Abstract

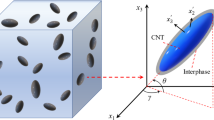

We suggest a two-stage approach for simulation of the elastic tensile modulus of polymer–carbon nanotube (CNT) nanocomposites including CNT networks, considering the hardening and percolating characters of the interphase region. In the first stage of the calculation, the Ouali equation is used to estimate the modulus of hypothetical particles consisting of CNTs and the nearby interphase. In the second stage, the Ouali model is applied to determine the modulus of the nanocomposite using the polymer medium and simulated particles obtained from the first stage of the process. The predictions obtained using the model are tested against experimental results for various samples. Subsequently, the effects of each simulation factor on the nanocomposite modulus are discussed. The presented technique is verified by the good agreement between the experimental results and model calculations, together with the normal effects of the parameters on the nanocomposite modulus. The use of CNTs with radius (R) > 40 nm and an interphase with depth (t) < 10 nm results in a 180% improvement in the modulus of the nanocomposite, but the overall modulus is increased by 400% when using the minimum R value of 10 nm and the maximum t value of 25 nm.

Similar content being viewed by others

References

A. Farahi, G.D. Najafpour, and A. Ghoreyshi, JOM 71, 285 (2019).

Y. Zare and K.Y. Rhee, JOM 71, 3980 (2019).

A. Adegbenjo, P. Olubambi, J. Westraadt, M. Lesufi, and M. Mphahlele, JOM 71, 2262 (2019).

S. Bibi, T. Yasin, S. Hassan, M. Riaz, and M. Nawaz, Mater. Sci. Eng., C 46, 359 (2015).

S. Arora, M. Rekha, A. Gupta, and C. Srivastava, JOM 1, 2590–2595 (2018).

Y. Zare and K.Y. Rhee, Compos. B Eng. 175, 107132 (2019).

Y. Zare, K.Y. Rhee, and S.J. Park, J. Biomed. Mater. Res. A 107, 2706 (2019).

I. Otaegi, N. Aranburu, M. Iturrondobeitia, J. Ibarretxe, and G. Guerrica-Echevarría, Polymers 11, 2059 (2019).

C.-F. Wang, W.-N. Wang, C.-H. Lin, K.-J. Lee, C.-C. Hu, and J.-Y. Lai, Polymers 11, 1183 (2019).

J. Wang, C. Cao, X. Chen, S. Ren, Y. Chen, D. Yu, and X. Chen, Polymers 11, 154 (2019).

A.M. Okoro, S.S. Lephuthing, S.R. Oke, O.E. Falodun, M.A. Awotunde, and P.A. Olubambi, JOM 71, 567 (2019).

A. Rostami, M. Vahdati, Y. Alimoradi, M. Karimi, and H. Nazockdast, Polymers 134, 143 (2018).

A. Rostami, F. Eskandari, M. Masoomi, M. Nowrouzi, and J. Oil, Gas Petrochem. Tech. 6, 28 (2019).

M. Hasanzadeh, R. Ansari, and M. Hassanzadeh-Aghdam, Mech. Mater. 129, 63 (2019).

M.K. Hassanzadeh-Aghdam, M.J. Mahmoodi, R. Ansari, and H. Mehdipour, Mech. Mater. 131, 121 (2019).

X. Cao, H. Dong, C.M. Li, L.A. Lucia, and J. Appl, Polym. Sci. 113, 466 (2009).

A. Rostami, M. Vahdati, and H. Nazockdast, Polym. Compos. 39, 2356 (2018).

M. Peydayesh, T. Mohammadi, O. Bakhtiari, and J. Ind, Eng. Chem. 69, 127 (2019).

R. Razavi, Y. Zare, and K.Y. Rhee, Polym. Compos. 40, 801 (2019).

Y. Zare, K.Y. Rhee, and S.-J. Park, Res. Phys. 15, 102406 (2019).

V. Favier, H. Chanzy, and J. Cavaille, Macromolecules 28, 6365 (1995).

Y. Zare and K.Y. Rhee, RSC Adv. 8, 30986 (2018).

S. Chen, M. Sarafbidabad, Y. Zare, and K.Y. Rhee, RSC Adv. 8, 23825 (2018).

S. Shekhar, E. Sajitha, V. Prasad, and S. Subramanyam, J. Appl. Phys. 104, 083910 (2008).

S. Chandran, N. Begam, and J. Basu, J. Appl. Phys. 116, 222203 (2014).

M.G. Ahangari, A. Fereidoon, M. Jahanshahi, and N. Sharifi, Compos. B Eng. 56, 450 (2014).

