Abstract

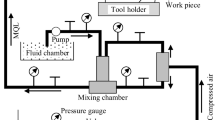

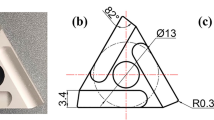

Cryogenic cooling is attributed as a green option to counter the high temperatures developed in machining process. The parameters specific to the cryogenic cooling such as jet radius and jet location have controlling influence on the machining performance. Inconel 718 is one of the most prominent aeronautic alloys, mainly used in the aerospace industry due to its high strength and ability to retain properties at very high temperatures. Inconel 718 is a hard to cut material due its low thermal conductivity and work hardening behavior. The present study that investigates the impact of cryogenic cooling using liquid nitrogen coolant on orthogonal turning of Inconel 718 for different values of jet radius, jet location and cutting speeds. The study incorporated a finite element model to simulate the different machining test conditions. The virtual assessment of cryogenic cutting process is beneficial for the decision making that how these parameters can contribute towards final decision making. The dissipation of heat at cutting edge and presence of jet of cryogenic coolant was simulated and analyzed for different jet radii, jet locations and cutting speeds. The study detected shear angle and evaluated chip compression ratio to understand the plastic deformation and related effects. The study revealed that cutting temperature decreased with increasing flow of LN2 at the cutting edge while the cutting force increased with high flow of coolant.

Similar content being viewed by others

References

Jayakrishna, K., Kar, V.R., Sultan, M.T.H., Rajesh, M.: Materials selection for aerospace components. In: Jawaid, M., Thariq, M., Saba, N. (eds.) Woodhead Publishing Series in Composites Science and Engineering, pp. 1–18. Woodhead Publishing, Sawston (2018)

Parida, A.K., Maity, K.: Comparison the machinability of Inconel 718, Inconel 625 and Monel 400 in hot turning operation. Eng. Sci. Technol. Int. J. 21, 364–370 (2018). https://doi.org/10.1016/j.jestch.2018.03.018

S. Rajaram GRRBNG, : Investigation of turning parameters of machining Inconel 718 using titanium and carbide inserts. Mater Today Proc. 5, 11283–11294 (2018)

Xavior, M.A., Manohar, M., Jeyapandiarajan, P., Madhukar, P.M.: Tool wear assessment during machining of Inconel 718. Procedia Eng. 174, 1000–1008 (2017). https://doi.org/10.1016/j.proeng.2017.01.252

Pandian, P.P., Rout, I.S.: Parametric investigation of machining parameters in determining the machinability of Inconel 718 using Taguchi technique and grey relational analysis. Procedia Comput. Sci. 133, 786–792 (2018). https://doi.org/10.1016/j.procs.2018.07.118

Wang, Z.Y., Rajurkar, K.P., Fan, J., et al.: Hybrid machining of Inconel 718. Int. J. Mach. Tools Manuf. 43, 1391–1396 (2003). https://doi.org/10.1016/S0890-6955(03)00134-2

Pereira, O., Urbikain, G., Rodríguez, A., et al.: Internal cryolubrication approach for Inconel 718 milling. Procedia Manuf. 13, 89–93 (2017). https://doi.org/10.1016/j.promfg.2017.09.013

Iturbe, A., Hormaetxe, E., Garay, A., Arrazola, P.J.: surface integrity analysis when machining Inconel 718 with conventional and cryogenic cooling. Procedia CIRP 45, 67–70 (2016). https://doi.org/10.1016/j.procir.2016.02.095

Nasr, M.N.A., Outeiro, J.C.: Sensitivity analysis of cryogenic cooling on machining of magnesium alloy AZ31B-O. Procedia CIRP 31, 264–269 (2015). https://doi.org/10.1016/j.procir.2015.03.030

D’Addona, D.M., Raykar, S.J., Narke, M.M.: High speed machining of Inconel 718: tool wear and surface roughness analysis. Procedia CIRP 62, 269–274 (2017). https://doi.org/10.1016/j.procir.2017.03.004

