Abstract

Pasta, a staple food worldwide consumed, was fortified with maqui (Aristotelia chilensis) berry powder (MBP) and the effect of MBP inclusion was evaluated concerning technological, nutritional, and sensory properties. Fresh pasta samples were formulated by replacing 0, 7.5, and 15 g 100 g−1 of durum wheat semolina with MBP. The inclusion of MBP did not affect the moisture content, but the water activity decreased in the fortified samples, while pH values decreased with increasing MBP levels in the recipe. The pasta fully cooking time and the swelling index were reduced, while the cooking loss and the firmness increased with increasing MBP levels. In addition, MBP increased the total dietary fiber, ash, and phenol contents, along with the in vitro antioxidant activities. The starch hydrolysis index and the predicted glycemic index of cooked fresh pasta decreased along with the increase of MBP addition. The MPB addition to fresh pasta could represent a valuable strategy for increasing its nutritional value, maintaining pasta’s technological properties without affecting the sensory acceptability.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

The interest in producing high-quality and highly nutritious cereal-based foods is increasing. To this end, several functional vegetal ingredients with potential beneficial effects have been incorporated in different foods, aiming to enhance their nutritional profile (Wang et al., 2021).

Among the different ingredients, maqui (Aristotelia chilensis (Mol.) Stuntz) is an endemic species of the sub-Antarctic forests of Chile that produces small edible purple/blackberries. Pharmacologically, fruits and leaves of maqui have been investigated for anti-inflammatory, analgesic, antioxidant, antidiabetic, antiviral, and antimicrobial activities (Misle et al., 2011). The maqui fruits contain high levels of anthocyanins, mainly delphinidin, malvidin, petunidin, cyanidin, and peonidin. Thanks to the high level of bioactive compounds with antioxidant activity, like polyphenols including flavonoids, condensed tannins, and phenolic acids, it is considered a “superfruit” (Zúñiga et al., 2017). Several epidemiological studies on human health underlined the beneficial role of phenolic compounds in the prevention of cardiovascular diseases, diabetes, and cancers (Cao et al., 2019; Rodríguez Montealegre et al., 2006; Rothwell et al., 2017). Beyond the health benefits that could be provided by including maqui berries in the diet, this fruit, like other berries, has a concise shelf life (2–3 days at room temperature and 5–10 days under refrigeration), thus affecting its consumption (Bustos et al., 2020). This fact encourages the development of products like jams, powders, and concentrates with a longer shelf-life to be used in foods acting as a vehicle for bioactive compounds (Bianchi et al., 2021a; Cisneros-Yupanqui et al., 2020; Rainero et al., 2021; Simonato et al., 2019, 2020).

Durum wheat pasta consumption is increasing globally, thus making this staple food a potential vehicle to deliver functional ingredients (Bianchi, et al., 2021b; Wang et al., 2021). Traditional wheat durum pasta is generally rich in carbohydrates, especially in starch, but relatively poor in other nutrients, including dietary fiber, thus representing an ideal target for functionalization. Accordingly, several attempts have been reported in the literature concerning the incorporation of functional vegetable ingredients into pasta, including, but not limited to, pigmented cereals, legumes, and various origin ingredients showing interesting results in terms of nutritional, technological, and overall sensory attributes (Bianchi, et al., 2021b; Simonato et al., 2019; Wang et al., 2021). In addition, certain ingredients used in pasta formulation have proven the potential to further modulate the starch digestibility, at least in vitro, thus providing a two-pronged approach to improving the nutritional profile of this food product (Rocchetti et al., 2020, 2021). Jeon & Lee (2021) have studied the addition of maqui berries in cookies. Fortified cookies showed acceptable physical characteristics, improved antioxidant activities, and satisfactory sensory scores (Jeon & Lee, 2021).

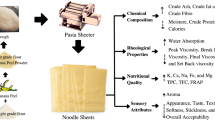

However, to the best of our knowledge, this is the first work that performs maqui berry powder (MBP) as an ingredient in durum wheat fresh pasta. This study aimed to evaluate the suitability of MBP incorporation in wheat-based pasta formulation by examining the products’ cooking properties, color, and texture. From a nutritional point of view, the effect of MBP was evaluated on the phenolic content and the in vitro antioxidant activity, including their maintenance during pasta cooking. In addition, we considered the impact of MBP fortification on starch digestibility. Lastly, the newly formulated pasta experienced a sensory analysis.

Materials and Methods

Maqui Fresh Pasta Preparation

Durum wheat semolina (WS) (Molino Rosso, Italia, 2020 production) and organic MBP (Erbavoglio, Italy, 2020 production) were commercially purchased. The WS and MBP contained 72.1 and 48.9 g 100 g−1 total carbohydrates, 11.3 and 6.8 g 100 g−1 crude proteins, 1.0 and 9.4 g 100 g−1 total fat, and 3.7 and 26.7 g 100 g−1 total dietary fiber, respectively, as reported in the label.

