Abstract

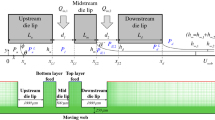

Slot coating is perhaps one of the most successful film manufacturing methods and is used to produce a wide variety of products. It is a pre-metered method and ideal for high-precision coating: the steady-state thickness is precisely controlled by the flow rate fed to the die and the web speed. However, the coating method is surrounded by small-scale disturbances that can destroy film thickness uniformity. Among various disturbances, a periodic change of the coating gap, the so-called gap disturbance, is considered the most dangerous in previous studies, e.g., Romero and Carvalho (Chem Eng Sci 63(8):2161–2173, 2008), Tsuda et al. (AIChE J 56(9):2268–2279, 2010), and Lee and Nam (AIChE J, 2015). However, the effects of fluid properties, operating conditions, and die configurations on the slot coating flow under gap disturbances are not examined in detail. In this study, we revisit the computer-aided analysis of transient slot coating flow designed to predict the thickness variations under gap disturbance. Extensive computational predictions reveal important parameters for suppressing film nonuniformity that can be induced by gap disturbance.

Similar content being viewed by others

References

Higgins, BG, Scriven, LE, "Capillary Pressure and Viscous Pressure Drop Set Bounds on Coating Bead Operability." Chem. Eng. Sci., 35 (3):673–682 (1980)

Nam, J, Carvalho, MS, "Flow in Tensioned-Web-Over-Slot Die Coating: Effect of Die Lip Design." Chem. Eng. Sci., 65 (13):3957–3971 (2010)

Sartor, L, "Slot Coating: Fluid Mechanics and Die Design". PhD Thesis, University of Minnesota, 1990

Perez, EB, and Carvalho, MS, "Optimization of Slot-Coating Processes: Minimizing the Amplitude of Film-Thickness Oscillation." J. Eng. Math., 71 (1):97–108 (2011)

Romero, OJ, Carvalho, MS, "Response of Slot Coating Flows to Periodic Disturbances." Chem. Eng. Sci., 63 (8):2161–2173 (2008)

Tsuda, T, de Santos, JM, Scriven, LE, "Frequency Response Analysis of Slot Coating." AIChE J., 56 (9):2268–2279, (2010)

Lee, S, Nam, J, “Analysis of Slot Coating Flow Under Tilted Die.” AIChE J. (2015). doi:10.1002/aic.14752

Yasuda, H, "The Two-Center Expansion of an Exponential Function: The Reduction of Yasudas Expression to that of Briels." J. Chem. Phys., 74 (11):6531–6532, (1981)

De Santos, JM, "Two-Phase Cocurrent Downflow Through Constricted Passages". PhD Thesis, University of Minnesota, 1991

Escudier, MP, Gouldson, IW, Pereira, AS, Pinho FT, Poole, RJ, "On the Reproducibility of the Rheology of Shear-Thinning Liquids." J. NonNewtonian Fluid Mech., 97 (2):99–124, (2001)

Kamişli, F, Ryan, M E, "Perturbation Method in Gas-Assisted Power-Law Fluid Displacement in a Circular Tube and a Rectangular Channel. " Chem. Eng. J., 75 (3):167–176, (1999)

Nam, J, Scriven, LE, Cavalho, MS, "Tracking Birth of Vortex in Flows." J. Comput. Phys., 228 (12):4549–4567 (2009)

Beguin, AE, "Method of Coating Strip Material", US Patent 2,681,294, 1954

Acknowledgments

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2013R1A1A1004986) and by the Global Ph.D Fellowship Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Education (2014H1A2A1019789). This work was also supported by LG Chem (No. AP1400056).

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was presented at the 17th International Coating Science and Technology Symposium, September 7–10, 2014, in San Diego, CA (USA).

Rights and permissions

About this article

Cite this article

Lee, S., Nam, J. Response of slot coating flow to gap disturbances: effects of fluid properties, operating conditions, and die configurations. J Coat Technol Res 12, 949–958 (2015). https://doi.org/10.1007/s11998-015-9684-1

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-015-9684-1