Y. Zare, H. Garmabi, and K.Y. Rhee, Polym. Test. 66, 189 (2018).

Y. Zare and K.Y. Rhee, Polym. Compos. 40, 4135 (2019).

W. Peng, S. Rhim, Y. Zare, and K.Y. Rhee, Polym. Compos. 40, 1117 (2019).

M.K. Hassanzadeh-Aghdam, M.J. Mahmoodi, and R. Ansari, Compos. B Eng. 168, 274 (2019).

Y. Zare, K.Y. Rhee, and S.-J. Park, Res. Phys. 15, 102562 (2019).

Z. Zhou, M. Sarafbidabad, Y. Zare, and K.Y. Rhee, J. Mech. Behav. Biomed. Mater. 86, 368 (2018).

A. Celzard, E. McRae, C. Deleuze, M. Dufort, G. Furdin, and J. Marêché, Phys. Rev. B 53, 6209 (1996).

N. Ouali, J. Cavaillé, and J. Perez, Plast. Rubber Compos. Process. Appl. 16, 55 (1991).

Y. Zare and K.Y. Rhee, J. Colloid Interface Sci. 506, 283 (2017).

A.P. Chatterjee, J. Appl. Phys. 100, 054302 (2006).

X.L. Ji, K.J. Jiao, W. Jiang, and B.Z. Jiang, Polym. Eng. Sci. 42, 983 (2002).

Y. Zare and K.Y. Rhee, J Alloys Compd. 793, 1 (2019).

N. Zhang, S. Li, L. Xiong, Y. Hong, and Y. Chen, Model. Simul. Mater. Sci. Eng. 23, 085010 (2015).

N. Zhang, S. Yang, L. Xiong, Y. Hong, and Y. Chen, J. Mech. Behav. Biomed. Mater. 53, 200 (2016).

L. Xiong and Y. Chen, Comput. Model. Eng. Sci. 24, 203 (2008).

W. Shao, Q. Wang, F. Wang, and Y. Chen, Carbon 44, 2708 (2006).

J. Ji, G. Sui, Y. Yu, Y. Liu, Y. Lin, Z. Du, S. Ryu, and X. Yang, J. Phys. Chem. C 113, 4779 (2009).

G.-X. Chen, H.-S. Kim, B.H. Park, and J.-S. Yoon, Polymer 47, 4760 (2006).

Y. Zare and K.Y. Rhee, JOM 71, 3989 (2019).

Y. Zare and K.Y. Rhee, J. Phys. Chem. Solids 131, 15 (2019).

Y. Zare, K.Y. Rhee, and J. Mater, Res. Tech. 9, 22 (2020).

M. Zappalorto, M. Salviato, and M. Quaresimin, Compos. Sci. Tech. 72, 49 (2011).

S.-Y. Fu, X.-Q. Feng, B. Lauke, and Y.-W. Mai, Compos. B Eng. 39, 933 (2008).

N. Jamalzadeh, S. Heidary, Y. Zare, and K.Y. Rhee, Polym. Test. 69, 1 (2018).

J.-M. Zhu, Y. Zare, and K.Y. Rhee, Colloids Surf. A Physicochem. Eng. Asp. 539, 29 (2018).

S.C. Baxter and C.T. Robinson, Compos. Sci. Tech. 71, 1273 (2011).

R. Qiao and L.C. Brinson, Compos. Sci. Tech. 69, 491 (2009).

A. Montazeri and R. Naghdabadi, J. Appl. Polym. Sci. 117, 361 (2010).

Y. Zare, J. Colloid Interface Sci. 471, 89 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zare, Y., Rhee, K.Y. Two-Stage Simulation of Tensile Modulus of Carbon Nanotube (CNT)-Reinforced Nanocomposites After Percolation Onset Using the Ouali Approach. JOM 72, 3943–3951 (2020). https://doi.org/10.1007/s11837-020-04223-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04223-3