Experimental fresh pasta samples were formulated by substituting 0, 7.5, and 15 g 100 g−1 of WS with MBP, giving PM0 (control), PM7.5, and PM15 samples, respectively. The dough contained 35% v/w of tap water (37 °C) and samples of fresh pasta were obtained after extrusion with a professional pasta maker machine through a 0.22-cm diameter bronze spaghetti die (Mod. Lillodue, Bottene, Marano Vicentino, Italy) and cut when reached 25 cm length. For each recipe, three pasta batches were produced following the procedure detailed by Rocchetti et al. (2020) (Rocchetti et al., 2020). Pasta samples were cooked in distilled water in a 1:10 (w/v) ratio.

Technological Properties

The moisture content, the fully cooked time (FCT), and the cooking loss (CL) of fresh pasta were determined using the AACC methods 44-15A, 66–51.01, and 66–50 (AACC, 2000). The swelling index (SI) was determined following the procedure reported by Clearly and Brennan (2006). The water activity (aw) was measured using a Hygropalm HC2-AWmeter (Rotronic Italia, Milano) at 23 °C, as reported in Rainero et al. (2021).

Texture Analysis

A TA-XT2i Texture Analyzer (Stable Micro Systems, UK) equipped with a 5-kg load cell was used. After cooking in deionized water, samples were dipped in cool deionized water for 45 s to stop the cooking process. Pasta firmness, defined as maximum cutting force (AACC method 16–50; AACC 2000) (AACC, 2000), was measured with a light knife blade (A/LKB) and a speed of 0.17 mm s−1. The adhesiveness was measured following the procedure detailed by Murray et al. (2018). Ten measurements were done for each sample.

Color Analysis

The surface color of samples before and after the cooking was measured by a reflectance colorimeter (Illuminant D65) (Minolta Chroma meter CR-300, Osaka, Japan) based on the color system CIE – L* a* b*. Analyses were performed at ten different points of each pasta sample. Minolta Eqs. (1) and (2) were used to calculate the total color difference (ΔE), respectively:

where L, L0, a, a0, b, and b0 are the measured values of pasta fortified with MBP or the control pasta.

Proximate Composition of Pasta

The chemical composition of raw fresh pasta was performed according to AOAC for dry matter (DM; method 930.15), ash (method 942.05), crude protein (method 976.05), crude lipid (method 954.02 without acid hydrolysis), total starch (method 996.11, using thermostable α-amylase) (Megazyme cat. no. E-BSTAA), and amyloglucosidase (Megazyme cat. no. E-AMGDF). The total soluble and insoluble dietary fiber contents (TDF, SDF, IDF, respectively) were determined according to the AOAC method 991.43 (AOAC, 2007). Free sugars were assessed using the Megazyme assay kit K-SUFRG 06/14 (Megazyme, Wicklow, Ireland). Batches were analyzed in triplicate.

Determination of Total Phenolic Compounds, Monomeric Anthocyanin Content, ABTS, and FRAP Assay

Cooked and uncooked pasta samples were freeze-dried, finely ground (Moulinex AR1108, Moulinex, Milan, Italy), and sieved (200 µm) (Simonato et al., 2019, 2020). Five hundred milligrams of each powdered sample was extracted for 16 h with 7.5 mL of MeOH/HCl 97:3 (v/v), with stirring, in the dark, at room temperature. After centrifugation (3500 × g for 10 min at room temperature), supernatants were collected for the determination of the total phenol compounds (TPC) by Folin–Ciocalteau assay, for ABTS (2,20-azino-bis (3-ethylbenzothiazoline-6-sulfonic acid)) and FRAP (ferric reducing ability of plasma) radical scavenging activities determination. TPC, FRAP, and ABTS measurements were made as described by Tolve et al. (2020) (Tolve et al., 2021). The monomeric anthocyanins content (MAC) followed pH differential method AOAC 200.02 (AOAC, 2007). Anthocyanin content has been expressed as mg of cyanidin-3-glucoside equivalent (CE).

In Vitro Starch Digestion and Starch Fractions of Cooked Pasta Samples

Samples were in vitro digested after cooking using a 3-step multi-enzymatic in vitro starch digestion protocol with minor modifications (Giuberti et al., 2015; Rocchetti et al., 2019). Cooked pasta samples were minced by an electric meat mincer to simulate mastication (Rocchetti et al., 2020), weighed (500 mg of total starch), and suspended in a solution containing α-amylase (5 mg mL−1; A3176, Sigma-Aldrich® Co., Milan, Italy) at 37 °C under gentle agitation for the oral digestion phase. After 3 min of incubation, a 0.05 M HCl solution containing pepsin (5 mg mL−1; P-7000, Sigma-Aldrich® Co., Milan, Italy) was added to mimic the gastric digestion phase. After 60 min, the solution pH was adjusted to 5.2 with a 0.1-M sodium acetate buffer, and an enzyme mixture mimicking the pancreatic digestion phase (with an amylase activity of about 7000 U mL−1) was added (Giuberti et al., 2015). Aliquots were carefully taken at 0 (before the addition of the enzyme mixture) and every 30 min up to 180 min after the enzyme addition and mixed with absolute ethanol. The amount of released glucose was determined with a glucose oxidase kit (GODPOD 4058, Giesse Diagnostic s.n.c., Rome, Italy; factor of 0.9). The absorbance values were then plotted on a graph vs. time, and the area under the hydrolysis curve (AUHC; 0–180 min) was measured using the trapezoid rule. The starch hydrolysis index (HI) value was calculated as the AUHC with the product as a percentage of the corresponding area using commercial fresh white wheat bread over the same period. Analyses were run in triplicate on each pasta batch. From the HI, a predicted glycemic index (pGI) was determined with the formula of Granfeldt et al. (1992) (pGI = 8.198 + 0.862 × HI).

