Abstract

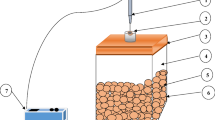

Respiration of the produce and permeation of gas through the packaging films are the processes involved in creating a modified atmosphere inside a package that will extend shelf life of agricultural perishables. Thus modeling respiration rate of the selected produce is crucial to the design of a successful modified atmosphere packaging system. Two different models based on regression analysis and enzyme kinetics were developed with the help of respiration data generated at temperatures 0, 5, 10, 15, 20, 25, and 30 °C for litchi fruit using the closed system method. Temperature was found to influence the model parameters. In the model, based on enzyme kinetics, the dependence of respiration rate on O2 and CO2 was found to follow the uncompetitive inhibition. The enzyme kinetic model parameters, calculated from the respiration rate at different O2 and CO2 concentration were used to fit the Arrhenius equation against different storage temperature. The regression coefficients values were used for the prediction of respiration rate using regression model. The activation energy and respiration pre-exponential factor were used to predict the model parameters of enzyme kinetics at any storage temperature. The developed models were tested for its validity at 2 °C. The models showed good agreement with the experimentally estimated respiration rate.

Similar content being viewed by others

Abbreviations

- a :

-

Regression coefficient

- b :

-

Regression coefficient, h

- E :

-

Mean relative deviation modulus, %

- E a :

-

Activation energy, kJ g−1mol−1

- k m(O2) :

-

Michaelis–Menten constant for O2 consumption, % O2

- k m(CO2) :

-

Michaelis–Menten constant for CO2 evolution, % O2

- k i(O2) :

-

Inhibition constants for O2 consumption, % CO2

- k i(CO2) :

-

Inhibition constants for CO2 evolution, % CO2

- N :

-

Number of respiration data points

- R :

-

Universal gas constant, 8.314 kJ kg−1 mol −1K−1

- R CO2 :

-

Respiration rate, ml [CO2] kg−1 h−1

- R exp :

-

Experimental respiration rate, ml kg−1 h−1

- R m :

-

Model parameter of enzyme kinetic

- R pre :

-

Predicted respiration rate, ml kg−1 h−1

- R O2 :

-

Respiration rate, ml [O2] kg−1 h−1

- R p :

-

Respiration pre-exponential factor

- T :

-

Storage temperature °C

- T abs :

-

Storage temperature, K

- t :

-

Storage time, h

- Δt :

-

Time difference between two gas measurements

- V f :

-

Free volume of the respiration chamber, ml

- v m(CO2) :

-

Maximum respiration rate for CO2 evolution, ml/kg-h

- v m(O2) :

-

Maximum respiration rate for O2 consumption, ml/kg-h

- W :

-

Weight of litchi fruit, kg

- Y O2 :

-

Oxygen concentration, decimal

- Z CO2 :

-

Carbon dioxide concentration, decimal

References

Anon (2006). Agricultural statistics at a glace. New Delhi, India: IFFCO, Arihant Offset.

Bhande, S. D., Ravindran, M. R., & Goswami, T. K. (2008). Respiration rates of banana fruits under aerobic conditions at different storage temperatures. Journal of Food Engineering, 87(1), 116–23. doi:10.1016/j.jfoodeng.2007.11.019.

Cameron, A. C., Boylan-Pett, W., & Lee, J. (1989). Design of modified atmosphere packaging systems: modeling oxygen concentrations within sealed packages of tomato fruits. Journal of Food Science, 54(6), 1413–1415. doi:10.1111/j.1365-2621.1989.tb05123.x.

Chadha, K. L., & Rajkot, M. S. (1967). Studies on the floral biology, fruit set and its retention and quality of some litchi varieties. Indian Journal of Horticulture, 27, 121–127.

Cornish-Bowden, A. (1979). Fundamentals of enzyme kinetics. London: Butterworth Ltd.

Dash, K. K. (2007). Modelling of respiration kinetics of fruits for control atmosphere storage and modified atmosphere storage. Unpublished M.Tech Thesis, Department of Agriculture and Food Engineering, Indian Institute of Technology, Kharagpur, India.

Fonseca, S. C., Oliveira, F. A. R., & Brecht, J. K. (2002). Modelling of respiration rate of fresh fruits and vegetables for modified atmosphere packages: a review. Journal of Food Engineering, 52, 99–119. doi:10.1016/S0260-8774(01)00106-6.

Giusti, A. M., Enrico, B., & Carlo, C. (2008). Exploring new frontiers in total food quality definition and assessment: from chemical to neurochemical properties. Food & Bioprocess Technology, 1, 130–142. doi:10.1007/s11947-007-0043-9.

Hagger, P. E., Lee, D. S., & Yam, K. L. (1992). Application of an enzyme kinetic based respiration model to closed system experiments for fresh produce. Journal of Food Process Engineering, 15, 143–157. doi:10.1111/j.1745-4530.1992.tb00148.x.

Hong, S. I., & Kim, D. M. (2001). Influence of oxygen concentration and temperature on respiratory characteristics of fresh cut green onion. International Journal of Food Science and Technology, 36(3), 283–289. doi:10.1046/j.1365–2621.2001.00456.x.

Kadam, S. S., & Deshpande, S. S. (1995). Lychee. In D. D. Salunkhe, & S. S. Kadam (Eds.), Handbook of fruit science and technology (pp. 435–443). New York: Marcel Dekker Inc.

Kader, A. A., Zagory, D., & Kerbel, E. L. (1989). Modified atmosphere packaging of fruits and vegetables. Critical Reviews in Food Science and Nutrition, 28(1), 1–30.

