Abstract

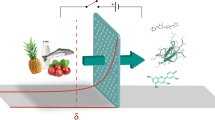

Beer is one of the most consumed beverages in the world, placing the brewing sector in a strategic economic position in the food industry. Beer production has a series of physical and chemical steps that are technically intensive when the production scale is increased. Although the production techniques have been improving for hundreds of years, many breweries still employ traditional techniques. The increasing consumption of beer and the competitive market have led the industry to search for alternative technologies to produce a better beer with reduced prices. Membrane separation processes are interesting alternatives that may be utilised in several steps of beer production and may replace some traditional and time-consuming techniques. The objective of this study is to summarise and present a literature survey of the membrane separation processes that are currently applied in the beer industry and those processes that have potential for future applications. The potential of microfiltration, ultrafiltration, reverse osmosis, pervaporation, and gas separation to accomplish almost all solid–liquid–gas separations in a brewery is discussed, providing a clear outline for researchers on the main aspects and developments of the beer-membrane field.

Similar content being viewed by others

References

Alfa-Laval. (2003). Innovation in beer filtration gathers momentum. Lund, Sweden. Retrieved from http://www.alfalaval.com/about-us/press/product-press/Documents/071106_cross_flow_en.pdf

Alfa-Laval. (2007). Top end beer from cross-flow filters. Filtration & Separation, 44(2), 40–41. Retrieved from http://www.sciencedirect.com/science/article/pii/S0015188207700575.

Alfa-Laval. (2013). Alfa Laval beer recovery system. Alfa-Laval. Retrieved from http://www.alfalaval.com/solution-finder/products/membrane-filtration-systems/Documents/PCM00069EN_LOWRES_beer recovery.pdf

Almonacid, S. F., Nájera, A. L., Young, M. E., Simpson, R. J., & Acevedo, C. A. (2010). A comparative study of stout beer batch fermentation using free and microencapsulated yeasts. Food and Bioprocess Technology, 5(2), 750–758.

Asano, S., Suzuki, K., Iijima, K., Motoyama, Y., Kuriyama, H., & Kitagawa, Y. (2007). Effects of morphological changes in beer-spoilage lactic acid bacteria on membrane filtration in breweries. Journal of Bioscience and Bioengineering, 104(4), 334–338.

Baker, R. W. (2004). Membrane technology and applications (2nd ed., p. 545). Chichester, England: Wiley.

Bamforth, C. W. (2003). Beer—tap into the art and science of brewing (2nd edition, p. 246). New York: Oxford University Press Inc.

Bamforth, C. W. (2006). Brewing: new technologies. (C. W. Bamforth, Ed.) (p. 501). Boca Raton: CRC Press Inc.

Bamforth, C. W. (2008). Beer: a quality perspective (Handbook of Alcoholic Beverages). (I. Russel, C. W. Bamforth, & G. G. Stewart, Eds.) (1st Edition, p. 287). California: Academic Press.

Barchet, R. (1993). Hot trub, formation and removal. Brewing Techniques, 1(4). Retrieved from http://morebeer.com/brewingtechniques/library/backissues/issue1.4/barchet.html

Barchet, R. (1994). Cold trub: implications for finished beer and methods of removal. Brewing Techniques, 2(2).

Barth, N. (1989). Process for the production of fermented drinks with reduced alcohol content. US patent No 4804554.

Benítez, E. I., Amezaga, N. M. J. M., Sosa, G. L., Peruchena, N. M., & Lozano, J. E. (2013). Turbidimetric behavior of colloidal particles in beer before filtration process. Food and Bioprocess Technology, 6(4), 1082–1090.

Blanpain, P., & Lalande, M. (1997). Investigation of fouling mechanisms governing permeate flux in the crossflow microfiltration of beer. Filtration and Separation, 34(10), 1065–1069.