The rapidly digestible starch (RDS) and slowly digestible starch (SDS) were measured following the Englyst method (Englyst et al., 1992) slightly modified by Simonato et al. (2019). The resistant starch (RS) content was quantified using a commercial K-RSTAR assay kit (Megazyme, Wicklow, Ireland).

Sensory Evaluation

The sensory profile of FCT pasta samples was carried out by a panel of 21 judges (11 men, 10 women; 22–64 years old) recruited from students and staff of the Università Cattolica del Sacro Cuore. Each member was trained prior to the test. The judges were trained to recognize and assign an intensity score to 12 sensory attributes (i.e., pasta and berry odor, color uniformity, and roughness for the appearance; overall flavor, berry flavor, sweetness, and acidity for the taste; gumminess, adhesiveness, grittiness, and elasticity for the texture). A scale whose score ranges from 1 for the lowest intensity to 9, the highest intensity, was used to define the intensity of the descriptors. Each judge received 15 g of cooked pasta placed in a covered container and served in random and balanced order. After sample testing, panelists cleansed their palates with tap water. In addition, the judges gave an opinion on the overall acceptability of pasta using a nine-point hedonic scale (1 = dislike extremely; 9 = like extremely). Pasta samples were considered acceptable if their mean scores for overall acceptability were above 5 (neither like nor dislike).

Statistical Analysis

The analyses were carried out at least in triplicate. All data represent the means of at least three measurements and results are expressed as the mean values ± standard deviation. The comparison of means was conducted using the analysis of variance (ANOVA) with a post hoc Tukey test at p < 0.05. Statistical analyses were performed by XLSTAT (Addinsoft SARL, Paris, France).

Results and Discussion

Proximate Analyses

The chemical composition of pasta fortified with different levels of MBP in the recipe is reported in Table 1. The substitution of WF with increasing levels of MBP influenced most of the selected chemical parameters. In particular, the PM15 was characterized by the highest TDF content (i.e., 8.34 g 100 g−1 DM.; p < 0.05). These changes are strictly related to the MBP composition, which contains a significant amount of dietary fiber. The PM15 pasta sample can be therefore claimed as a “high fibers content” food product, being the TDF higher than 6 g 100 g−1, while MP7.5 pasta as a “source of fiber” since the TDF was greater than 3 g 100 g−1 (European Parliament, 2006). Furthermore, the IDF represented the most relevant portion of TDF in MBP-fortified wheat-based pasta, accounting for about 75% of the TDF content. In addition, the MBP inclusion in pasta formulation caused an increase in ash (from 0.71 to 1.19 g 100 g−1 DM for PM0 and PM15, respectively; p < 0.05), as a function of the macro-and micro-elements contained in MBP. Moreover, glucose, fructose, and fat contents increased (p < 0.05), while the total starch decreased (p < 0.05) in MBP pasta samples when compared to the control. Comparable results have been reported in black currant and jostaberry powder–enriched biscuits (Molnar et al., 2015).

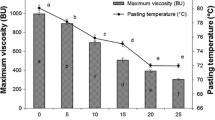

Technological and Cooking Properties of Pasta

The MBP level in the recipe affected the selected technological and cooking properties of fresh pasta (Table 2). In particular, fresh pasta had to comply with the limits allowed by the law of aw (0.92–0.97) and moisture content (> 24%) (Simonato et al., 2020). All pasta samples in the current study fall within these legal limits. The MBP fortification did not affect the moisture content of pasta, with a final average content of 29.79 g water 100 g−1 pasta. On the contrary, water activity decreased (p < 0.05) in MBP-fortified samples when compared to the control. As referred by Littardi et al. (2020), this could be due to a stronger water-protein interaction or due to the higher dietary fiber content of the MBP-fortified samples. The pH values decreased (p < 0.05) upon the addition of MBP in the recipe, ranging from 6.32 to 4.73 for PM0 and PM15, respectively, due to the strongly acidic nature of MBP ingredient, typical of fruits (Bianchi, et al., 2021b; Jeon & Lee, 2021). A similar reduction in pH has been reported in cookies formulated with increasing amounts (up to 10% w/w) of MBP in the recipe (Jeon & Lee, 2021).

