS-E Form B which are alloyed as 303/20, HSS-E 8 Co%.

-

d = 3 mm, 4-necked, y = 30° helix angle with finger HSS cutter

-

d = 4 mm, 4-necked, y = 30° helix angle with finger HSS cutter

-

d = 5 mm, 4-necked, y = 30° helix angle with finger HSS cutter

See Fig.

6.

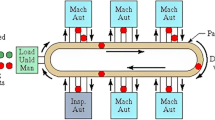

Appendix B: Experimental set-up

The components are as follows:

-

1.

Flexible manufacturing system control computer

-

2.

CNC control computer (GE Fanuc Series 21)

-

3.

Robot Arm (Festo RV-2AJ-SI3)

-

4.

CNC vertical machining center (EMCO PC MiI 55)

-

5.

Control station

-

6.

Material handling conveyor (FESTO)

See Figs.

7 and

8.

Appendix C: Conducting to experiment

Various assumptions are made as follows in this study [5]:

-

The system is fully automated.

-

All machines are 100% reliable.

-

There is no scrap produced by machines.

-

Setup times of the machines are not included in the processing time.

-

Once the process starts in the machime, it is not allowed to cancel the operation.

-

The machine can handle only one part of the cycle.

-

Pallet capacity is three.

-

Pallets are not allowed to enter the processing area if the part is not ready.

-

All pallets are 100% reliable.

-

Operation ends when all the parts’ processes are completed.

See Fig.

9.

Appendix D: ANOVA tables

See Tables

30,

31,

32 and

33.

Appendix E: Taguchi results via graphical illustrations

See Figs.

10,

11,

12 and

13.

Appendix F: Taguchi results via graphical illustrations (continue)

See Figs.

14,

15,

16,

17,

18 and

19.

Rights and permissions

About this article

Cite this article

İç, Y.T., Şaşmaz, T., Yurdakul, M. et al. Analysis of the manufacturing flexibility parameters with effective performance metrics: a new interactive approach based on modified TOPSIS-Taguchi method. Int J Interact Des Manuf 16, 197–225 (2022). https://doi.org/10.1007/s12008-021-00799-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-021-00799-5