Abstract

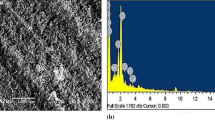

Glass fiber composites are emerging as alternatives to conventional materials. The aim of the present research is to investigate the three-body abrasion wear behavior of marble-powder-filled glass–epoxy composites in an abrasive environment. Three-body abrasion tests were conducted on composites using a rubber wheel abrasion tester as per ASTM-G-65 based on a Taguchi L16 orthogonal array design. The contribution of various control factors is identified based on analysis of variance tests. The abrasion resistance of the composites is observed to increase on addition of microsized marble powder. Two predictive models based on the regression equation and a neural network are developed to predict the abrasion loss of the hybrid composites. The artificial neural network model was found to be more convenient than the regression model to predict the wear loss of these composites. Microscopic observations of the abraded surfaces identified the different wear mechanisms.

Similar content being viewed by others

References

S.W. Tsai, Strength Characteristics of Composite Materials (Philco Co., Newport Beach, CA, 1965).

I. Hutchings and P. Shipway, Friction and Wear of Engineering Material, 2nd ed. (Butterworth-Heinemann, Elsevier, UK, 2017).

M.J. Neale and M. Gee, Guide to Wear Problems and Testing for Industry (William Andrew Publishing, New York, 2001).

P.J. Balu, ASM Handbook: Friction, Lubrication and Wear Technology (ASM International, Materials Park, OH, 1992).

U.S. Tewari, and A.P. Harsha, Polym. Test. 22, 403 (2003).

K. Kumaresan, G. Chandramohan, M. Senthilkumar, and B.J. Suresha, J. Reinf. Plast. Compos. 21, 1435 (2012).

J.D. Gate, Wear 214, 139 (1998).

S. Ray, A.K. Rout, and A.K. Sahoo, IOP Conf Ser. Mater. Sci. Eng. 225, 012097 (2017).

S. Bahadur, and V.K. Polineni, Wear 200, 95 (1996).

G.V. Kumar, R. Mageshvar, R. Rejath, S. Karthik, R. Pramod, and C.S.P. Rao, Compos. B Eng. 175, 107156 (2019).

B. Suresha, G. Chandramohan, P. Samapthkumaran, and S. Seetharamu, Mater. Sci. Eng. A 443, 285 (2007).

B. Suresha, G. Chandramohan, P. Sampathkumaran, and S. Seetharamu, Polym. Compos. 29, 1020 (2008).

B.K. Satapathy, and J. Bijwe, Wear 253, 787 (2002).

A.A. Cenna, J. Doyle, N.W. Page, A. Beehag, and P. Dastoor, Wear 240, 207 (2000).

M. Cirino, K. Friedrich, and R.B. Pipes, Composites 19, 383 (1988).

J.K. Lancaster, A Materials Science Handbook (North Holland, Amsterdam, 1992).

B.F. Yousif, and N.S.M. El-Tayeb, Tribol. Int. 43, 2365 (2010).

N. Chand, A. Naik, and S. Neogi, Wear 242, 38 (2000).

B.M. Sole, and A. Ball, Tribol. Int. 29, 457 (1996).

B.J. Briscoe, L.H. Yao, and T.A. Stolarski, Wear 108, 357 (1986).

X.C. Lu, S.Z. Wen, J. Tong, Y.T. Chen, and L.Q. Ren, Wear 193, 48 (1996).

M. Padhan, A. Gulhane, and J. Bijwe, Surf. Topol. Metrol. Proc. 8, 025013 (2020).

S. Ray, A.K. Rout, and A.K. Sahoo, Polym. Compos. 42, 424 (2021).

Minitab17. Minitab Inc., US Patent (2010).

G. Agarwal, A. Patnaik, and R.K. Sharma, SILICON 6, 155 (2014).

N. Mohan, S. Natarajan, and S.P. KumareshBabu, J. Appl. Polym. Sci. 124, 484 (2012).

B. Suresha, G. Chandramohan, and P.V. Mohanram, J. Polym. Compos. 30, 1106 (2009).

G. Agarwal, A. Patnaik, and R.K. Sharma, Int. J. Eng. Res. Appl. 2, 1148 (2012).

X. LiuJie, J.P. Davim, and R. Cardoso, J. Mater. Process. Technol. 189, 374 (2007).

S. Basavarajappa, K.V. Arun, and J.P. Davim, J. Min. Mater. Charact. Eng. 8, 379 (2009).

S.S. Moorthy, and K. Manonmani, Res. J. Appl. Sci. Eng. Technol. 7, 3356 (2014).

B. Shivamurthy, and M.S. Prabhuswamyc, J. Min. Mater. Charact. Eng. 8, 513 (2009).

Acknowledgements

The author declares that he has no conflicts of interest.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Ray, S. Parametric Optimization and Prediction of Abrasion Wear Behavior of Marble-Particle-Filled Glass–Epoxy Composites Using Taguchi Design Integrated with Neural Network. JOM 73, 2050–2059 (2021). https://doi.org/10.1007/s11837-021-04698-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04698-8