An important parameter to control the technological quality of the pasta is the amount of solid loss in the cooking water. The cooking water of pasta may become cloudy mainly after the solubilization of the starch fraction. Non-starchy polysaccharides can also be lost by leaching (Aravind et al., 2012). In our experimental conditions, the PM15 sample was characterized by the highest cooking loss, being 10.5%. However, this value of solid loss can be considered acceptable for the production of fresh durum wheat-based pasta, being lower than the threshold value of 12% for fresh pasta (Sant’Anna et al., 2014). The higher cooking loss characterizing PM15 could be related to the level of TDF in the sample, which can contribute to weaken the pasta gluten network, causing less solid retention and thus higher leaching of components in the cooking water (Bianchi, et al., 2021b). Accordingly, Bustos et al. (2019) reported a higher cooking loss in pasta samples enriched with 2.5 and 7.5 g 100 g−1 with different berry compared to the control (Bustos et al., 2019). In addition, the inclusion of fiber in a pasta blend can cause structural modifications to different extents, allowing quicker water penetration on cooking. This can affect the starch gelatinization, thus justifying the reduction in the FCT, in line with previous findings (Bustos et al., 2019). A similar trend has already been reported in pasta formulated with increasing amounts of grape pomace in the recipe (Gaita et al., 2020; Tolve et al., 2020), with Eikorn brewer’s spent grain (Nocente et al., 2019), apple pomace (Lončarić et al., 2014), with olive pomace (Simonato et al., 2019), and orange by-product (Crizel et al., 2015). The SI decreased in PM15 compared to PM0 and PM7.5 samples. Similar trends were reported by Aravind et al. (2012), and Simonato et al. (2019) (Aravind et al., 2012; Simonato et al., 2020). Moreover, Bustos et al. (2019) reported that air-dried berry pasta had lower SI compared to control pasta (Bustos et al., 2019). The reduction in SI could be attributed to water competition between fiber and starch (Aravind et al., 2012; Simonato et al., 2020; Tolve et al., 2020).

The textural characteristics of pasta can play a crucial role in determining the final acceptance by consumers, showing a preference for pasta that retains texture characteristics following cooking. As the substitution level of WS by MBP increased, the firmness of samples cooked to FCT increased (p < 0.05). It is well-known that incorporating fiber, whether soluble or insoluble, in wheat-based pasta can lead to changes in the texture properties of the final products (Sissons, 2022). Following incorporating a high-fiber ingredient, firmness is expected to decline due to the interaction with the gluten network (Bustos et al., 2019). However, as a function of the selected fiber-rich ingredients, several studies have reported opposed results, indicating an increase in pasta firmness (Rakhesh et al., 2015; Tolve et al., 2020). These discrepancies are likely to be related to differences in pasta-making methods and the fiber type in the formulation. In addition, one of the possible explanations leading to a greater value of firmness can be the competition of the selected fiber ingredient with starch for water; as the MBP reduced the swelling index (p < 0.05), this would have contributed to making the pasta firmer, as observed by other authors (Rakhesh et al., 2015).

Adhesiveness also increased in the PM7.5 and PM15 samples with respect to control pasta, in line with previous findings (Tolve et al., 2020). This could be related to the breaking of the continuous structure of the pasta after inclusion of a given fiber-rich ingredient (Kim et al., 2017). In addition, fiber components, modifying the pasta structure, can increase the sample adhesiveness because of the starch leaching, in agreement with the increase in the cooking loss (Tolve et al., 2020).

Color Analysis

The color of pasta, even in the uncooked and cooked forms, was influenced by the addition of MBP in the recipe (Table 3) (Fig. 1). In particular, L* and b* parameters decreased (p < 0.05), while a* value increased (p < 0.05) as the level of MBP increased in the recipe. Similar results were shown in cookies formulated with an increasing amount of MBP in the recipe (Jeon & Lee, 2021). In particular, the authors reported that as the level of MBP in the formulation increased, the cookies became darker and browner in color (i.e., lower L* value) while the a* value increased (Jeon & Lee, 2021). Furthermore, cooked MBP-containing pasta tends to lose brightness (i.e., L*), compared to the raw counterpart. This is mainly due to the loss of MBP pigments during the cooking phase, in line with previous findings (Tolve et al., 2020).

TPC, FRAP, ABTS Assays, and MAC

The addition of MBP in the pasta recipe increased TPC by 750% in PM7.5 and 1272% in PM15 cooked samples with respect to control pasta (Table 4). The FRAP increased with the level of MBP fortification and between cooked and raw samples (except for control pasta). The substitution of semolina with 7.5 and 15% of MP in the formulation enhanced the antioxidant activities detected with FRAP of cooked samples of about 2330 and 6119%, respectively. The ABTS had a similar trend with the FRAP assays, but the cooked PM15 sample did not differ statistically from raw samples. Overall, two-way ANOVA confirmed that the cooking process affected all antioxidant contents (p < 0.05). Indeed, as reported in the literature, the reduction of TPC in cooked pasta could happen due to the degradation of polyphenols during the boiling treatment and/or to the leaching of some polyphenols (mainly from the free fraction) into the cooking water (Bianchi, et al., 2021b; Simonato et al., 2019; Tolve et al., 2020). Despite this loss, all cooked pasta samples with MBP still had a greater (p < 0.05) antioxidant capacity compared to the control PM0. The MAC in MBP-fortified pasta statistically increased from the raw to cooked sample and approximately improved anthocyanin content in cooked PM15 of 57-fold.

