Abstract

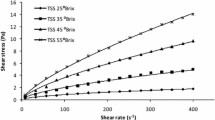

The rheological properties of tomato concentrates produced by hot and cold break have been extensively studied by many authors. Only a few studies, however, focus specifically with the rheology of reconstituted concentrates from tomato powders. In this study, the rheological properties of reconstituted tomato concentrate from lyophilized freeze-dried tomato juice were evaluated using rotational viscometer at temperatures 20 °C, 30 °C, 40 °C, 50 °C, and 60 °C and at concentrations of 9.7%, 12.9%, 20.5%, and 26.8% total soluble solids. Using power law model, both flow behavior index (n) and consistency coefficient (k) were determined. The calculated values of flow behavior index (n) were less than unity (0.03–0.28) at all temperatures and concentrations indicating the shear-thinning characteristic of the concentrate. The effect of temperature and concentration on the consistency coefficient (k) was studied. Positive correlation between k in the range of 1.57 and 38.33 Pa sn and inverse absolute temperature (1/T) has been shown by Arrhenius model. Additionally, linear correlation between consistency coefficient (k) and concentration (C) was determined. The activation energies were found in the range of 3.63 and 7.36 kJ/mol K depending on concentration. The results of this study might be useful to improve the design of processing operations dealing with tomato powder reconstitution.

Similar content being viewed by others

References

Abu-Jdayil, B., Banat, F., Jumah, R., Al-Asheh, S., & Hammad, S. (2004). A comparative study of rheological characteristics of tomato paste and tomato powder solutions. International Journal of Food Properties, 7(3), 483–497.

Altan, A., & Maskan, M. (2005). Rheological behavior of pomegranate (Punica granatum L.) juice and concentrate. Journal of Texture Studies, 36, 68–77.

Barett, D. M., Garcia, E., & Wayne, J. E. (1998). Textural modification of processing tomatoes. Critical Reviews in Food Science and Nutrition, 38(3), 173–258.

Barreiro, J. A. M., Sandoval, A. J. B., Guédez, A., & Luciani, Y. (1996). Comportamiento reológico de concentrados de tomate: efecto de la temperatura y la concentración. Archivos Latinoamericanos de Nutrición, 46(3), 224–229.

Bouzouita, N., Barbana, C., El Omri, A., Zgoulli, S., Hassouna, M., Chaabouni, M. M., et al. (2007). Use of locust bean gum in ketchup formulation: Rheological study. Acta Horticulturae, 758, 103–110.

Dak, M., Verma, R. C., & Sharma, G. P. (2006). Flow characteristics of juice of “Totapuri” mangoes. Journal of Food Engineering, 76, 557–561.

Dak, M., Verma, R. C., & Jaaffrey, S. N. A. (2008). Rheological properties of tomato concentrate. International Journal of Food Engineering, 4(7), Article 11.

Den Ouden, F. W. C., & Van Vliet, T. (2002). Effect of concentration on the rheology and serum separation of tomato suspensions. Journal of Texture Studies, 33, 91–104.

Farahnaky, A., Abbasi, A., Jamalian, J., & Mesbahi, G. (2008). The use of tomato pulp powder as a thickening agent in the formulation of tomato ketchup. Journal of Texture Studies, 39, 169–182.

Fito, P. J., Clemente, G., & Sanz, F. J. (1983). Rheological behaviour of tomato concentrate (hot break and cold break). Journal of Food Engineering, 2, 51–62.

Harper, J. C., & El Sahrigi, A. F. (1965). Viscometric behavior of tomato concentrates. Journal of Food Science, 30, 470–476.

Hayes, W. A., Smith, P. G., & Morris, A. E. J. (1998). The production and quality of tomato concentrates. Critical Reviews in Food Science and Nutrition, 38(7), 537–564.

Holsworth, S. D. (1971). Applicability of rheological models to the interpretation of flow and processing behaviour of fluid products. Journal of texture studies, 2, 393.

Ibarz, A. (1992). Rheology of clarified fruit juices. I: Peach juices. Journal of Food Engineering, 15, 49–61.

Jaya, S., & Das, H. (2009). Glass transition and sticky point temperatures and stability/mobility diagram of fruit powders. Food and Bioprocess Technology, 2, 89–95.

Lazarus, S. A., Bowen, K., & Garg, M. L. (2004). Tomato juice and platelet aggregation in type 2 diabetes. Journal of American Medical Association, 292(7), 805–806.

Marsh, G. L., Buhlert, J., & Leonard, S. (1977). Effect of degree of concentration and of heat treatment on consistency of tomato pastes after dilution. Journal of Food Processing and Preservation, 1(4), 340–346.

Sabanis, D., Tzia, C., & Papadakis, S. (2008). Effect of different raisin juice preparations on selected properties of gluten-free bread. Food and Bioprocess Technology, 1, 374–383.

Sathivel, S., Huang, J., & Prinyawiwatkul, W. (2008). Thermal properties and applications of the Arrhenius equation for evaluating viscosity and oxidation rates of unrefinded pollock oil. Journal of Food Engineering, 84, 187–193.

Schlüter, O., Foerster, J., Geyer, M., Knorr, D., & Herppich, W. B. (2009). Characterization of high-hydrostatic-pressure effects on fresh produce using chlorophyll fluorescence image analysis. Food and Bioprocess Technology, 2, 291–299.

Tanglertpaibul, T., & Rao, M. A. (1987a). Flow properties of tomato concentrates: Effect of serum viscosity and pulp content. Journal of Food Science, 52(2), 318–321.

Tanglertpaibul, T., & Rao, M. A. (1987b). Rheological properties of tomato concentrates as affected by particle size and methods of concentration. Journal of Food Science, 52(1), 141–145.

Tiziani, S., & Voldovotz, Y. (2005). Rheological characterization of a novel functional food: Tomato juice with soy germ. Journal of Agricultural and Food Chemistry, 53, 7267–7273.

Toor, R. K., & Savage, G. P. (2005). Antioxidant activity in different fractions of tomatoes. Food Research International, 38, 487–494.

Vercet, A., Sanchez, C., Burgos, J., Montanes, L., & Lopez Buesa, P. (2002). The effects of manothermosonication on tomato pectic enzymes and tomato paste rheological properties. Journal of Food Engineering, 53, 273–278.

Vitali, A. A., & Rao, M. A. (1984a). Flow properties of low-pulp concentrated orange juice: Effect of temperature and concentration. Journal of Food Science, 49, 882–888.

Vitali, A. A., & Rao, M. A. (1984b). Flow properties of low-pulp concentrated orange juice: serum viscosity and effect of pulp content. Journal of Food Science, 49, 876–881.

Xu, S. Y., Shoemaker, C. F., & Luh, B. S. (1986). Effect of break temperature on rheological properties and microstructure of tomato juices and pastes. Journal of Food Science, 51(2), 399–402.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Barbana, C., El-Omri, A. Viscometric Behavior of Reconstituted Tomato Concentrate. Food Bioprocess Technol 5, 209–215 (2012). https://doi.org/10.1007/s11947-009-0270-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-009-0270-3