Musfirah, A.H., Ghani, J.A., Haron, C.H.C.: Tool wear and surface integrity of Inconel 718 in dry and cryogenic coolant at high cutting speed. Wear 376–377, 125–133 (2017). https://doi.org/10.1016/j.wear.2017.01.031

Imbrogno, S., Sartori, S., Bordin, A., et al.: Machining simulation of Ti6Al4V under dry and cryogenic conditions. Procedia CIRP 58, 475–480 (2017). https://doi.org/10.1016/j.procir.2017.03.263

Rotella, G., Umbrello, D.: Finite element modeling of microstructural changes in dry and cryogenic cutting of Ti6Al4V alloy. CIRP Ann. Manuf. Technol. 63, 69–72 (2014). https://doi.org/10.1016/j.cirp.2014.03.074

Kheireddine, A.H., Ammouri, A.H., Lu, T., et al.: An FEM analysis with experimental validation to study the hardness of in-process cryogenically cooled drilled holes in Mg AZ31b. Procedia CIRP 8, 588–593 (2013). https://doi.org/10.1016/j.procir.2013.06.156

Sun, Y., Huang, B., Puleo, D.A., Jawahir, I.S.: Enhanced machinability of Ti-5553 alloy from cryogenic machining: comparison with MQL and flood-cooled machining and modeling. Procedia CIRP 31, 477–482 (2015). https://doi.org/10.1016/j.procir.2015.03.099

Pusavec, F., Lu, T., Courbon, C., et al.: Analysis of the influence of nitrogen phase and surface heat transfer coefficient on cryogenic machining performance. J. Mater. Process. Technol. 233, 19–28 (2016). https://doi.org/10.1016/j.jmatprotec.2016.02.003

Lequien, P., Poulachon, G., Outeiro, J.C., Rech, J.: Hybrid experimental/modelling methodology for identifying the convective heat transfer coefficient in cryogenic assisted machining. Appl. Therm. Eng. 128, 500–507 (2018). https://doi.org/10.1016/j.applthermaleng.2017.09.054

Davoudinejad, A., Chiappini, E., Tirelli, S., et al.: Finite element simulation and validation of chip formation and cutting forces in dry and cryogenic cutting of Ti–6Al–4V. Procedia Manuf. 1, 728–739 (2015). https://doi.org/10.1016/j.promfg.2015.09.037

Piispanen, V.: Theory of formation of metal chips. J. Appl. Phys. 19, 876–881 (1948). https://doi.org/10.1063/1.1697893

Merchant, M.E.: Mechanics of the metal cutting process. I. Orthogonal cutting and a type 2 chip. J. Appl. Phys. 16, 267–275 (1945). https://doi.org/10.1063/1.1707586

Astakhov, V.P., Shvets, S.: The assessment of plastic deformation in metal cutting. J. Mater. Process. Technol. 146, 193–202 (2004). https://doi.org/10.1016/j.jmatprotec.2003.10.015

Man, X., Ren, D., Usui, S., et al.: Validation of finite element cutting force prediction for end milling. Procedia CIRP 1, 663–668 (2012). https://doi.org/10.1016/j.procir.2012.04.119

Jafarian, F., Imaz Ciaran, M., Umbrello, D., et al.: Finite element simulation of machining Inconel 718 alloy including microstructure changes. Int. J. Mech. Sci. 88, 110–121 (2014). https://doi.org/10.1016/j.ijmecsci.2014.08.007

Lee, W.-S., Lin, C.-F., Chen, T.-H., Chen, H.-W.: Dynamic impact response of Inconel 718 alloy under low and high temperatures. Mater. Trans. 52, 1734–1740 (2011). https://doi.org/10.2320/matertrans.M2011130

ThirdWaveSystems: Third Wave AdvantEdgeTM User’s Manual Version 7.3 (2017)

Banerjee, N., Sharma, A.: Identification of a friction model for minimum quantity lubrication machining. J. Clean. Prod. 83, 437–443 (2014). https://doi.org/10.1016/j.jclepro.2014.07.034