Considering a raw pasta serving of 80 g, current data indicated that with PM15, the TPC intake is about 1040 mg of gallic acid equivalent and 290 mg of cyanidin-3-glucoside equivalent. The antioxidant activities were positively correlated with TPC and MAC according to the data reported for both ABTS (r = 0.99) and the FRAP assays (r = 0.97) in cooked samples. A similar trend was also observed for olive pomace– and grape pomace–fortified pasta (Simonato et al., 2019; Tolve et al., 2020).

In Vitro Starch Digestion and Predicted Glycemic Index

Cooked pasta samples were evaluated in terms of in vitro starch digestibility to explore the role of MBP addition on the nutritional important starch fractions (i.e., RDS, SDS, and RS) and on the overall in vitro starch digestion. Starch can be classified into three main categories as a function of the rate and extent of in vitro digestion. The first two include RDS and SDS fractions, which are completely digested in the small intestine with different rates (Englyst et al., 1992). Nutritional indications suggested that the RDS is the starch fraction that causes a rapid increase of plasma glucose and insulin levels after ingestion, whereas the SDS fraction is degraded completely, but more slowly by human digestive enzymes, thus resulting in reduced postprandial glucose and insulin response (Lehmann & Robin, 2007). The third category defined as RS is referred to that fraction of starch not enzymatically degraded in the small intestine but fermented in the large intestine (Fuentes-Zaragoza et al., 2011). Several functional and health benefits are associated with RS consumption, including hypoglycemic effects, prevention of colorectal cancer, and lower plasma cholesterol and triglyceride concentrations (Birt et al., 2013). In addition, there is growing interest in predicting the likely in vivo glucose response of food of interest (i.e., glycemic index) using vitro digestion methods, especially for the screening processes occurring during the development of a new food product, as a precursive method to in vivo measurements (Argyri et al., 2016).

The addition of MBP in the recipe affected the in vitro starch digestion of samples (Table 5). In particular, the PM7.5 and PM15 samples, compared to the PM0 control sample, showed a decrease in RDS (19.70 and 16.48 g 100 g−1 food product for PM7.5 and PM15 versus 22.74 g 100 g−1 food product for PM0, respectively; p < 0.05) and an increase in SDS (21.23 and 21.75 g 100 g−1 food product for PM7.5 and PM15 versus 20.37 g 100 g−1 food product for PM0, respectively; p < 0.05) and in RS contents (1.03 and 1.09 g 100 g−1 food product for PM7.5 and PM15 versus 0.69 g 100 g−1 food product for PM0, respectively; p < 0.05). Similar results have been previously reported in biscuits formulated with different berry powders in the recipe (Molnar et al., 2015). In addition, the starch HI decreased at higher MBP inclusion levels, ranging from 57.92 to 52.11 and 49.65 for PM0, PM7.5, and PM15, respectively (p < 0.05). Therefore, the calculated pGI values were 58.13, 53.12, and 50.99 for PM0, PM7.5, and PM15, respectively (p < 0.05). Being the in vivo glycemic index values below the threshold of 55, the newly formulated MBP-pasta might be considered a low glycemic index food product, even if in vivo trials are strongly warranted to confirm current in vitro results.

The lower in vitro starch digestibility of MBP-fresh pasta can be attributed to several factors, including the changes in the chemical composition following the MBP addition and to potential interactions among different food components and starch-hydrolyzing enzymes (Sun & Miao, 2020; Tian & Sun, 2020). The increase in the dietary fiber content can have influenced the in vitro starch digestibility of samples through starch granule encapsulation, thus limiting the access to amylolytic enzymes, in line with previous findings (Garcia-Valle et al., 2021). In addition, the more rigid texture (i.e., greater firmness) of PM7.5 and PM15 as compared to PM0 could have decreased the in vitro starch digestion of MBP-added samples, being recognized the role of the physical texture of the food in modulating the in vitro starch digestion (Singh et al., 2010). This appeared in line with previous findings (Alam et al., 2019; Rocchetti et al., 2021). Lastly, the higher anthocyanin content characterizing the MBP-added pasta can also have played a role in modulating the in vitro starch digestibility of cooked samples through two possible mechanisms: as inhibitors of starch-hydrolyzing enzymes and/or by interacting with the amylose chains, contributing to the creation of complex structures with limited access to the enzymatic attack itself (Giuberti et al., 2020).

