Abstract

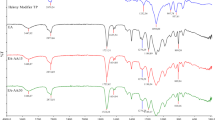

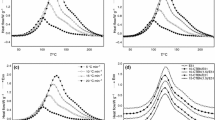

Blend samples of cardanol-based epoxidized novolac resin and different weight percentages of carboxyl-terminated butadiene acrylonitrile (CTBN) were developed and cured with stoichiometric amounts of aliphatic amine. The formation of various products during the curing of blend samples has been studied by Fourier-transform infrared spectroscopy. The dynamic differential scanning calorimeter scans showed that the pure epoxies and their blend samples with CTBN cured in the temperature range of 100–150°C. The blend sample containing 15 wt% CTBN showed the least cure time (at 120°C) among all other blend samples. Upon evaluation, it was found that blend samples exhibit better properties compared to pure epoxy resin in terms of increase in impact strength and elongation-at-break of the casting and gloss, scratch hardness, adhesion, and flexibility of the film. The improvement in these properties indicates that the rubber modified resin would be more durable than the epoxy based on cardanol. Chemical and morphological properties of the formulated resins were also determined. The thermal stability of the blend samples containing 15 wt% CTBN in epoxy resin was the highest among all other prepared systems. The blend morphology, studied by scanning electron microscope, showed the presence of precipitated discrete rubber particles, which dispersed throughout the epoxy matrix—i.e., they revealed the presence of two-phase morphological features.

Similar content being viewed by others

References

Menon, ARR, Pillai, CKS, Sudha, JD, Mathew, AG, “Cashew Nut Shell Liquid—Its Polymeric and Other Industrial Products.” J. Sci. Ind. Res., 44 324–338 (1985)

Tyman, JHP, Synthetic and Natural Phenols Studies in Organic Chemistry, Vol. 52, p. 518. Elsevier, Amsterdam (1975)

Pillai, CKS, Prasad, VS, Sudha, JD, Bera, SC, Menon, ARR, “Polymeric Resins from Renewable Resources II Synthesis and Characterization of Flame Retardant Prepolymer from Cardanol.” J. Appl. Polym. Sci., 41 2487–2501 (1990)

Nimuru, N, Miyakoshi, T, “Structural Characterization of Cashew Resin Film Using Two-Stage Pyrolysis-Gas Chromatography/Mass Spectrometry.” Int. J. Polym. Anal. Charact., 8 47–66 (2003)

Bender, HL, Farnham, AG, Guyer, JW, “Crystalline Dehydroxy Phenols.” US Patent 2,464,207, 1949

Jayabalan, M, Rajadurai, S, “A Study on the Utilization of CNSL for the Development of Fast Curing Resins and Glass Fabric Laminates.” Pop. Plast., 30 30–35 (1985)

Panasare, V, Kulkarni, A, “Azo Dyes from Cashew Nut Shell Liquid Derivatives.” J. Ind. Chem. Soc., 41 251–255 (1964)

Kinloch, AJ, Reiw, CK, Rubber-Toughened Plastics. Advances in Chemistry Series 22, p. 67. American Chemical Society, Washington, DC (1989)

Kinloch, AJ, Young, RJ, Fracture Behaviour of Polymers. Applied Science, London (1983)

Huang, J, Kinloch, AJ, “The Toughness of Epoxy Polymer Containing Micro Voids.” Polymer, 33 1330–1332 (1992)

Yadav, R, Srivastava, D, “Kinetics of the Acid–Catalyzed Cardanol–Formaldehyde Reactions.” Mater. Chem. Phys., 106 74–81 (2007)

Devi, A, Srivastava, D, “Studies on the Blends of Cardanol-Based Epoxidized Novolac Type Phenolic Resin and Carboxyl Terminated Polybutadiene (CTPB) I.” Mater. Sci. Eng. A, 458 336–347 (2007)

Ting, RY, Elastomer Modified Epoxy Resins, Chemistry and Technology, 2nd ed., pp. 561–601. Marcel Dekker, New York (1988)

Lee, H, Neville, K (eds.), Hand Book of Epoxy Resins. McGraw-Hill, New York (1982)

Evtushenko, YuM, Jvanov, VM, Zaitsev, BE, “Determination of Epoxide and Hydroxyl Groups in Epoxide Resins by IR Spectrometry.” J. Anal. Chem., 58 347–350 (2003)

Smith, A, Applied Infrared Spectroscopy. Wiley, New York (1979) (translated under the title prikladnaya Ik-Spektroscopiya. Mir, Moscow, 1982)

Nigam, V, Setua, DK, Mathur, GN, “Wide-Angle X-Ray Scattering, Fourier Transform Infrared Spectroscopy and Scanning Electron Microscopy Studies on the Influence of the Addition of Liquid Functional Rubber into Epoxy Thermoset.” J. Appl. Polym. Sci., 70 537–543 (1998)

Ramos, VD, da Costa, HM, Soares, VLP, Nascimento, RSV, “Hybrid Composites of Epoxy Resin Modified with Carboxyl Terminated Butadiene Acrylonitrile Copolymer and Fly Ash Micro Spheres.” Polym. Test., 24 219–226 (2005)