Uhlmann, E., Henze, S., Brömmelhoff, K., Reimers, W.: Cutting simulation with consideration of the material hardening in the shear zone of AISI1045. Procedia CIRP 58, 91–96 (2017). https://doi.org/10.1016/j.procir.2017.03.199

Lotfi, M., Amini, S.: Effect of ultrasonic vibration on frictional behavior of tool–chip interface: Finite element analysis and experimental study. Proc. Inst. Mech. Eng. B J. Eng. Manuf. (2016). https://doi.org/10.1177/0954405416666895

Raof, N.A., Ghani, J.A., Syarif, J., et al.: Comparison of dry and cryogenic machining on chip formation and coefficient of friction in turning AISI 4340 alloy steel. Appl. Mech. Mater. 554, 7–11 (2014). https://doi.org/10.4028/www.scientific.net/AMM.554.7

Dilip Jerold, B., Pradeep Kumar, M.: Experimental investigation of turning AISI 1045 steel using cryogenic carbon dioxide as the cutting fluid. J Manuf. Process. 13, 113–119 (2011). https://doi.org/10.1016/j.jmapro.2011.02.001

Thamizhmanii, S., Sulaiman, H.: Machinability study using chip thickness ratio on difficult to cut metals by CBN cutting tool. Key Eng. Mater. 504–506, 1317–1322 (2012). https://doi.org/10.4028/www.scientific.net/KEM.504-506.1317

Yao, C., Zhou, Z., Jiyin Zhang, D., LT, : Experimental study on cutting force of face-turning Inconel 718 with ceramic tools and carbide tools. Adv. Mech. Eng. 9, 1–9 (2017)

Hribersek, M., Pusavec, F., Rech, J., Kopac, J.: Modeling of machined surface characteristics in cryogenic orthogonal turning of Inconel 718. Mach. Sci. Technol. 22, 829–850 (2018). https://doi.org/10.1080/10910344.2017.1415935

de Paula Oliveira, G., Fonseca, M.C., Araujo, A.C.: Residual stresses and cutting forces in cryogenic milling of Inconel 718. Procedia CIRP 77, 211–214 (2018). https://doi.org/10.1016/J.PROCIR.2018.08.289

Wang, Z.Y., Rajurkar, K.P.: Cryogenic machining of hard-to-cut materials. Wear 239, 168–175 (2000). https://doi.org/10.1016/S0043-1648(99)00361-0

Bhattacharyya, D., M.N. Allen SJM, : Cryogenic machining of Kevlar composites. Mater. Manuf. Process 8, 631–651 (1993). https://doi.org/10.1016/B978-0-85709-030-0.50014-X

Yildiz, Y., Nalbant, M.: A review of cryogenic cooling in machining processes. Int. J. Mach. Tools Manuf. 48, 947–964 (2008). https://doi.org/10.1016/j.ijmachtools.2008.01.008

Hong, S.Y., Ding, Y., Jeong, W.C.: Friction and cutting forces in cryogenic machining of Ti–6Al–4V. Int. J. Mach. Tools Manuf. 41, 2271–2285 (2001). https://doi.org/10.1016/S0890-6955(01)00029-3

Boothroyd, G., Knight, W.A.: Fundamentals of Machining and Machine Tools, 2nd edn. Marcel Dekker, New York (1989)

Kalpakjian, S., Schmid, S.R.: Manufacturing Engineering and Technology, 6th edn. Prentice hall, Singapore (2010)

Liu, W., Ren, D., Usui, S., Marusich, T.D.: A gear cutting predictive model using the finite element method. In: 14th CIRP Conference on Modeling of Machining Operations, CIRP Procedia, vol 8, pp. 51–56 (2013)

Acknowledgements

Authors sincerely acknowledge the financial support provided by Dubai Silicon Oasis Authority (DSOA) and Rochester Institute of Technology - Dubai (RIT-D).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nouzil, I., Pervaiz, S. & Kannan, S. Role of jet radius and jet location in cryogenic machining of Inconel 718: a finite element method based approach. Int J Interact Des Manuf 15, 1–19 (2021). https://doi.org/10.1007/s12008-020-00703-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-020-00703-7