Abstract

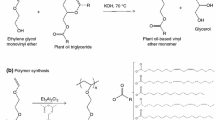

In this study, a process was developed to obtain vinylether-functional monomers containing fatty acid pendent groups directly from soybean oil (SBO) using base-catalyzed transesterification. In addition, a carbocationic polymerization process was developed for the vinylether monomers, which allowed for high molecular weight polymers to be produced without consuming any of the vinyl groups present in the fatty acid portion of the monomers. Compared to SBO, which possesses on average 4.5 vinyl groups per molecule, the polyvinylethers based on the soybean oil-derived vinylether monomers (polyVESFA) possess tens to thousands of vinyl groups per molecule depending on the polymer molecular weight produced. As a result of this difference, coatings based on polyVESFA were shown to possess much higher crosslink density at a given degree of functional group conversion compared with analogs based on conventional SBO. In addition, the dramatically higher number of functional groups per molecule associated with polyVESFA results in gel-points being reached at much lower functional group conversion, which was shown to dramatically reduce cure-time compared with SBO-based analogs. Based on the results obtained, it appears that these new renewable materials may have tremendous commercial utility in the coatings industry.

Similar content being viewed by others

References

Xu, Y, Hanna, MA, Isom, L, “Green Chemicals from Renewable Agricultural Biomass—A Mini Review.” Open Agric. J., 2 54–61 (2008)

Dodds, DR, Gross, RA, “Chemicals from Biomass.” Science, 318 1250–1251 (2007)

Meier, MAR, Metzger, JO, Schubert, US, “Plant Oil Renewable Resources as Green Alternatives in Polymer Science.” Chem. Soc. Rev., 36 1788–1802 (2007)

Gast, LE, Fatty Acids. AOCS Monograph 7, p. 564. American Oil Chemists’ Society, Champaign, IL, 1979

Derksen, JTP, Cuperus, FP, Kolster, P, “Renewable Resources in Coatings Technology: A Review.” Prog. Org. Coat., 27 45–53 (1996)

Solomon, DH, The Chemistry of Organic Film Formers, 2nd ed., pp. 36–37. Robert E. Krieger, Malabar, FL, 1982

Mallegol, J, Lemaire, J, Gardette, JL, “Drier Influence on the Curing of Linseed Oil.” Prog. Org. Coat., 39 107–113 (2000)

Mallegol, J, Gardette, JL, Lemaire, J, “Long-Term Behavior of Oil-Based Varnishes and Paints. I. Spectroscopic Analysis of Curing Drying Oils.” J. Am. Oil Chem. Soc., 76 967–976 (1999)

Mallegol, J, Gardette, JL, Lemaire, J, “Long-Term Behavior of Oil-Based Varnishes and Paints. Fate of Hydroperoxides in Drying Oils.” J. Am. Oil Chem. Soc., 77 249–255 (2000)

Mallegol, J, Gardette, JL, Lemaire, J, “Long-Term Behavior of Oil-Based Varnishes and Paints. Photo- and Thermooxidation of Cured Linseed Oil.” J. Am. Oil Chem. Soc., 77 257–263 (2000)

Baumann, H, Buhler, M, Fochem, H, Hirsinger, F, Zoebelein, H, Falbe, J, “Natural Fats and Oils—Renewable Raw Materials for the Chemical Industry.” Angew. Chem. Int. Ed. Engl., 27 41–62 (1988)

Liu, ZS, Erhan, SZ, Calvert, PD, “Solid Freeform Fabrication of Epoxidized Soybean Oil/Epoxy Composites with Di-, Tri-, and Polyethylene Amine Curing Agents.” J. Appl. Polym. Sci., 93 356–363 (2004)

Liu, ZS, Erhan, SZ, Xu, J, Calvert, PD, “Development Of Soybean Oil-Based Composites by Solid Freeform Fabrication Method: Epoxidized Soybean Oil with Bis or Polyalkyleneamine Curing Agents System.” J. Appl. Polym. Sci., 85 2100–2107 (2002)

