Abstract

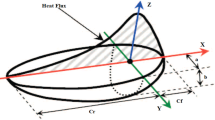

This work is a contribution to the field of gas transport as well as the safety of pipelines and stations under pressure, to better understand this study, we will use experimental results of two tensile tests of two pipelines (APIX52, APIX60), her thickness is 5.1 and 7.1 mm respectively and outside diameter is 508 mm. Using code abaqus calculation, we will simulate two pipeline with presence of a semi-elliptical crack (0.4 mm \(\times \) 0.8 mm), while varying the parameters thickness (5.1 and 7.1 mm), yield strength (359, 414 MPa) and pressure (7.1, 10.4 MPa) to calculate J integral in each case. Once the values of J integral calculated and compared to other authors, we will exploit these results with the MODDE 5.0 software in order to provide an analysis based on the DOE method to determine the influence of each parameter on the J integral, and see which is the most influential and Secondly proposed a model that represents the analytical part of this method and give confidence interval of each parameter.

Similar content being viewed by others

References

Majid, Z., Mohsin, R., Yaacob, Z., Hassan, Z.: Failure analysis of natural gas pipes. Eng. Fail. Anal. 17(4), 818–837 (2010)

Nagesh, D., Datta, G.: Modeling of fillet welded joint of GMAW process: integrated approach using DOE, ANN and GA. Int. J. Interact. Des. Manuf. 2(3), 127–136 (2008)

Wang, J., Atrens, A., Cousens, D., Kinaev, N.: Microstructure of X52 and X65 pipeline steels. J. Mater. Sci. 34(8), 1721–1728 (1999)

Hasanaj, A., Gjeta, A., Kullolli, M.: Analyzing defects with failure assessment diagrams of gas pipelines. Int. J. Mech. Aerosp. Ind. Mechatron. Eng. 8, 1032–1034 (2014)

Valinejad, R., Nazar, A.R.S.: An experimental design approach for investigating the effects of operating factors on the wax deposition in pipelines. Fuel 106, 843–850 (2013)

Slimane, A., Bouchouicha, B., Benguediab, M., Slimane, S.-A.: Parametric study of the ductile damage by the Gurson-Tvergaard-Needleman model of structures in carbon steel A48-AP. J. Mater. Res. Technol. 4(2), 217–223 (2015)

Zhou, Y., Zhang, Z., Zhong, Q.: Improved reliability analysis method based on the failure assessment diagram. Chin. J. Mech. Eng. 25(4), 832–837 (2012)

Kumar, J.P.N., Kumar, S.J., Jeyathilak, R.S., Venkatesh, M., Christopher, A.S., Ganesh, K.: Effect of design parameters on the static mechanical behaviour of metal bellows using design of experiment and finite element analysis. Int. J. Interact. Des. Manuf. (IJIDeM) 10(1), 1–11 (2016)

Noorul Haq, A., Guharaja, S., Karuppannan, K.: Parameter optimization of CO\(_{2}\) casting process by using Taguchi method. Int. J. Interact. Des. Manuf. 3(1), 41–50 (2009)

Nagesh, D., Datta, G.: Modeling of fillet welded joint of GMAW process: integrated approach using DOE, ANN and GA. Int. J. Interact. Des. Manuf. 2(3), 127–136 (2008)

Phongthanapanich, S., Potjananapasiri, K., Dechaumphai, P.: J-integral calculation by domain integral technique using adaptive finite element method. Struct. Eng. Mech. 28(4), 461–477 (2008)

Ruggieri, C., Dotta, F.: Numerical modeling of ductile crack extension in high pressure pipelines with longitudinal flaws. Eng. Struct. 33(5), 1423–1438 (2011)

Bach, M., Wang, X.: Constraint-based fracture mechanics analysis of cylinders with internal circumferential cracks. Struct. Eng. Mech. 47(1), 131–147 (2013)

Amirat, A., Chaoui, K., Azari, Z., Pluvinage, G.: Residual stress analysis in seamless API X60 steel gas pipelines. Sci. Technol. B 21, 7–10 (2004)

Fang, J., Zhang, J., Wang, L.: Evaluation of cracking behavior and critical CTOA values of pipeline steel from DWTT specimens. Eng. Fract. Mech. 124, 18–29 (2014)

Lu, Z., Liu, Y.: Concurrent fatigue crack growth simulation using extended finite element method. Front. Archit. Civ. Eng. China 4(3), 339–347 (2010)

Zhang, Y., et al.: Elastic-plastic fracture analyses for pipeline girth welds with 3D semi-elliptical surface cracks subjected to large plastic bending. Int. J. Press. Vessels Pip. 105, 90–102 (2013)

Hertelé, S., De Waele, W., Denys, R., Verstraete, M.: Justification of the mapping approach for finite element modelling of ductile tearing. In: Paper Presented at the Sustainable Construction and Design (SCAD-2012) (2012)

Slimane, A., Bouchouicha, B., Benguediab, M., Slimane, S.A.: Contribution to the study of fatigue and rupture of welded structures in carbon steel-a48 ap: experimental and numerical study. Trans. Indian Inst. Met. 68(3), 465–477 (2015)

Moghaddam, A.S., Mohammadnia, S., Sagharichiha, M.: Analysis of offshore pipeline laid on 3D seabed configuration by Abaqus. Ocean Syst. Eng. 5(1), 31–40 (2015)

Chatterjee, A., Kumar, S., Saha, P., Mishra, P., Choudhury, A.R.: An experimental design approach to selective laser sintering of low carbon steel. J. Mater. Process. Technol. 136(1), 151–157 (2003)

Ilzarbe, L., Álvarez, M.J., Viles, E., Tanco, M.: Practical applications of design of experiments in the field of engineering: a bibliographical review. Qual. Reliab. Eng. Int. 24(4), 417–428 (2008)

Acknowledgements

I want to thank all the authors for their insightful comments and suggestions.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Kaddour, B., Bouchouicha, B., Benguediab, M. et al. Modeling and optimization of a cracked pipeline under pressure by an interactive method: design of experiments. Int J Interact Des Manuf 12, 409–419 (2018). https://doi.org/10.1007/s12008-017-0385-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12008-017-0385-0