Abstract

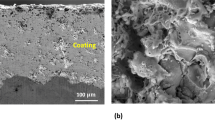

In this investigation, the AZ31 magnesium alloy was coated with a quaternary electroless Ni-Zn-Cu-P coating for less than 600 s, resulting in a coating thickness of 5 µm. To optimize the controllable coating parameters (nickel sulphate, zinc sulphate, and sodium hypophosphite), the Taguchi L27 orthogonal array was employed to maximize the microhardness of the coatings. By using these coating parameters as inputs and the microhardness of the coatings as an output, the applicability of an artificial neural network (ANN) was examined. To predict the microhardness of the coatings, ANNs with feed-forward back-propagation neural networks were trained using the Levenberg–Marquardt algorithm with 1 neuron for the first ANN, 2 neurons for the second, and so on up to ten ANN. The network with seven neurons in the hidden layer (ANN 3-7-1) shows the maximum correlation coefficient (R2), indicating that ANN 3-7-1 accurately predicts microhardness. For ANN 3-7-1, the root mean squared error and R2 were 8.8475 and 0.982, respectively. The surface morphology, composition, and crystallinity of the coatings were investigated and determined by field emission scanning electron microscopy, energy dispersive x-ray spectroscopy, and x-ray diffraction analysis.

Similar content being viewed by others

References

F. Goodwin, S. Guruswamy, K.U. Kainer, C. Kammer, W. Knabl, A. Koethe, G. Leichtfried, G. Schlamp, and R. Stickler, H. Warlimont, in Springer Handbook of Condensed Matter and Materials Data. ed. by W. Martienssen, and H. Warlimont (Springer, Berlin, 2005), pp. 161–430.

M.A. Taha, N.A. El-Mahallawy, R.M. Hammouda, and S.I. Nassef, J. Coatings Technol. Res. 7, 793. (2010).

Z.-M. Qiu, F. Zhang, J.-T. Chu, Y.-C. Li, and L. Song, Front. Mater. Sci. 14, 96. (2020).

B. Qingyou, Y. Yu, H. Liu, S. Bi, L. Cao, Q. Bai, and X. Teng, Int. J. Electrochem. Sci. 7, 8337. (2012).

M. Heshmati, D. Seifzadeh, P. Shoghi, and M. Gholizadeh-Gheshlaghi, Surf. Coatings Technol. 328, 20. (2017).

P. Zhou, W. Cai, Y. Yang, X. Li, T. Zhang, and F. Wang, Surf. Coatings Technol. 374, 103. (2019).

J. Liu, X. Wang, Z. Tian, M. Yuan, and X. Ma, Appl. Surf. Sci. 356, 289. (2015).

G. O. Mallory, J. B. Hajdu, American Electroplaters and Surface Finishers Society, in Electroless Plating: Fundamentals and Applications (American Electroplaters and Surface Finishers Society, Orlando, 1990).

J. Sudagar, J. Lian, and W. Sha, J. Alloys Compd. 571, 183. (2013).

W. Riedel, Electroless Nickel Plating (Publisher: ASM International; Finishing Publications, Metals Park, Ohio, Stevenage, England, 1991).

H. Larhzil, M. Cissé, R. Touir, M.E. Touhami, and M. Cherkaoui, Electrochim. Acta 53, 622. (2007).

W.L. Liu, S.H. Hsieh, W.J. Chen, and Y.C. Hsu, Appl. Surf. Sci. 255, 3880. (2009).

M. Oulladj, and D. Saidi, J Mater Sci. 34, 2437. (1999).

R. Wang, W. Ye, C. Ma, and C. Wang, Mater. Charact. 59, 108. (2008).

V. Kumar, B.B. Mandal, and B. Oraon, Mater. Today Proc. 59, 1183. (2022).

J.N. Balaraju, V.E. Selvi, V.K.W. Grips, and K.S. Rajam, Electrochim. Acta. 52, 1064. (2006).

P. Gadhari, and P. Sahoo, Procedia Mater. Sci. 6, 623. (2014).

S. Kundu, K. Das, and P. Sahoo, Mater. Today Proc. 5, 8547. (2018).

S. Sarkar, A. Mukherjee, R.K. Baranwal, J. De, C. Biswas, and G. Majumdar, J. Mech. Behav. Mater. 28, 153. (2019).

S. Sarkar, R.K. Baranwal, A. Mukherjee, I. Koley, C. Biswas, J. Haider, and G. Majumdar, Adv. Mater. Process. Technol. 6, 487. (2020).

I.A. Shozib, A. Ahmad, M.S.A. Rahaman, A.M. Abdul-Rani, M.A. Alam, M. Beheshti, and I. Taufiqurrahman, J. Mater. Res. Technol. 12, 1010. (2021).

ŞT. Güner, M.J. Diamantopoulou, K.P. Poudel, A. Çömez, and R. Özçelik, Comput. Electron. Agric. 192, 106596. (2022).

