Abstract

Surface roughness is an important design specification for injection-molded plastic parts that are widely used in the consumer electronics, packaging, and automotive industry. Surface roughness serves both the appearance and functional requirements of injection moldings. It is not only influenced directly by the mold cavity surface, but also by injection molding parameters. However, there are few systematic studies on the effects of molding parameters on the surface roughness of molded parts. This study is to investigate the effects of molding parameters on the surface roughness of injection molded polypropylene parts. The molding parameters studied include cooling time, injection speed, holding pressure, and holding time. It turns out that the mold surface roughness plays the dominant role, while the molding parameters also exhibit a large influence on the surface roughness of molded parts. Among the parameters studied, the injection speed has the largest effect while the cooling time having the least effect on the surface roughness. This study implies that the surface roughness of molded parts can be cost effectively manipulated to a certain degree through controlling molding parameters, instead of modifying the surface furnish of mold cavity at a high cost.

Similar content being viewed by others

References

Gong, G., Chen, J.C., Guo, G.: Enhancing tensile strength of injection molded fiber reinforced composites using the Taguchi-based six sigma approach. Int. J. Adv. Manuf. Technol. 91(9–12), 3385–3393 (2017)

Guo, G., Finkenstadt, V.L., Nimmagadda, Y.: Mechanical properties and water absorption behavior of injection-molded wood fiber/carbon fiber high-density polyethylene hybrid composites. Adv. Compos. Hybrid Mater. 2(4), 690–700 (2019)

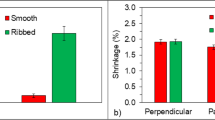

Abdul, R., Guo, G., Chen, J.C., Yoo, J.J.W.: Shrinkage prediction of injection molded high density polyethylene parts with taguchi/artificial neural network hybrid experimental design. Int. J. Interact. Des. Manuf. 14(2), 345–357 (2019)

Guo, G., Li, Y., Zhao, X., Rizvi, R.: Tensile and longitudinal shrinkage behaviors of polylactide/wood-fiber composites via direct injection molding. Polym. Compos. 41(11), 4663–4677 (2020)

Chen, J.C., Guo, G., Wang, W.N.: Artificial neural network-based online defect detection system with in-mold temperature and pressure sensors for high precision injection molding. Int. J. Adv. Manuf. Technol. 110(7), 2023–2033 (2020)

Zhang, H.L., Ong, N.S., Lam, Y.C.: Mold surface roughness effects on cavity filling of polymer melt in micro injection molding. Int. J. Adv. Manuf. Technol. 37(11–12), 1105–1112 (2008)

Surace, R., Sorgato, M., Bellantone, V., Modica, F., Lucchetta, G., Fassi, I.: Effect of cavity surface roughness and wettability on the filling flow in micro injection molding. J. Manuf. Process. 43, 105–111 (2019)

Liu, Y., Gehde, M.: Effects of surface roughness and processing parameters on heat transfer coefficient between polymer and cavity wall during injection molding. Int. J. Adv. Manuf. Technol. 84(5–8), 1325–1333 (2016)

Kuroda, S., Mizutani, A., Ito, H.: Effect of talc size on surface roughness and glossiness of polypropylene injection molding application to automotive plastics. Polym. Eng. Sci. 60(1), 132–139 (2020)

Kaneda, R., Takahashi, T., Takiguchi, M., Hijikata, M., Ito, H.: Optical properties of HDPE in injection molding and injection press molding for IR system lenses part II: mold temperature and surface roughness effects on injection molding. Int. Polym. Proc. 32(2), 237–244 (2017)

Theilade, U.A., Hansen, H.N.: Surface microstructure replication in injection molding. Int. J. Adv. Manuf. Technol. 33(1–2), 157–166 (2007)

Lucchetta, G., Fiorotto, M., Bariani, P.F.: Influence of rapid mold temperature variation on surface topography replication and appearance of injection-molded parts. CIRP Ann. 61(1), 539–542 (2012)

Wang, G., Zhao, G., Wang, X.: Experimental research on the effects of cavity surface temperature on surface appearance properties of the moulded part in rapid heat cycle moulding process. Int. J. Adv. Manuf. Technol. 68(5–8), 1293–1310 (2013)

Murakami, O., Kotaki, M., Hamada, H.: Effect of molecular weight and molding conditions on the replication of injection moldings with micro-scale v-groove features. Polym. Eng. Sci. 48(4), 697–704 (2008)

Vera, J., Brulez, A.C., Contraires, E., Larochette, M., Valette, S., Benayoun, S.: Influence of the polypropylene structure on the replication of nanostructures by injection molding. J. Micromech. Microeng. 25(11), 115027 (2015)

Oliveira, M.J., Brito, A.M., Costa, M.C., Costa, M.F.: Gloss and surface topography of ABS: a study on the influence of the injection molding parameters. Polym. Eng. Sci. 46(10), 1394–1401 (2006)

Chivatanasoontorn, V., Tsukise, S., Kotaki, M.: Surface texture effect on scratch behavior of injection molded plastics. Polym. Eng. Sci. 52(9), 1862–1867 (2012)

Lee, J., Turng, L.S.: Improving surface quality of microcellular injection molded parts through mold surface temperature manipulation with thin film insulation. Polym. Eng. Sci. 50(7), 1281–1289 (2010)

Chen, S.-C., Lin, Y.-W., Chien, R.-D.: Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv. Polym. Technol. 27, 224–232 (2008)

Chen, S.-C., Hsu, P.-S., Hwang, S.-S.: The effects of gas counter pressure and mold temperature variation on the surface quality and morphology of the microcellular polystyrene foams. J. Appl. Polym. Sci. 127, 4769–4776 (2013)

Guo, G., Chen, J.C., Gong, G.: Injection molding of polypropylene hybrid composites reinforced with carbon fiber and wood fiber. Polym. Compos. 39(9), 3329–3335 (2018)

Guo, G., Kethineni, C.: Direct injection molding of hybrid polypropylene/wood-fiber composites reinforced with glass fiber and carbon fiber. Int. J. Adv. Manuf. Technol. 106(1–2), 201–209 (2020)

Syed, S.F., Chen, J.C., Guo, G.: Optimization of tensile strength and shrinkage of talc-filled polypropylene as a packaging material in injection molding. J. Pack. Technol. Res. 4(1), 69–78 (2020)

Kim, Y.S., Guo, G., Park, C.B., Wang, K.H.: Processing/structure/property relationships for artificial wood made from stretched PP/wood-fiber composites. Polym. Eng. Sci. 49(1), 11–16 (2009)

Shoemaker, J.: Moldflow Design Guide: A Resource for Plastics Engineers. Hanser Gardner Publications, Inc (2006)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Guo, G. Investigation on surface roughness of injection molded polypropylene parts with 3D optical metrology. Int J Interact Des Manuf 16, 17–23 (2022). https://doi.org/10.1007/s12008-021-00796-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-021-00796-8