Horie, K, Hiura, H, Sawada, M, Mita, I, Kambe, H, “Calorimetric Investigation of Polymerization Reactions. III. Curing Reaction of Epoxide with Amines.” J. Polym. Sci. A-1, 8 1357–1372 (1970)

Smith, IT, “The Mechanism of the Crosslinking of Epoxide Resins by Amines.” Polymer, 2 95–108 (1961)

Rozenberg, BA, “Kinetics, Thermodynamics and Mechanism of Reactions of Epoxy Oligomers with Amines.” Adv. Polym. Sci., 75 113–165 (1985)

Aijuan, Gu, Guozheng, L, “Thermal Stability and Kinetics Analysis of Rubber Modified Epoxy Resin by High Resolution Thermo Gravimetric Analysis.” J. Appl. Polym. Sci., 89 359–360 (2003)

Yang, WF, We, YZ, “A Study on the Toughening Mechanism of Rubber-Modified Polyfunctional Epoxy Resins.” Mater. Chem. Phys., 15 505–510 (1986)

Wise, CW, Cook, WD, Goodwin, AA, “CTBN Rubber Phase Precipitation in Model Epoxy Resins.” Polymer, 41 4625–4633 (2000)

Calabrese, L, Valenza, A, “The Effect of a Liquid CTBN Rubber Modifier on the Thermo-Kinetic Parameters of an Epoxy Resin During a Pultrusion Process.” Compos. Sci. Technol., 63 851–860 (2003)

Nigam, V, Saraf, MN, Mathur, GN, “Cure Characterization of Rubber Modified Epoxy Novolacs.” J. Therm. Anal., 49 483–490 (1997)

Kushenbaum, SL, Bell, JP, “Matrix Viscoelasticity: Controlling Factor in the Rubber Toughening of Epoxy Resins.” J. Appl. Polym. Sci., 30 1875–1891 (1985)

Manzione, LT, Gillham, JK, “Rubber-Modified Epoxies. II. Morphology and Mechanical Properties.” J. Appl. Polym. Sci., 26 907–919 (1981)

Ratana, D, Banthia, AK, Deb, PC, “Acrylate-Based Liquid Rubber as Impact Modifier for Epoxy Resin.” J. Appl. Polym. Sci., 80 1792–1801 (2001)

Latha, PB, Adhinaryanan, K, Ramaswamy, R, “Epoxidized Hydroxy-Terminated Polybutadiene-Synthesis, Characterization and Toughening Studies.” Int. J. Adhes. Adhes., 14 57–61 (1994)

Maity, T, Samanta, BC, Dalai, S, Banthia, AK, “Curing Study of Epoxy Resin by New Aromatic Amine Functional Curing Agents along with Mechanical and Thermal Evaluations.” Mater. Sci. Eng. A, 464 38–46 (2007)

Kaji, M, Nakahara, K, Endo, T, “Synthesis of a Bifunctional Epoxy Monomer Containing Biphenyl Moiety and Properties of Its Cured Polymer with Phenol Novolac.” J. Appl. Polym. Sci., 74 690–698 (1999)

Menon, ARR, Agibodion, AI, Pillai, CKS, Mathew, AG, Bhagawan, SS, “Processability, Characterization and Physico-Mechanical Properties of Natural Rubber Modifier with CNSL and CNSL-Formaldehyde Resin.” Eur. Polym. J., 38 163–168 (2002)

Chan, LC, Gillham, JK, Kinloch, AJ, Shaw, SJ, “Rubber-Modified Epoxies.” In: Riew, CK, Gillham, JK (eds.) Morphology, Transitions and Mechanical Properties, Chapter 16, Vol. Adv. Chem. Ser. 208, pp. 261–279. American Chemical Society, Washington, DC (1984)

Douglass, SK, Beaumont, PWR, Ashby, MF, “A Model for the Toughness of Epoxy-Rubber Particulate Composites.” J. Mater. Sci., 15 1109–1123 (1980)

Sue, HJ, Garciameitin, EI, Pickelman, DM, “Fracture Behavior of Rubber Modified High Performance Epoxies.” In: Arends, CB (ed.) Polymer Toughening, pp. 131–173. Marcel Dekker, New York (1996)

Barton, JM, “Monitoring the Cross-Linking of Epoxide Resins by Thermo Analytical Techniques.” J. Macromol. Sci. A, 8 25–32 (1974)

Acknowledgments

This work was sponsored by Council of Science and Technology, Lucknow, UP, India. We also thankfully acknowledge the contributions rendered by M/s Satya Cashew Pvt. Ltd., Chennai, for providing cardanol, and M/s Emerald Performance Materials, LLC, Hong Kong, for providing CTBN.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Yadav, R., Srivastava, D. Blends of cardanol-based epoxidized novolac resin and CTBN for application in surface coating: a study on thermal, mechanical, chemical, and morphological characteristics. J Coat Technol Res 7, 557–568 (2010). https://doi.org/10.1007/s11998-009-9235-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11998-009-9235-8