Sensory Analysis

As a final analysis of pasta samples, a quantitative descriptive analysis was performed to observe changes in sensory characteristics following maqui fortification. The inclusion of MBP in doughs has led to a variation in the sensory attributes of the samples (Fig. 2). As for the aromatic part of the analysis, the pasta and berry odor showed a reverse behavior because of maqui fortification. Indeed, in the fortified pasta, the berry’s odor prevailed significantly over the control sample, where the odor of pasta was perceived the most.

The PM0 exhibited more color uniformity than PM7.5 and PM15, which scored similarly. Roughness and the overall flavor were not modified by the addition of maqui in the pasta. While, regarding the taste, the sweetness and berry flavor were more perceptible in the fortified pasta. In addition, the acidity taste increased in PM7.5 and PM15, but without substantial differences between them. The tactile sensations and consistency of the samples were modified by maqui fortification. The attributes most influenced by the fortification process were the grittiness and elasticity of pasta samples. The overall acceptability value of the PM15 being 5.3 was lower than the control one but overcame the threshold value of 5. MP0 sample had the best acceptability by the panel with a score of 6.8, and PM7.5 recorded a mean score of 6.0 and did not differ statistically from the control sample.

Conclusion

The MBP has potential application as a value-added ingredient to produce fresh pasta with higher total dietary fiber content. The replacement of durum wheat semolina with increasing levels of MBP resulted in shorter cooking time, higher firmness, and adhesiveness. The lightness of uncooked and cooked pasta decreased as the level of MBP increased in the recipe, which may reduce the attractiveness of the newly formulated pasta to consumers. The fortified pasta received good sensory feedback from the panel with a score of acceptance superior to the threshold of acceptability. PM 7.5 and P15 benefit from the “source of fiber” or “high in fiber” claim, respectively. The predicted glycemic index values classified PM7.5 and PM15 as low glycemic index pasta, giving valuable results in terms of starch digestibility of the products. In addition, the experimental pasta proposed in this study has a good content of polyphenols such as anthocyanins and antioxidant capacity. The results reported highlight that MBP could represent a valuable and novel ingredient in the formulation of functional pasta.

Availability of Data and Materials

Not applicable.

References

AACC. (2000). Approved methods of the American Association of Cereal Chemists, 10th edn. The Association: St. Paul, MN.

Alam, S. A., Pentikäinen, S., Närväinen, J., Katina, K., Poutanen, K., & Sozer, N. (2019). The effect of structure and texture on the breakdown pattern during mastication and impacts on in vitro starch digestibility of high fibre rye extrudates. Food & Function, 10, 1958–1973.

AOAC. (2007). Official methods of analysis of AOAC International, 18th edn. AOAC International, Gaithersburg

Aravind, N., Sissons, M., Egan, N., & Fellows, C. (2012). Effect of insoluble dietary fibre addition on technological, sensory, and structural properties of durum wheat spaghetti. Food Chemistry, 130, 299–309.

Argyri, K., Athanasatou, A., Bouga, M., & Kapsokefalou, M. (2016). The potential of an in vitro digestion method for predicting glycemic response of foods and meals. Nutrients, 8(4), 209. https://doi.org/10.3390/nu8040209

Bianchi, F., Lomuscio, E., Rizzi, C., & Simonato, B. (2021a). Capacity of breadsticks fortified with grape pomace powders. Foods, 10(11), 2815. https://doi.org/10.3390/foods10112815

Bianchi, F., Tolve, R., Rainero, G., Bordiga, M., Brennan, C. S., & Simonato, B. (2021b). Technological, nutritional, and sensory properties of pasta fortified with agro‐industrial by‐products: A review. International Journal Food Science Technolology, 0–3.

Birt, D. F., Boylston, T., Hendrich, S., et al. (2013). Resistant starch: Promise for improving human health. Advances in Nutrition, 4, 587–601.

Bustos, M. C., Paesani, C., Quiroga, F., & León, A. E. (2019). Technological and sensorial quality of berry-enriched pasta. Cereal Chemistry, 96, 967–976.

Bustos, M. C., Vignola, M. B., Paesani, C., & León, A. E. (2020). Berry fruits-enriched pasta: Effect of processing and in vitro digestion on phenolics and its antioxidant activity, bioaccessibility and potential bioavailability. International Journal of Food Science & Technology, 55, 2104–2112.

Cao, H., Ou, J., Chen, L., Zhang, Y., Szkudelski, T., Delmas, D., Daglia, M., & Xiao, J. (2019). Dietary polyphenols and type 2 diabetes: Human study and clinical trial. Critical Reviews in Food Science and Nutrition, 59, 3371–3379.

Cisneros-Yupanqui, M., Zagotto, A., Alberton, A., Lante, A., Zagotto, G., Ribaudo, G., & Rizzi, C. (2020). Study of the phenolic profile of a grape pomace powder and its impact on delaying corn oil oxidation. Natural Product Research, 0, 1–5.