Blanpain-Avet, P., Doubrovine, N., Lafforgue, C., & Lalande, M. (1999a). The effect of oscillatory flow on crossflow microfiltration of beer in a tubular mineral membrane system—membrane fouling resistance decrease and energetic considerations. Journal of Membrane Science, 152(2), 151–174.

Blanpain-Avet, P., Fillaudeau, L., & Lalande, M. (1999b). Investigation of mechanisms governing membrane fouling and protein rejection in the sterile microfiltration of beer with an organic membrane. Food and Bioproducts Processing, 77(2), 75–89.

BMG. (2011). World beer production increased again in 2010. (B. Manager, Ed.). Beverage Manager. Retrieved August 28, 2013, from http://beveragemanager.net

Bock, M., & Oechsle, D. (1999). Beer recovery from spent yeast with Keraflux membranes. The Brewer, 85(7), 340–345.

Brányik, T., Silva, D. P., Baszczynski, M., Lehnert, R., & Almeida e Silva, J. B. (2012). A review of methods of low alcohol and alcohol-free beer production. Journal of Food Engineering, 108(4), 493–506.

BRAUWELT. (2000). Non-dispersive diffusion for nitrogenation. Brauwelt International.

Briggs, D. E., Boulton, C. A., Brookes, P. A., & Stevens, R. (2004). Brewing: science and practice (1st edition, p. 864). Boca Raton: CRC Press Inc.

Brunetti, A., Scura, F., Barbieri, G., & Drioli, E. (2010). Membrane technologies for CO2 separation. Journal of Membrane Science, 359(1–2), 115–125.

Brüschke, H. E. A. (1990). Removal of ethanol from aqueous streams by pervaporation. Desalination, 77, 323–330.

Bühler, T., Burell, K., Eggars, H. U., Reed, R. J. R., & Olajire, A. A. (1993). The application of membranes for new approach to brewery operations. In European Brewing Convention Congress (pp. 691–700). Olso: Oxford.

Burrell, K. J., Reed, R. J. R., Burrell, B. K. J., Hall, L., & Road, H. (1994). Crossflow microfiltration of beer: laboratory-scale studies on the effect of pore size. Filtration and Separation, 31(4), 399–406.

Catarino, M., & Mendes, A. (2011). Non-alcoholic beer—a new industrial process. Separation and Purification Technology, 79(3), 342–351.

Catarino, M., Mendes, A., Madeira, L., & Ferreira, A. (2006). Beer dealcoholization by reverse osmosis. Desalination, 200, 397–399.

Catarino, M., Mendes, A., Madeira, L. M., & Ferreira, A. (2007). Alcohol removal from beer by reverse osmosis. Separation Science and Technology, 42(13), 3011–3027.

Catarino, M., Ferreira, A., & Mendes, A. (2009). Study and optimization of aroma recovery from beer by pervaporation. Journal of Membrane Science, 341(1–2), 51–59.

Czekaj, P., López, F., & Güell, C. (2000). Membrane fouling during microfiltration of fermented beverages. Journal of Membrane Science, 166(2), 199–212.

Daoud, I. (1985). Crossflow filtration: an alternative for mash separation. Brewing and Distilling International, 23(5), 31–32.

Daoud, I. (1989). Separation of wort from mash. US patent No 4844932.

Daoud, I. (1992). Crossflow filtration: an alternative mash separation. The Brewhouse BDI, 5, 18–19.

Daufin, G., Escudier, J. P., Carrère, H., Bérot, S., Fillaudeau, L., Decloux, M., … Carre, H. (2001). Recent and emerging applications of membrane processes in the food and dairy industry. Institution of Chemical Engineers, 79(June), 89–102.

De Castro, M. D. L., Capote, F. P., & Ávila, N. S. (2008). Is dialysis alive as a membrane-based separation technique? TrAC - Trends in Analytical Chemistry, 27(4), 315–326.

Delvaux, F., Deams, V., Vanmachelen, H., Neven, H., & Derdelinckx, G. (1995). Retention of beer flavours by the choice of appropriate glass. Proceedings of the EBC Congress, 25, 533–542.

