Abstract

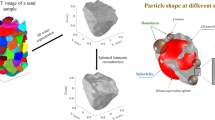

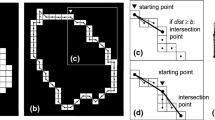

The morphological characteristics of mineral particles in ultrafine range have a significant influence on engineering processes but have not been extensively explored until now. In this study, the morphology of fine quartz particles produced in a planetary ball mill is considered using fractal geometry and stereometric tools in connection with particle size analysis. Structure functions and bidimensional shape factors were derived from numerical analysis of scanning electron micrographs using surface height functions and watershed algorithms. Secondary electron images were obtained from aliquots of clear and milky quartz samples ground up to 32 h. The fragmentation fractal dimension derived from the uniformity index of particle size distributions showed a distinct non-monotonical increase with the elapsed grinding time for each sample. Overall variations in fractal parameters (fractal dimension and corner frequency) and Feret’s diameter showed that the slowdown in particle size reduction and the onset of interparticle agglomeration occurred earlier for clear (monocrystalline) than for milky (polycrystalline) quartz. The onset of round-like agglomerates was also noticed with circular and round patterns. The loss of energy efficiency due to prolonged grinding processes was characterized by the decrease observed in the morphological fractal dimension.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

W. Peukert, H.C. Schwarzer, and F. Stenger, Chem. Eng. Process. 44, 245 (2005).

L. Opoczky, Powder Technol. 17, 1 (1977).

C. Knieke, M. Sommer, and W. Peukert, Powder Technol. 195, 25 (2009).

P. Prziwara, S. Breitung-Faes, and A. Kwade, Adv. Powder Technol. 29, 416 (2018).

V.V. Boldyrev, S.Y. Pavlov, and E.L. Goldberg, Int. J. Miner. Process. 44–45, 181 (1996).

Q. Zhang, J. Kano, and F. Saito, in Handbook of Powder Technology, vol 12. ed. by A.D. Salman, M. Ghadini, and M.J. Hounslow (Elsevier, Amsterdam, 2007), pp. 509–528.

P.L. Guzzo, F.B.M. de Barros, and A.A.A. Tino, Powder Technol. 342, 141 (2019).

T.P. Meloy, and M.C. Williams, Challenges in Mineral Processing (SMI, New York, 1994), pp. 207–221.

F. Podczeck, Powder Technol. 93, 47 (1997).

M.M. Ahmed, Int. J. Miner. Process. 94, 180 (2010).

D.L. Turcotte, J. Geophys. Res. 91, 1921 (1986).

B.H. Kaye, G.G. Clark, and Y. Liu, Part. Part. Syst. Charact. 9, 1 (1992).

A. Thomas, and L.O. Filippov, Int. J. Miner. Process. 57, 285 (1999).

A.A. Langroudi, I. Jefferson, K. O’hara-Dhand, and I. Smalley, Geomorphology 211, 1 (2014).

Y. Xu, Powder Technol. 323, 337 (2018).

G.J. Brown, N.J. Miles, and T.F. Jones, Miner. Eng. 9, 715 (1996).

H. Nagahama, Int. J. Rock Mech. 30, 469 (1993).

L. Little, M. Becker, J. Wiese, and A.N. Mainza, Miner. Eng. 82, 92 (2015).

P.L. Guzzo, in Rochas & Minerais Industriais: Usos e Aplicações, 2nd edn. ed. by A.B. Luz, and F.F. Lins (CETEM, Rio de Janeiro, 2008), pp. 681–721. (in Portuguese).

J. Götze, in Quartz: Deposits, Mineralogy and Analytics. ed. by J. Götze, and R. Möckel (Springer, Berlin Heidelberg, 2012), pp. 1–28.

K. Yildirim, H. Cho, and L.G. Austin, Powder Technol. 105, 210 (1999).

D.W. Fuerstenau, and A.-Z.M. Abouzeid, Int. J. Miner. Process. 67, 161 (2002).

L.M. Tavares, in Handbook of Powder Technology. ed. by A.D. Salman, M. Ghadini, and M.J. Hounslow (Elsevier, Amsterdam, 2007), pp. 3–68.

K.J. Murata, and M.B. Normann II., Am. J. Sci. 276, 1120 (1976).

P.L. Guzzo, F.B. Marinho de Barros, B.R. Soares, and J.B. Santos, Powder Technol. 368, 149 (2020).

J. Yue, and B. Klein, Miner. Eng. 18, 325 (2005).

A. Shrivastava, S. Sakthivel, B. Pitchumani, and A.S. Rathore, Powder Technol. 211, 46 (2011).

Ş Ţălu, Micro and Nanoscale Characterization of Three Dimensional Surfaces. Basics and Applications (Napoca Star Publishing House, Cluj-Napoca, 2015).

A. Thomas, and T.R. Thomas, J. Wave Mater. Interact. 3, 341 (1988).

E. Eberhardt, B. Stimpson, and D. Stead, Rock Mech. Rock Eng. 32, 81 (1999).

N.G. Yilmaz, Z. Karaca, R.M. Goktan, and C. Akal, Constr. Build. Mater. 23, 370 (2009).

S. Sadrai, J.A. Meech, D. Tromans, and F. Sassani, Miner. Eng. 24, 1053 (2011).

G.J. Brown, Miner. Eng. 10, 229 (1997).

H. Mio, J. Kano, and F. Saito, Chem. Eng. Sci. 59, 5909 (2004).

S. Liu, Q. Li, G. Xie, L. Li, and H. Xiao, Powder Technol. 295, 133 (2016).

C.O.R. Abbireddy, and C.R.I. Clayton, Proc. Inst. Civil Eng. Geotech. Eng. 162, 193 (2009).

Ş Ţălu, M. Bramowicz, S. Kulesza, A. Shafiekhani, A. Ghaderi, F. Mashayekhi, and S. Solaymani, Ind. Eng. Chem. Res. 54, 8212 (2015).

Acknowledgements

Grinding tests and particle size analysis were undertaken with the facilities provided by M.Sc. Filipe B. Marinho de Barros and M.Sc. Bruno R. Soares at Department of Mining Engineering, Federal University of Pernambuco (Recife, Brazil). PLG is grateful to CNPq (Conselho Nacional de Desenvolvimento Científico e Tecnológico, Brazil) for financial support (P: 420002/2016-02; P: 306374/2018-8; P: 310635/2021-7).

Author information

Authors and Affiliations

Contributions

PLG: Conceived the experimental work, methodology, SEM imaging, drafted the manuscript. ŞŢ: Conceived the study, revised the manuscript. SK: Fractal analysis, investigation, supervision. MB: Draft preparation, data analyses, investigation, validation. All authors have read and agreed to the published version of the manuscript.

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results. No author has a financial or proprietary interest in any material or method mentioned.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Guzzo, P.L., Ţălu, Ş., Kulesza, S. et al. A Fractal Description of Finely Ground Particles of Natural Quartz Using Particle Size and Image Analyses. JOM 75, 1333–1344 (2023). https://doi.org/10.1007/s11837-022-05687-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05687-1