M. Zaimi and K. Noda, ECS Trans. 45, 3. (2013).

M. Ali Ahmadi, S. Zendehboudi, A. Lohi, A. Elkamel, and I. Chatzis, Geophys. Prospect. 61, 582. (2013).

M.A. Ahmadi, M.R. Ahmadi, S.M. Hosseini, and M. Ebadi, J. Pet. Sci. Eng. 123, 183. (2014).

M.A. Ahmadi and Z. Chen, Petroleum. 5, 271. (2019).

M.A. Ahmadi, A. Bahadori, and S.R. Shadizadeh, Fuel 139, 154. (2015).

M.A. Ahmadi, Math. Probl. Eng. 2015, 706897. (2015).

M.A. Ahmadi, R. Soleimani, M. Lee, T. Kashiwao, and A. Bahadori, Petroleum 1, 118. (2015).

S.R. Moosavi, D.A. Wood, M.A. Ahmadi, and A. Choubineh, Nat. Resour. Res. 28, 1619. (2019).

M. Ahmadi, and Z. Chen, J. Pet. Explor. Prod. Technol. 10, 2873. (2020).

M.H. Ahmadi, M. Alhuyi Nazari, R. Ghasempour, H. Madah, M.B. Shafii, and M.A. Ahmadi, Colloids Surfaces A Physicochem. Eng. Asp. 541, 154. (2018).

M. Ramezanizadeh, M.A. Ahmadi, M.H. Ahmadi, and M. Alhuyi Nazari, J. Therm. Anal. Calorim. 137, 307. (2019).

L.T. Le, H. Nguyen, J. Dou, and J. Zhou, Appl. Sci. 9, 2630. (2019).

J.F. Mas, and J.J. Flores, Int. J. Remote Sens. 29, 617. (2008).

G. Goudarzi, P.K. Hopke, and M. Yazdani, Chemosphere 283, 131285. (2021).

J. Garza-Ulloa, in Applied Biomechatronics Using Mathematical Models (Elsevier, 2018), pp. 373–524.

W. Yating, S. Bin, L. Lei, and H. Wenbin, J. Mater. Process. Technol. 205, 207. (2008).

X.F. Zou, Y.J. Hu, X.B. Long, and L.Y. Huang, Surfaces Interfaces 18, 100443. (2020).

S.Y.M. Vaghefi, and S.M.M. Vaghefi, Neural Comput. Appl. 20, 1055. (2011).

H. Beygi, H. Vafaeenezhad, and S.A. Sajjadi, Appl. Surf. Sci. 258, 7744. (2012).

M. Vijayanand, R. Varahamoorthi, and P. Kumaradhas, Mater. Today Proc. 49, 2239. (2022).

T.H. Priyanto, A. Insani, and R. Muslih, and Bharoto. J. Phys. Conf. Ser. 1436, 012061. (2020).

C. Gu, J. Lian, G. Li, L. Niu, and Z. Jiang, J. Alloys Compd. 391, 104. (2005).

K.G. Keong, W. Sha, and S. Malinov, J. Alloys Compd 334, 192. (2002).

I. Baskaran, T.S.N.S. Narayanan, and A. Stephen, Mater. Chem. Phys. 99, 117. (2006).

M. Cissé, M. Abouchane, T. Anik, K. Himm, R.A. Belakhmima, M. Ebn Touhami, R. Touir, and A. Amiar, Int. J. Corros. 2010, 246908. (2010).

M. Cherkaoui, A. Srhiri, and E. Chassaing, Plating Surf. Finish. 79, 68. (1992).

B. Oraon, G. Majumdar, and B. Ghosh, Mater. Des. 29, 1412. (2008).

M. Yan, H.G. Ying, and T.Y. Ma, Surf. Coatings Technol. 202, 5909. (2008).

B. Chandra Kandpal, J. Kumar, and H. Singh, Mater. Today Proc. 5, 18946. (2018).

L. Zhang, L. Sun, J.G. Han, and Y.H. Guo, J. Mater. Sci. Mater. Electron. 26, 2605. (2015).

D.C. Montgomery, Design and Analysis of Experiments (Wiley, Hoboken, NJ, 2017).

K. Ramesh, P. Baranitharan, and R. Sakthivel, Meas. J. Int. Meas. Confed. 131, 143. (2019).

A.M. Al-Swaidani and W.T. Khwies, Adv. Civ. Eng. 2018, 5207962. (2018).

Acknowledgements

The first author acknowledges AICTE (All India Council for Technical Education) for providing financial support for doing Ph.D. work under the AICTE-NDF (National Doctoral Fellowship) scheme at Jadavpur University.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Rauta, C.S., Majumdar, G. & Sarkar, S. Parametric Optimization of Microhardness of Electroless Ni-Zn-Cu-P Coating Using Taguchi Design and Artificial Neural Network. JOM 74, 4564–4574 (2022). https://doi.org/10.1007/s11837-022-05489-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-022-05489-5