Diban, N., Urtiaga, A., & Ortiz, I. (2008). Recovery of key components of bilberry aroma using a commercial pervaporation membrane. Desalination, 224(1–3), 34–39.

Drioli, E., & Fontananova, E. (2004). Membrane technology and sustainable growth. Chemical Engineering Research and Design, 82(12), 1557–1562.

Echt, W., & Meister, P. (2009). Design, fabrication and startup of an offshore membrane CO2 removal system . (G. P. Association, Ed.)88th Annual Convention - UOP LLC. Gas Processors Association.

Esslinger, H. M. (1990). Technological evaluation of various methods for recovering beer from spent yeast. In E. B. Convention (Ed.), Proceedings of European Brewing Convention (pp. 140–150). Leuven - Belgium: The Brewers of Europe.

Eumann, M., & Schildbach, S. (2012). 125th Anniversary Review: water sources and treatment in brewing. Journal of the Institute of Brewing, 118(1), 12–21. doi:10.1002/jib.18.

Favre, E. (2007). Carbon dioxide recovery from post-combustion processes: can gas permeation membranes compete with absorption? Journal of Membrane Science, 294, 50–59.

Ferreira, I. M. P. L. V. O., Pinho, O., Vieira, E., & Tavarela, J. G. (2010). Brewer’s Saccharomyces yeast biomass: characteristics and potential applications. Trends in Food Science and Technology, 21(2), 77–84.

Fillaudeau, L., & Carrère, H. (2002). Yeast cells, beer composition and mean pore diameter impacts on fouling and retention during cross-flow filtration of beer with ceramic membranes. Journal of Membrane Science, 196(1), 39–57.

Fillaudeau, L., Blanpain-Avet, P., & Daufin, G. (2006). Water, wastewater and waste management in brewing industries. Journal of Cleaner Production, 14(5), 463–471.

Fillaudeau, L., Boissier, B., Moreau, A., Blanpain-avet, P., Ermolaev, S., Jitariouk, N., et al. (2007). Investigation of rotating and vibrating filtration for clarification of rough beer. Journal of Food Engineering, 80(1), 206–217.

Galitsky, C., Martin, N., Worrell, E., Lehman, B., & Worrel, E. (2003). Energy efficiency improvement and cost saving opportunities for breweries (p. 74). Berkeley: University of California.

Gan, Q. (2001). Beer clarification by cross-flow microfiltration—effect of surface hydrodynamics and reversed membrane morphology. Chemical Engineering and Processing Process Intensification, 40(5), 413–419.

Gan, Q., Field, R. W., McKechnie, M. T., Shaughnessy, C. L. O., Bird, M. R., England, R., … O’Shaughnessy, C. L. (1997). Beer clarification by cross-flow microfiltration: fouling mechanisms and flux enhancement. Institution of Chemical Engineers, 75(1), 6.

Gan, Q., Howell, J. A., Field, R. W., England, R., Bird, M. R., & McKechinie, M. T. (1999). Synergetic cleaning procedure for a ceramic membrane fouled by beer microfiltration. Journal of Membrane Science, 155(2), 277–289.

Gan, Q., Howell, J. . A., Field, R. . W., England, R., Bird, M. . R., O’Shaughnessy, C. L., … O’Shaughnessy, C. . (2001). Beer clarification by microfiltration—product quality control and fractionation of particles and macromolecules. Journal of Membrane Science, 194(2), 185–196.

GEA. (2009). 100 Years Beer Separation with GEA Westfalia Separator. GEA Westfalia Separator Division. GEA Westfalia Separator Gmbh. Retrieved from http://www.westfalia-separator.com/fileadmin/Media/PDFs/Digest/SeparatorsDigest-2009-3-EN-100-Years-beer-separation.pdf.

