Abstract

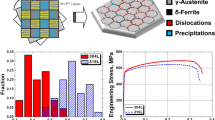

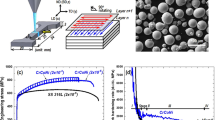

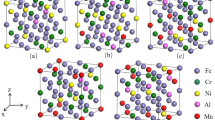

The thermal stability of dislocation cellular structures in three additively manufactured (AM) austenitic stainless steels (SSs), 316L SS, 304L SS, and Al modified 316L SS (316L(Al)), were studied. Minor alloying elements, Mo and Al, were found affecting the stability of the cellular structures in AM austenitic SS, resulting in a stability ranking of AM 316L SS > AM 304L SS > AM 316L(Al) SS. As a result, their abilities towards recrystallization also differed. Owing to the high stacking fault energy (SFE) due to Al addition, AM 316L(Al) SS had the least stable subgrain cellular structure and exhibited the lowest recovery temperature. Although 316L SS possessed slightly higher SFE than 304L SS, the pinning effect due to Mo segregation at the cellular walls in AM 316L SS significantly enhanced its thermal stability. While the low-SFE AM 316L SS and AM 304L SS recovered their cellular structures via the equiaxed cell growth, the dislocation cellular walls in high-SFE AM 316L(Al) SS continuously vanished along a preferred direction. The fast recovery of cellular structures led to recrystallization retardation. The Hall–Petch model was found incapable of correlating cell size to strength because of the continuous weakening of cellular walls during heat treatment.

Similar content being viewed by others

References

T. DebRoy, H.L. Wei, J.S. Zuback, T. Mukherjee, J.W. Elmer, J.O. Milewski, A.M. Beese, A. Wilson-Heid, A. De, and W. Zhang, Prog. Mater Sci. 92, 112 (2018).

Y.M. Wang, T. Voisin, J.T. McKeown, J. Ye, N.P. Calta, Z. Li, Z. Zeng, Y. Zhang, W. Chen, T.T. Roehling, R.T. Ott, M.K. Santala, P.J. Depond, M.J. Matthews, A.V. Hamza, and T. Zhu, Nat. Mater. 17, 63 (2018).

Y. Zhong, L. Liu, S. Wikman, D. Cui, and Z. Shen, J. Nulc. Mater. 470, 170 (2016).

R. Casati, J. Lemke, and M. Vedani, J. Mater. Sci. Technol. 32, 738 (2016).

P. Deng, M. Karadge, R.B. Rebak, V.K. Gupta, B.C. Prorok, and X. Lou, Addit. Manuf. 35, 101334 (2020).

M. Ghayoor, K. Lee, Y. He, C.-H. Chang, B.K. Paul, and S. Pasebani, Addit. Manuf. 32, 1 (2020).

M.A. Melia, H.-D.A. Nguyen, J.M. Rodelas, and E.J. Schindelholz, Corros. Sci. 152, 20 (2019).

W. Huang, Y. Zhang, W. Dai, and R. Long, Mater. Sci. Eng., A 758, 60 (2019).

L. Liu, Q. Ding, Y. Zhong, J. Zou, J. Wu, Y.-L. Chiu, J. Li, Z. Zhang, Q. Yu, and Z. Shen, Mater. Today 21, 354 (2018).

P. Krakhmalev, G. Fredriksson, K. Svensson, I. Yadroitsev, I. Yadroitsava, M. Thuvander, and R. Peng, Metals 8, 643 (2018).

E. Tascioglu, Y. Karabulut, and Y. Kaynak, Int. J. Adv. Manuf. Technol. 107, 1947 (2020).

N. Chen, G. Ma, W. Zhu, A. Godfrey, Z. Shen, G. Wu, and X. Huang, Mater. Sci. Eng., A 759, 65 (2019).

M.L. Montero Sistiaga, S, Nardone, C. Hautfenne, and J. Van Humbeeck, in Proc. Annu. Int. 27th 558 (2016).

D.A.H.R.D. Doherty, F.J. Humphreys, J.J. Jonas, D. JuulJensen, M.E. Kassner, W.E. King, T.R. McNelley, H.J. McQueen, and A.D. Rollett, Mater. Sci. Eng. A 238, 219 (1997).

I.Z. Awan and A.Q. Khan, J. Chem. Soc. Pak. 41, 1 (2019).

P.A.F. Stüwe and H.P.F. Siciliano Jr, Mater. Sci. Eng. A 333, 361 (2002).