Cleary, L., & Brennan, C. (2006). The influence of a (1 → 3)(1 → 4)-β-D-glucan rich fraction from barley on the physico-chemical properties and in vitro reducing sugars release of durum wheat pasta. International Journal of Food Science & Technology, 41, 910–918.

Crizel, T. D. M., Rios, A. D. O., Thys, R. C. S., & Flôres, S. H. (2015). Effects of orange by-product fiber incorporation on the functional and technological properties of pasta. Food Science Technology, 35, 546–551.

Englyst, H. N., Kingman, S. M., & Cummings, J. H. (1992). Classification and measurement of nutritionally important starch fractions. European Journal of Clinical Nutrition. https://doi.org/10.1016/S0271-5317(97)00010-9

European Parliament. (2006). The regulation (EC) N. 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Official Journal of the European Union, 9–25.

Fuentes-Zaragoza, E., Sánchez-Zapata, E., Sendra, E., Sayas, E., Navarro, C., Fernández-Lõpez, J., & Pérez-Alvarez, J. A. (2011). Resistant starch as prebiotic: A review. Starch/staerke, 63, 406–415.

Gaita, C., Alexa, E., Moigradean, D., Conforti, F., & Poiana, M.-A. (2020). Designing of high value-added pasta formulas by incorporation of grape pomace skins. Rom Biotechnology lettuce, 25, 1607–1614.

Garcia-Valle, D. E., Bello-Pérez, L. A., Agama-Acevedo, E., & Alvarez-Ramirez, J. (2021). Structural characteristics and in vitro starch digestibility of pasta made with durum wheat semolina and chickpea flour. LWT, 145, 111347. https://doi.org/10.1016/j.lwt.2021.111347

Giuberti, G., Gallo, A., Cerioli, C., Fortunati, P., & Masoero, F. (2015). Cooking quality and starch digestibility of gluten free pasta using new bean flour. Food Chemistry, 175, 43–49.

Giuberti, G., Rocchetti, G., & Lucini, L. (2020). Interactions between phenolic compounds, amylolytic enzymes and starch: An updated overview. Current Opinion in Food Science, 31, 102–113.

Granfeldt, Y., Björck, I., Drews, A., & Tovar, J. (1992). An in vitro method based on chewing to predict metabolic responses to starch in cereal and legumes products. European Journal of Clinical Nutrition, 46, 649–660.

Jeon, H. J., & Lee, J. H. (2021). Quality and antioxidant properties of wheat cookies supplemented with maqui berry powder. Korean J Food Preserv, 28, 480–488.

Kim, B. R., Kim, S., Bae, G. S., Chang, M. B., & Moon, B. K. (2017). Quality characteristics of common wheat fresh noodle with insoluble dietary fiber from kimchi by-product. LWT, 85, 240–245.

Lehmann, U., & Robin, F. (2007). Slowly digestible starch - Its structure and health implications: A review. Trends in Food Science & Technology, 18, 346–355.

Littardi, P., Paciulli, M., Carini, E., Rinaldi, M., Rodolfi, M., & Chiavaro, E. (2020). Quality evaluation of chestnut flour addition on fresh pasta. LWT, 126, 109303.

Lončarić, A., Kosović, I., Jukić, M., Ugarčić, Ž, & Piližota, V. (2014). Effect of apple by-product as a supplement on antioxidant activity and quality parameters of pasta. Croat Journal of the Food Science and Technology, 6, 97–103.

Misle, E., Garrido, E., Contardo, H., & González, W. (2011). Maqui [Aristotelia chilensis (Mol.) Stuntz]-the amazing chilean tree: A review. Journal of Agriculture Science and Technology B, 1, 473–482.

Molnar, D., Vujić, L., Gyimes, E., Krisch, J., & RimacBrnčić, S. (2015). Characterization of biscuits enriched with black currant and jostaberry powder. Croatia Journal of Food Technology and Biotechnology Nutrition, 10, 31–36.

Murray, J. C., Kiszonas, A. M., & Morris, C. F. (2018). Influence of soft kernel texture on fresh durum pasta. Journal of Food Science, 83, 2812–2818.

Nocente, F., Taddei, F., Galassi, E., & Gazza, L. (2019). Upcycling of brewers’ spent grain by production of dry pasta with higher nutritional potential. LWT, 114, 108421.

Rainero, G., Bianchi, F., Rizzi, C., Cervini, M., Giuberti, G., & Simonato, B. (2021). Breadsticks fortification with red grape pomace: Effect on nutritional, technological, and sensory properties. Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.11596

Rakhesh, N., Fellows, C. M., & Sissons, M. (2015). Evaluation of the technological and sensory properties of durum wheat spaghetti enriched with different dietary fibres. Journal of the Science of Food and Agriculture, 95, 2–11.