GEA. (2012). CO2 recovery: Simple application—double profit. Kitzingen—Germany: GEA Process Engineering. Retrieved from http://www.geabrewery.com/geabrewery/cmsresources.nsf/filenames/Refrigeration_E_0712.pdf/$file/Refrigeration_E_0712.pdf.

GEA. (2013). Systems and processes in breweries. GEA Westfalia Separator Division. Oelde. Retrieved from http://www.westfalia-separator.com/fileadmin/Media/PDFs/Brochures/Breweries-BE-12-10-0004.pdf.

Granite, E. J., & O’Brien, T. (2005). Review of novel methods for carbon dioxide separation from flue and fuel gases. Fuel Processing Technology, 86(14–15), 1423–1434.

Gupta, M., Abu-Ghannam, N., & Gallaghar, E. (2010). Barley for brewing: characteristic changes during malting, brewing and applications of its by-products. Comprehensive Reviews in Food Science and Food Safety, 9(3), 318–328.

Ho, S. V, & Sheridan, P. W. (2002). Membrane process for making enhanced flavor fluids. US patent No 6419829.

Hurt, E., Zulewska, J., Newbold, M., & Barbano, D. M. (2010, December 1). Micellar casein concentrate production with a 3X, 3-stage, uniform transmembrane pressure ceramic membrane process at 50°C1. Journal of Dairy Science. American Dairy Science Association.

Karlsson, H. O. E., & Tragardh, G. (1996). Applications of pervaporation in food processing. Trends in Food Science and Technology, 7(3), 78–83.

Kavanagh, T. E., Clarke, B. J., Gee, P. S., Miles, M., & Nicholson, B. N. (1991). Volatile flavor compounds in low alcohol beers. Technical Quarterly—Master Brewers Association of the Americas, 28(3), 111–118.

Khan, F. I., & Ghoshal, A. K. (2000). Removal of volatile organic compounds from polluted air. Journal of Loss Prevention in the Process Industries, 13(6), 527–545.

Kosseva, M. R. (2010). Immobilization of microbial cells in food fermentation processes. Food and Bioprocess Technology, 4(6), 1089–1118.

Kuiper, S., van Rijn, C., Nijdam, W., Raspe, O., van Wolferen, H., Krijnen, G., et al. (2002). Filtration of lager beer with microsieves: flux, permeate haze and in-line microscope observations. Journal of Membrane Science, 196(2), 159–170.

Light, W. G. (1986). Continuous recycling process for the production of low alcoholic beverages. US patent No 4617127.

Light, W. G., Mooney, L. A., Chu, H. C., & Wood, S. K. (1986). Alcohol removal from beer by reverse osmosis. AIChE Symposium Series, 82, 1–8.

Magalhães, P. J., Dostalek, P., Cruz, J. M., Guido, L. F., & Barros, A. A. (2008). The impact of a xanthohumol-enriched hop product on the behavior of xanthohumol and isoxanthohumol in pale and dark beers: a pilot scale approach. Journal Institute of Brewing, 114(3), 246–256.

Matsumoto, K., Katsuyama, S. S., & Ohya, H. (1987). Separation of yeast by cross-flow filtration with backwashing. Journal of Fermentation Technology, 65(1), 77–83.

Mellcom. (2012). Carbon dioxide recovery plant. New Delhi—India: Mellcon Engineers Pvt Ltd. Retrieved from http://www.mellcon.com/co2-recovery-plant.asp

Montanari, L., Marconi, O., Mayer, H., & Fantozzi, P. (2009). Production of alcohol-free beer. In V. R. Preedy (Ed.), Beer in health and disease prevention (pp. 61–75). Burlington: Elsevier Inc.

Moonen, H., & Niefind, H. J. (1982). Alcohol reduction in beer by means of dialysis. Desalination, 41(3), 327–335.

Murkes, J. (1986). Low shear and high shear crossflow filtration. Filtration and Separation, 23(6), 364–366.