Kays, S. J. (1991). Metabolic Processes in Harvested Products Respiration. In Post Harvest Physiology of Perishable Plant Products. New York: Van Nostrand Reinhold Publication.

Lakakul, R., Beaudry, R. M., & Hernandez, R. J. (1999). Modelling respiration of apple slices in modified atmosphere packages. Journal of Food Science, 64(1), 105–110. doi:10.1111/j.1365-2621.1999.tb09870.x.

Lee, D. S., Hagger, P. E., Lee, J., & Yam, K. L. (1991). Model for fresh produce respiration in modified atmosphere based on principles of enzyme kinetics. Journal of Food Science, 56(6), 1580–1585. doi:10.1111/j.1365-2621.1991.tb08645.x.

Linus, U. O., Al-Ani, M. R., & Al-Shuaibi, Y. S. (2008). Physico-chemical Properties, Vitamin C Content, and Antimicrobial Properties of Pomegranate Fruit (Punica granatum L.). Food Bioprocess Technol. doi:10.1007/s11947-008-0095-5

Mahajan, P. V. (2001). Studies on Control atmosphere storage for apple and litchi using liquid nitrogen. Unpublished Ph.D. Thesis, Department of Agriculture and Food Engineering, Indian Institute of Technology, Kharagpur, India.

Mahajan, P. V., & Goswami, T. K. (2001). Enzyme kinetics based modeling of respiration rate for apple. Journal of Agricultural Engineering Research, 79(4), 399–406. doi:10.1006/jaer.2001.0718.

Mahajan, P. V., Oliveira, F. A. R., Montanez, J. C., & Frias, J. (2007). Development of user-friendly software for design of modified atmosphere packaging for fresh and fresh-cut produce. Innovative Food Science & Emerging Technologies, 8, 84–92. doi:10.1016/j.ifset.2006.07.005.

Martins, R. C., Lopes, V. V., Vicente, A. A., & Teixeira, J. A. (2008). Computational shelf-life dating: complex systems approaches to food quality and safety. Food & Bioprocess Technology, 1, 207–222. doi:10.1007/s11947-008-0071-0.

McLaughlin, C. P., & O’Beirne, D. (1999). Respiration rate of a dry coleslaw mix as affected by storage temperature and respiratory gas concentrations. Journal of Food Science, 64(1), 116–119. doi:10.1111/j.1365-2621.1999.tb09872.x.

Menon Rekha Ravindra, , & Goswami, T. K. (2008). Modelling of respiration rates of green matures mango under aerobic conditions. Biosystems Engineering, 99(2), 239–248. doi:10.1016/j.biosystemseng.2007.10.005.

Meyer, B. S., Anderson, D. B., Bohling, R. H., & Fratianne, D. G. (1973). Introduction to plant physiology (2nd ed.). Princeton, New Jersey, USA: Van Nostrand.

Peppelenbos, H. W., & Van’t Leven, J. (1996). Evaluation of four types of inhibition for modeling the influence of carbon dioxide on oxygen consumption fruits and vegetables. Postharvest Biology and Technology, 7, 27–40. doi:10.1016/0925-5214(96)80995-1.

Prasad, M. (1995). Development of modified atmosphere packaging system with permselective films for storage of red delicious apples. Unpublished Ph.D. Thesis, Department of Agriculture and Food Engineering, Indian Institute of Technology, Kharagpur, India.

Quevedo, R. A., Aguilera, J. M., & Pedreschi, F. (2008). Color of salmon fillets by computer vision and sensory panel. Food Bioprocess Technol. doi:10.1007/s11947-008-0106-6.

Raghavrao, D. (1983). Statistical technique: Agricultural and biological research. New Delhi: Oxford IBH Publishing Co.

Rangana, S. (1995). Hand book of analysis and quality control for fruits and vegetable products. New Delhi, India: Tata McGrow pub. Co.

Singh, H. P., & Babita, S. (2002). Lychee production in India. In M. K. Papdemetriou, & F. J. Dent (Eds.), Lychee production in the Asia-Pacific region (pp. 55–77). Bangkok, Thailand: Food and Agriculture Organization of the United Nations Regional Office for Asia and Pacific (FAO/RAP publications).

Sivakumar, D., & Korsten, L. (2006). Influence of modified atmosphere packaging and post harvest treatments on quality retention of litchi cv. Mauritius. Postharvest Biology and Technology, 41, 135–142. doi:10.1016/j.postharvbio.2006.03.007.

Talasila, P. C., Chau, K. V., & Brecht, J. K. (1992). Effects of gas concentrations and temperature on O2 consumption of strawberries. Transactions of ASAE, 35(1), 221–224.

Tian, S. P., Li, B. Q., & Xu, Y. (2005). Effect of O2 and CO2 concentrations on physiology and quality of litchi fruits in storage. Food Chemistry, 91, 659–63. doi:10.1016/j.foodchem.2004.06.038.

Toledo, R. T. (1991). Kinetics of chemical reactions in foods. Fundamentals of food processing engineering. New York: Chapman and Hall Inc.

Wills, R. B. H., McGlasson, W. B., Graham, D., Lee, T. H., & Hall, E. G. (1989). Post harvest: An introduction to the physiology and Handling of Fruits and Vegetables. New York: Chapman and Hall, Inc.

Yang, C. C., & Chinnan, M. S. (1988). Modeling the effect of O2 and CO2 on respiration and quality of stored tomatoes. Transactions of ASAE, 30(3), 920–925.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Mangaraj, S., Goswami, T.K. Modeling of Respiration Rate of Litchi Fruit under Aerobic Conditions. Food Bioprocess Technol 4, 272–281 (2011). https://doi.org/10.1007/s11947-008-0145-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11947-008-0145-z