Rocchetti, G., Rizzi, C., Pasini, G., Lucini, L., Giuberti, G., & Simonato, B. (2020). Effect of Moringa oleifera L. leaf powder addition on the phenolic bioaccessibility and on in vitro starch digestibility of durum wheat fresh pasta. Foods. https://doi.org/10.3390/foods9050628

Rocchetti, G., Bhumireddy, S. R., Giuberti, G., Mandal, R., Lucini, L., & Wishart, D. S. (2019). Edible nuts deliver polyphenols and their transformation products to the large intestine: An in vitro fermentation model combining targeted/untargeted metabolomics. Food Research International, 116, 786–794.

Rocchetti, G., Rizzi, C., Cervini, M., Rainero, G., Bianchi, F., Giuberti, G., Lucini, L., & Simonato, B. (2021). Impact of grape pomace powder on the phenolic bioaccessibility and on in vitro starch digestibility of wheat based bread. Foods, 10(3), 507. https://doi.org/10.3390/foods10030507

Rodríguez Montealegre, R., Romero Peces, R., ChacónVozmediano, J. L., MartínezGascueña, J., & García Romero, E. (2006). Phenolic compounds in skins and seeds of ten grape Vitis vinifera varieties grown in a warm climate. Journal of Food Composition and Analysis, 19, 687–693.

Rothwell, J. A., Knaze, V., & Zamora-Ros, R. (2017). Polyphenols: Dietary assessment and role in the prevention of cancers. Current Opinion in Clinical Nutrition and Metabolic Care, 20, 512–521.

Sant’Anna V, Christiano FDP, Marczak LDF, Tessaro IC, Thys RCS,. (2014). The effect of the incorporation of grape marc powder in fettuccini pasta properties. LWT, 58, 497–501.

Simonato, B., Tolve, R., Rainero, G., Rizzi, C., Sega, D., Rocchetti, G., & Giuberti, G. (2020). Technological, nutritional, and sensory properties of durum wheat fresh pasta fortified with Moringa oleifera L. leaf powder. Journal of the Science of Food and Agriculture. https://doi.org/10.1002/jsfa.10807

Simonato, B., Trevisan, S., Tolve, R., Favati, F., & Pasini, G. (2019). Pasta fortification with olive pomace: Effects on the technological characteristics and nutritional properties. LWT. https://doi.org/10.1016/j.lwt.2019.108368

Singh, J., Dartois, A., & Kaur, L. (2010). Starch digestibility in food matrix: A review. Trends in Food Science & Technology, 21, 168–180.

Sissons, M. (2022). Development of novel pasta products with evidence based impacts on health — A review. Foods, 11(1), 123. https://doi.org/10.3390/foods11010123

Sun, L., & Miao, M. (2020). Dietary polyphenols modulate starch digestion and glycaemic level: A review. Critical Reviews in Food Science and Nutrition, 60, 541–555.

Tian, S., & Sun, Y. (2020). Influencing factor of resistant starch formation and application in cereal products: A review. International Journal of Biological Macromolecules, 149, 424–431.

Tolve, R., Pasini, G., Vignale, F., Favati, F., & Simonato, B. (2020). Effect of grape pomace addition on the technological, sensory, and nutritional properties of durum wheat pasta. Foods, 9, 1–11.

Tolve, R., Simonato, B., Rainero, G., Bianchi, F., Rizzi, C., Cervini, M., & Giuberti, G. (2021). Wheat bread fortification by grape pomace powder: Nutritional, technological, antioxidant, and sensory properties. Foods, 10, 1–12.

Wang, J., Brennan, M. A., Serventi, L., & Brennan, C. S. (2021). Impact of functional vegetable ingredients on the technical and nutritional quality of pasta. Critical Reviews in Food Science and Nutrition, 0, 1–12.

Zúñiga, G. E., Tapia, A., Arenas, A., Contreras, R. A., & Zúñiga-Libano, G. (2017). Phytochemistry and biological properties of Aristotelia chilensis a Chilean blackberry: A review. Phytochemistry Reviews, 16, 1081–1094.

Funding

Open access funding provided by Università degli Studi di Verona within the CRUI-CARE Agreement.

Author information

Authors and Affiliations

Contributions

Conceptualization: B.S. and F.B.; formal analysis: F.B. and M.C.; methodology: B.S. and G.G.; data curation: F.B., B.S., G.G., and M.C.; original draft preparation: F.B., G.G., B.S., and M.C.; review and editing: B.S., F.B., and G.G.

Corresponding author

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics Approval

The study was conducted according to the guidelines of the Declaration of Helsinki and approved by the Ethics Committee of Policlinico Gemelli Hospital (authorization number 5289/15).

Consent to Participate

Informed consent was obtained from all subjects involved in the sensory study.

Consent for Publication

All authors have read and agreed to the published version of the manuscript.

Conflict of Interest

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Bianchi, F., Giuberti, G., Cervini, M. et al. Fortification of Durum Wheat Fresh Pasta with Maqui (Aristotelia chilensis) and Its Effects on Technological, Nutritional, Sensory Properties, and Predicted Glycemic Index. Food Bioprocess Technol 15, 1563–1572 (2022). https://doi.org/10.1007/s11947-022-02838-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-022-02838-9