Gerbase, AE, Petzhold, CL, Costa, APO, “Dynamic Mechanical and Thermal Behavior of Epoxy Resins Based on Soybean Oil.” J. Am. Oil Chem. Soc., 79 797–802 (2002)

Thames, SF, Yu, H, “Cationic UV-Cured Coatings of Epoxide-Containing Vegetable Oils.” Surf. Coat. Technol., 115 208–214 (1999)

Wan Rosli, WD, Kumar, RN, Mek Zah, S, Hilmi, MM, “UV Radiation Curing of Epoxidized Palm Oil-Cycloaliphatic Diepoxide System Induced by Cationic Photoinitiators for Surface Coatings.” Eur. Polym. J., 39 593–600 (2003)

Thames, SF, Yu, H, Subramanian, R, “Cationic Ultraviolet Curable Coatings from Castor Oil.” J. Appl. Polym. Sci., 77 8–13 (2000)

Bajpai, M, Shukla, V, Singh, DK, Singh, M, Shukla, R, “A Study of the Film Properties Of Pigmented UV-Curable Epoxidised Soybean Oil.” Pigm. Resin Technol., 33 160–164 (2004)

Dzunuzovic, E, Tasic, S, Bozic, B, Babic, D, Dunjic, B, “UV-Curable Hyperbranched Urethane Acrylate Oligomers Containing Soybean Fatty Acids.” Prog. Org. Coat., 52 136–143 (2005)

Zlatanic, A, Lava, C, Zhang, W, Petrovic, ZS, “Effect of Structure on Properties of Polyols and Polyurethanes Based on Different Vegetable Oils.” J. Polym. Sci., Part B: Polym. Phys., 42 809–819 (2004)

Javni, I, Zhang, W, Petrovic, ZS, “Effect of Different Isocyanates on the Properties of Soy-Based Polyurethanes.” J. Appl. Polym. Sci., 88 2912–2916 (2003)

Flory, PJ, Principles of Polymer Chemistry, pp. 347–398. Cornell University Press, Ithaca, NY, 1953

Aoshima, S, Higashimura, T, “Living Cationic Polymerization of Vinyl Monomers by Organoaluminum Halides. 3. Living Polymerization of Isobutyl Vinyl Ether by Ethyldichloroaluminum in the Presence of Ester Additives.” Macromolecules, 22 1009–1013 (1989)

Klaasen, RP, van der Leeuw, RPC, “Fast Drying Cobalt-Free High Solids Alkyd Paints.” Prog. Org. Coat., 55 149–153 (2006)

Dmytryshyn, SL, Dalai, AK, Chaudhari, ST, Mishra, HK, Reaney, MJ, “Synthesis and Characterization of Vegetable Oil Derived Esters: Evaluation for Their Diesel Additive Properties.” Bioresour. Technol., 92 55–64 (2004)

Ficek, B, Thiesen, AM, Scranton, AB, “Cationic Photopolymerizations of Thick Polymer Systems: Active Center Lifetime and Mobility.” Eur. Polym. J., 44 98–105 (2008)

Ito, H, Kidokoro, N, Ishikawa, H, “Differential Photocalorimetric Study of Cationic Photopolymerization.” J. Photopolym. Sci. Technol., 5 235–246 (1992)

Acknowledgment

The authors acknowledge the financial support received from the North Dakota Soybean Council.

Author information

Authors and Affiliations

Corresponding author

Additional information

This paper was awarded First Place in the John A. Gordon Best Paper competition at the 2011 CoatingsTech Conference, sponsored by ACA, on March 14–16, 2011 in Rosemont, IL.

An erratum to this article can be found at http://dx.doi.org/10.1007/s11998-012-9399-5.

Rights and permissions

About this article

Cite this article

Alam, S., Chisholm, B.J. Coatings derived from novel, soybean oil-based polymers produced using carbocationic polymerization. J Coat Technol Res 8, 671–683 (2011). https://doi.org/10.1007/s11998-011-9360-z

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-011-9360-z