Abstract

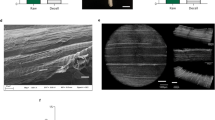

In vitro meat is an edible muscle tissue produced in a laboratory using bioengineering tools, avoiding the slaughter of farmed animals. In the early stages of in vitro meat production, the muscle cells need to be oriented and aligned to form muscle fibers. Additionally, the adherent muscle cells require an appropriate matrix where they can proliferate and differentiate. In this work, a film (matrix) was formulated with edible biopolymers and then shaped using micropattern mold and cold-casting technique. The mold was fabricated by using a laser cutter, allowing building parallel microchannels of ~ 70 μm wide. The film surface was suitable for laying muscle cells in a fiber-like array. Microstructural characterization of the micropatterned structures was done by using stereoscopic microscope and scanning electron microscopy. The micropatterned films displayed high biocompatibility, allowing muscle cell adhesion (~ 70%) and growth (doubling time ~ 18 h). Fluorescence microscopy was used to study the morphology of the cells cultured onto the micropatterned films, showing fiber-like morphology (~ 80-μm fiber diameters). The shape and size of the obtained cells mimic the muscle fiber. By using immunofluorescence microscopy, the expression of specific myogenic markers was identified. These results confirm that edible films made by casting on micropatterned molds can be used for in vitro meat production.

Similar content being viewed by others

References

Acevedo, C. A., López, D. A., Tapia, M. J., Enrione, J., Skurtys, O., Pedreschi, F., Brown, D. I., Creixell, W., & Osorio, F. (2012). Using RGB image processing for designing an alginate edible film. Food and Bioprocess Technology, 5(5), 1511–1520.

Andrés, V., & Walsh, K. (1996). Myogenin expression, cell cycle withdrawal, and phenotypic differentiation are temporally separable events that precede cell fusion upon myogenesis. Journal of Cell Biology, 132(4), 657–666.

Bian, W., & Bursac, N. (2009). Engineered skeletal muscle tissue networks with controllable architecture. Biomaterials, 30(7), 1401–1412.

Burattini, S., Ferri, P., Battistelli, M., Curci, R., Luchetti, F., & Falcieri, E. (2004). C2C12 murine myoblasts as a model of skeletal muscle development: Morpho-functional characterization. European Journal of Histochemistry, 48(3), 223–233.

Capetanaki, Y., Milner, D. J., & Weitzer, G. (1997). Desmin in muscle formation and maintenance: Knockouts and consequences. Cell Structure and Function, 22(1), 103–116.

Chen, Y., Stegaev, V., Kouri, V. P., Sillat, T., Chazot, P. L., Stark, H., Wen, J. G., & Konttinen, Y. T. (2015). Identification of histamine receptor subtypes in skeletal myogenesis. Molecular Medicine Reports, 11(4), 2624–2630.

Datar, I., & Betti, M. (2010). Possibilities for an in vitro meat production system. Innovative Food Science and Emerging Technologies, 11(1), 13–22.

Díaz, P., López, D., Matiacevich, S., Osorio, F., & Enrione, J. (2011). State diagram of salmon (Salmo salar) gelatin films. Journal of the Science of Food and Agriculture, 91(14), 2558–2565.

Enrione, J. I., Sáez, C., López, D., Skurtys, O., Acevedo, C., Osorio, F., MacNaughtan, W., & Hill, S. (2012). Structural relaxation of salmon gelatin films in the glassy state. Food and Bioprocess Technology, 5(6), 2446–2453.

Enrione, J., Blaker, J. J., Brown, D. I., Weinstein-Oppenheimer, C. R., Pepczynska, M., Olguín, Y., Sánchez, E., & Acevedo, C. A. (2017). Edible scaffolds based on non-mammalian biopolymers for myoblast growth. Materials, 10(12), 1404.

Enrione, J., Pino, K., Pepczynska, M., Brown, D. I., Ortiz, R., Sánchez, E., & Acevedo, C. A. (2018). A novel biomaterial based on salmon-gelatin and its in-vivo evaluation as sterile wound-dressing. Materials Letters, 212(1), 159–164.

Goodwin, J. N., & Shoulders, C. W. (2013). The future of meat: A qualitative analysis of cultured meat media coverage. Meat Science, 95(3), 445–450.

Kroehne, V., Heschel, I., Schügner, F., Lasrich, D., Bartsch, J. W., & Jockusch, H. (2008). Use of a novel collagen matrix with oriented pore structure for muscle cell differentiation in cell culture and in grafts. Journal of Cellular and Molecular Medicine, 12(5A), 1640–1648.

Kurth, F., Franco-Obregón, A., Bärtschi, C. A., & Dittrich, P. S. (2015). An adaptable stage perfusion incubator for the controlled cultivation of C2C12 myoblasts. Analyst, 140(1), 127–133.

Langelaan, M. L. P., Boonen, K. J. M., Polak, R. B., Baaijens, F. P. T., Post, M. J., & van der Schaft, D. W. J. (2010). Meet the new meat: Tissue engineered skeletal muscle. Trends in Food Science & Technology, 21(2), 59–66.

Lawrie, R. A., & Ledward, D. A. (2006). Lawrie's meat science (7th ed.). Cambridge: Woodhead Publishing Limited.

Li, G., Zhao, X., Zhao, W., Zhang, L., Wang, C., Jiang, M., Gu, X., & Yang, Y. (2014). Porous chitosan scaffolds with surface micropatterning and inner porosity and their effects on Schwann cells. Biomaterials, 35(30), 8503–8513.

Papenburg, B. J., Vogelaar, L., Bolhuis-Versteeg, L. A., Lammertink, R. G., Stamatialis, D., & Wessling, M. (2007). Biomaterials, 28(11), 1998–2009.

Post, M. J. (2012). Cultured meat from stem cells: Challenges and prospects. Meat Science, 92(3), 297–301.

Post, M. J. (2014). An alternative animal protein source: Cultured beef. Annals of the New York Academy of Sciences, 1328(1), 29–33.

Schuster, E., Wallin, P., Klose, F. P., Gold, J., & Strom, A. (2017). Correlating network structure with functional properties of capillary alginate gels for muscle fiber formation. Food Hydrocolloids, 72(1), 210–218.

Théry, M. (2010). Micropatterning as a tool to decipher cell morphogenesis and functions. Journal of Cell Science, 123(24), 4201–4213.

Verbeke, W., Marcu, A., Rutsaert, P., Gaspar, R., Seibt, B., Fletcher, D., & Barnett, J. (2015). Would you eat cultured meat? Consumers' reactions and attitude formation in Belgium, Portugal and the United Kingdom. Meat Science, 102(1), 49–58.

Yan, W., George, S., Fotadar, U., Tyhovych, N., Kamer, A., Yost, M. J., Price, R. L., Haggart, C. R., Holmes, J. W., & Terracio, L. (2007). Tissue engineering of skeletal muscle. Tissue Engineering, 13(11), 2781–2790.

Acknowledgments

The authors would like to thank financial support from FONDECYT Grant 1160311 (CONICYT, Chile).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Acevedo, C.A., Orellana, N., Avarias, K. et al. Micropatterning Technology to Design an Edible Film for In Vitro Meat Production. Food Bioprocess Technol 11, 1267–1273 (2018). https://doi.org/10.1007/s11947-018-2095-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-018-2095-4