Mussatto, S. I., Dragone, G., & Roberto, I. C. (2006). Brewers’ spent grain: generation, characteristics and potential applications. Journal of Cereal Science, 43(1), 1–14.

O’Reilly, S. M. G., Lummis, D. J., & Molzahn, S. W. (1987). The application of ceramic filtration for the recovery of beer from tank bottoms and in beer filtration. In Proceedings of European Brewing Convention (pp. 639–646). Madrid - Spain.

Ohlrogge, K., Wind, J., & Brinkmann, T. (2010). Membranes for recovery of volatile organic compounds. In Comprehensive Membrane Science and Engineering (pp. 213–242). Oxford: Elsevier.

Pall. (2013). Keraflux - TFF System. Pall Corporation. Retrieved from http://www.pall.com/main/food-and-beverage/product.page?id=53876.

Pentair. (2012). Beverages systems. Pentair Water Process Technology BV. Retrieved from http://pentair.com/MarketLanding/resources/images/7662.pdf.

Pentair. (2013). Beer membrane filtration. Pentair Water Process Technology BV2. Retrieved from http://www.norit-bmf.com/facts & figures/.

Perry, E. J., & Coleman, A. R. (1987). Purification of carbon dioxide for use in brewing. US patent No 4699642.

Petkovska, M., Leskosek, I., & Nedovic, V. (1997a). Analysis of mass transfer in beer diafiltration with cellulose-based and polysulfone membranes. Institute of Chemical Engineers, 75(4), 247–252.

Petkovska, M., Leskosek, I., & Nedovic, V. (1997b). Analysis of mass transfer in beer diafiltration with cellulose-based and polysulfone membranes. Food and Bioproducts Processing, 75(4), 247–252.

Pilipovik, M. V., & Riverol, C. (2005). Assessing dealcoholization systems based on reverse osmosis. Journal of Food Engineering, 69(4), 437–441.

Priest, F. G., & Stewart, G. G. (Eds.). (2006). Handbook of brewing (2nd Edition, p. 830). Boca Raton: CRC Press Inc.

Rufford, T. E., Smart, S., Watson, G. C. Y., Graham, B. F., Boxall, J., Diniz da Costa, J. C., et al. (2012). The removal of CO2 and N2 from natural gas: a review of conventional and emerging process technologies. Journal of Petroleum Science and Engineering, 94–95, 123–154.

Sandblom, R. M. (1978). Filtering process. US patent No 4105547.

Schneider, J., & Weisser, H. (2004). Diafiltration of mash. Journal of the Institute of Brewing, 110(4), 326–334.

Schneider, J., Krottenthaler, M., Back, W., & Weisser, H. (2005). Study on the membrane filtration of mash with particular respect to the quality of wort and beer. Journal of the Institute of Brewing, 111, 380–387.

Sensidoni, M., Marconi, O., Perretti, G., Freeman, G., & Fantozzi, P. (2011). Monitoring of beer filtration using photon correlation spectroscopy (PCS). Journal of the Institute of Brewing, 117(4), 639–646.

Shotipruk, A., Kittianong, P., Suphantharika, M., & Muangnapoh, C. (2005). Application of rotary microfiltration in debittering process of spent brewer’s yeast. Bioresource Technology, 96(17), 1851–1859.

Sohrabvandi, S., Mousavi, S. M., Razavi, S. H., Mortazavian, A. M., & Rezaei, K. (2010). Alcohol-free beer: methods of production, sensorial defects, and healthful effects. Food Reviews International, 26(4), 335–352.

Starbard, N. (2008). Beverage industry microfiltration: a comprehensive guide (p. 303). Iowa: Wiley-Blackwell.

Stein, W. (1993). Dealcoholization of beer. Technical Quarterly—Master Brewers Association of the Americas, 30(2), 54–57.

Stewart, D. C., Hawthorne, D., & Evans, D. E. (1998). Cold sterile filtration: a small scale filtration test and investigation of membrane plugging. Journal of the Institute of Brewing, 104, 321–326.