N. Peranio, Y.J. Li, F. Roters, and D. Raabe, Mater. Sci. Eng., A 527, 4161 (2010).

W. Woo, J.S. Jeong, D.K. Kim, C.M. Lee, S.H. Choi, J.Y. Suh, S.Y. Lee, S. Harjo, and T. Kawasaki, Sci. Rep. 10, 1350 (2020).

X. Feaugas and C. Gaudin, Int. J. Plast 20, 643 (2004).

J.I.P. Bampton and M.H. Loretto, Acta Metall. 26, 39 (1978).

D. Molnár, X. Sun, S. Lu, W. Li, G. Engberg, and L. Vitos, Mater. Sci. Eng. A 759, 490 (2019).

P.R. Swann, Corrosion 19, 102t (1963).

R.R.P. Schramm, Metall. Mater. Trans. A 6, 1345 (1975).

R.A.W. Latanision, Metall. Mater. Trans. B 2, 505 (1971).

M.J. Whelan, P.B. Hirsch, R.W. Horne, and W. Bollmann, Proc. R. Soc. Lond. Ser. A. Math. Phys. Sci 240, 524 (1957).

S. Curtze, V.T. Kuokkala, A. Oikari, J. Talonen, and H. Hänninen, Acta Mater. 59, 1068 (2011).

T.G. Douglass and W.R. Roser, Corrosion 20, 15 (1964).

L.E. Murr, Thin Solid Films 4, 389 (1969).

G.R. Lehnhoff, K.O. Findley, and B.C. De Cooman, Scr. Mater. 92, 19 (2014).

J. Kim, S.-J. Lee, and B.C. De Cooman, Scr. Mater. 65, 363 (2011).

K.-T. Park, K.G. Jin, S.H. Han, S.W. Hwang, K. Choi, and C.S. Lee, Mater. Sci. Eng., A 527, 3651 (2010).

E.S. Essoussi and E. Essadiqi, Procedia Manuf. 22, 129 (2018).

S.M. Bruemmer, Corrosion 46, 699 (1990).

B.W. Bennett and H.W. Pickering, Metall. Mater. Trans. A 18, 1117 (1991).

R. Pascali, A. Benvenuti, and D. Wenger, Corrosion 40, 21 (1984).

R. Singh, I. Chattoraj, A. Kumar, B. Ravikumar, and P.K. Dey, Metall. Mater. Trans. A 34, 2441 (2003).

S.K. Mannan, R.K. Dayal, M. Vijayalakshmi, and N. Parvathavarthini, J. Nucl. Mater. 126, 1 (1984).

P.L. Andresen, Understanding and Mitigating Ageing in Nuclear Power Plants (Philadelphia: Woodhead Publishing, 2010), pp. 236–307.

N. Kamikawa, T. Hirochi, and T. Furuhara, Metall. Mater. Trans. A 50, 234 (2018).

T. Pinomaa, M. Lindroos, M. Walbrühl, N. Provatas, and A. Laukkanen, Acta Mater. 184, 1 (2020).

E. Getto, B. Tobie, E. Bautista, A.L. Bullens, Z.T. Kroll, M.J. Pavel, K.S. Mao, D.W. Gandy, and J.P. Wharry, JOM 71, 2837 (2019).

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, Metall. Trans. 2, 1979 (1971).

O. Takakuwa, Y. Kawaragi, and H. Soyama, J. Surf. Engd. Mater. Adv. Technol. 03, 262 (2013).

J.T. Busby, M.C. Hash, and G.S. Was, J. Nucl. Mater. 336, 267 (2005).

C.G. Rhodes and A.W. Thompson, Metall. Trans. A 8, 1901 (1977).

T. Yonezawa, K. Suzuki, S. Ooki, and A. Hashimoto, Metall. Mater. Trans. A 44, 5884 (2013).

Acknowledgements

This work was primarily sponsored by the National Institute of Standards and Technology under Contract NIST-70NANB18H220. TEM characterization was supported by the Idaho National Laboratory’s Laboratory Directed Research & Development (LDRD) Program under DOE Idaho Operations Office Contract DE-AC07-05ID14517 and US Department of Energy Nuclear Energy Enabling Technologies (NEET) Program under the Contract DE-NE0008428. DL and YZ gratefully acknowledge the financial support by the startup funding from the University of Nevada Reno.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Deng, P., Yin, H., Song, M. et al. On the Thermal Stability of Dislocation Cellular Structures in Additively Manufactured Austenitic Stainless Steels: Roles of Heavy Element Segregation and Stacking Fault Energy. JOM 72, 4232–4243 (2020). https://doi.org/10.1007/s11837-020-04427-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04427-7