Abstract

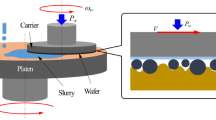

The dominant method of atomizing automotive paint is through the use of rotating bell sprayers. For this class of atomizer, the problem of paint thickness across the bell has been theoretically solved on a representative geometry that includes factors such as fluid flow rate, bell speed, bell cup radius, and fluid properties. It was assumed that the paint film eventually forms uniform ligaments at the bell cup edge that break due to hydrodynamic stability during the paint spray process; thus, creating a characteristic particle size distribution for the spray. These particle size distributions will vary as the spray parameters, specifically fluid flow rate, bell speed, and bell cup radius, vary. The theoretical model that has been developed strongly correlates to the literature data available for paint droplet size from rotary bell atomizers. Expansion of the correlation of the theoretical model to paint appearance wavelength measurements, Wc and Wd, in place of droplet size provides further understanding of the effect of paint spray parameters on paint appearance. Use of these correlations can help to optimize paint appearance and improve paint spray simulation results.

Similar content being viewed by others

References

Pimbley, WT, Lee, HC, “Satellite Droplet Formation in a Liquid Jet.” IBM J. Res. Dev., 21 21 (1977)

Debler, W, Yu, D, “The Break-up of Laminar Liquid Jets.” Proc. R. Soc. Lond. A, 415 107–119 (1988)

Bousfield, DW, et al., “Nonlinear Analysis of the Surface Tension Driven Breakup of Viscoelastic Filaments.” J. Non-Newton. Fluid Mech., 21 79 (1986)

Drazin, PG, Reid, WH, Hydrodynamic Stability. Cambridge University Press, Cambridge (1981)

Ellwood, KRJ, et al., “Laminar Jets of Bingham-Plastic Liquids.” J. Rheol., 34 (6) 787–812 (1990)

Bailey, AG, Electrostatic Spraying of Liquids. Wiley, New York (1988)

Washo, BD, “Rheology and Modeling of the Spin Coating Process.” IBM. J. Res. Dev., 21 (2) 190–198 (1997)

Acrivos, A, Shah, MJ, Petersen, EE, “On the Flow of a Non-Newtonian Liquid on a Rotating Disk.” J. Appl. Phys., 31 963–968 (1960)

Jenekhe, SA, Schuldt, SB, “Coating Flow of Non-Newtonian Fluids on a Flat Rotating Disk.” Ind. Eng. Chem. Fundam., 23 432–436 (1984)

Papanastasiou, TC, Alexandrou, AN, Graebel, WP, “Rotating Thin Films in Bell Sprayers and Spin Coatings.” J. Rheol., 32 (5) 485–509 (1988)

Bell, GC, Hockberg, J, “Mechanics of Electrostatic Atomization, Transport, and Deposition of Coatings.” In: Parfitt, GD (ed.) Organic Coatings Science and Technology, Vol. 5, pp. 325–357. Marcel Dekker, New York (1981)

Kirchner, E, “Film Shrinkage and Flake Orientation.” Prog. Org. Coat., 65 (3) 333–336 (2009)

Di Domenico, J, Henshaw, P, “The Effects of Basecoat Bell Application Parameters on Elements of Appearance for an Automotive Coatings Process.” J. Coat. Technol. Res., 9 (6) 675–686 (2012)

Chandrasekhar, S, Hydrodynamic and Hydromagnetic Stability. Clarendon Press, Oxford (1961)

Panton, RL, Incompressible Flow. Wiley, New York (1984)

Ellwood, KRJ, Braslaw, J, “A Finite-Element Model for an Electrostatic Bell Sprayer.” J. Electrost., 45 1–23 (1998)

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ellwood, K.R.J., Tardiff, J.L. & Alaie, S.M. A simplified analysis method for correlating rotary atomizer performance on droplet size and coating appearance. J Coat Technol Res 11, 303–309 (2014). https://doi.org/10.1007/s11998-013-9535-x

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-013-9535-x