Stopka, J., Schlosser, S., Dömény, Z., & Smogrovicova, D. (2000). Flux decline in microfiltration of beer and related solutions of model foulants through ceramic membranes. Polish Journal of Environmental Studies, 9(1), 65–69.

Tan, S., Li, L., Xiao, Z., Wu, Y., & Zhang, Z. (2005). Pervaporation of alcoholic beverages—the coupling effects between ethanol and aroma compounds. Journal of Membrane Science, 264(1–2), 129–136.

Tang, D.-S., Yin, G.-M., He, Y.-Z., Hu, S.-Q., Li, B., Li, L., … Borthakur, D. (2009). Recovery of protein from brewer’s spent grain by ultrafiltration. Biochemical Engineering Journal, 48(1), 1–5.

Tilgner, H. G., & Schmitz, F. J. (1987). Process for reducing alcohol in fermented beverages by means of dialysis. US patent No 4664918.

Tripp, M. L., Rader, S. R., Rao, S. C., & Ryder, D. S. (1997). Flavored malt beverages prepared by using ultrafiltration methods. US patent No 5618572.

Vadi, P., & Rizvi, S. S. (2001). Experimental evaluation of a uniform transmembrane pressure crossflow microfiltration unit for the concentration of micellar casein from skim milk. Journal of Membrane Science, 189(1), 69–82.

Van der Sman, R. G. M., Vollebregt, H. M., Mepschen, A., & Noordman, T. R. (2012). Review of hypotheses for fouling during beer clarification using membranes. Journal of Membrane Science, 396, 22–31.

Van Rijn, C. J. M., Nijdam, W., van der Stappen, L. A. V. G., Raspe, O. J. A., Broens, l., & van Hoof, S. C. J. M. (1997). Innovation in yeast cell filtration: cost saving technology with high flux membranes. In Proceedings of the EBC Congress (pp. 501–507).

Wenten, I. G., Taylour, J., Skou, F., Rasmussen, A., & Jonsson, G. (1994). Membrane cleaning after beer clarification. In Proceedings of European Brewing Convention (pp. 188–195). Sydney—Australia: University of New South Wales.

Wittemann. (2012). Carbon dioxide recovery (Brewery). Palm Coast—USA: Wittemann Company. Retrieved from http://www.pureco2nfidence.com/launch/images/downloads/literature/brewery/brewery_recovery_literature.pdf.

Yang, H., Xu, Z., Fan, M., Gupta, R., Slimane, R. B., Bland, A. E., et al. (2008). Progress in carbon dioxide separation and capture: a review. Journal of Environmental Sciences, 20(1), 14–27.

Yazdanshenas, M., Soltanieh, M., Tabatabaei, N., Reza, S. A., Fillaudeau, L., & Tabatabaei Nejad, S. A. R. (2010). Cross-flow microfiltration of rough non-alcoholic beer and diluted malt extract with tubular ceramic membranes: investigation of fouling mechanisms. Journal of Membrane Science, 362(1–2), 306–316.

Yeo, Z. Y., Chew, T. L., Zhu, P. W., Mohamed, A. R., & Chai, S.-P. (2012). Conventional processes and membrane technology for carbon dioxide removal from natural gas: a review. Journal of Natural Gas Chemistry, 21(3), 282–298.

Acknowledgements

The authors thank the National Council for Scientific and Technological Development (CNPq), the Coordination for the Improvement of Higher Level Personnel (CAPES), and the Research Support Foundation of the State of Rio Grande do Sul (FAPERGS) of Brazil.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Ambrosi, A., Cardozo, N.S.M. & Tessaro, I.C. Membrane Separation Processes for the Beer Industry: a Review and State of the Art. Food Bioprocess Technol 7, 921–936 (2014). https://doi.org/10.1007/s11947-014-1275-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-014-1275-0