Abstract

The present work investigates the influence of the laser power (P) and scanning speed (v) on the surface morphology and Vickers microhardness of single scan tracks formed by directed energy deposition (DED) to determine suitable parameter values for further in-depth investigation of additive and subtractive hybrid manufacturing (ASHM) of fabricated parts. The experimental results show that the depth and width of the melt pool depended significantly on both P and v. Furthermore, the anisotropic mechanical behavior of bulk 316L specimens fabricated by ASHM in the horizontal (H), edge (E), and vertical (V) directions relating to the build layers was also explored. The results show that the tensile strength of the specimens fabricated by ASHM in the H direction was higher than that of those built in the E or V direction, implying that the anisotropy originates from the unique thermal history of each component location owing to the layer-by-layer nature of the DED process.

Similar content being viewed by others

Abbreviations

- DED:

-

Directed energy deposition

- ASHM:

-

Additive and subtractive hybrid manufacturing

- AM:

-

Additive manufacturing

- SM:

-

Subtractive manufacturing

- FDM:

-

Fused deposition modelling

- SLM:

-

Selective laser melting

- 316LSS:

-

316L stainless steel

- LSCM:

-

Laser scanning confocal microscopy

- SEM:

-

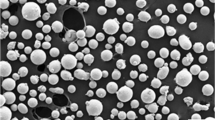

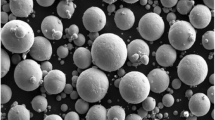

Field-emission scanning electron microscopy

- WEDM:

-

Wire electrical discharge machining

- UTS:

-

Ultimate tensile strength

- YS:

-

Yield strength

- ETF:

-

Elongation to fracture

- H:

-

Horizontal

- E:

-

Edge

- V:

-

Vertical

- Q v :

-

Powder feed rate

- P :

-

Laser power

- v :

-

Scanning speed

- h :

-

Layer thickness

- t :

-

Hatch spacing

- D :

-

Laser beam spot size

- f z :

-

Feed per tooth

- V Z :

-

Milling linear speed

- a p :

-

Amount of axis feed

- a e :

-

Amount of radial feed

- Ma:

-

Marangoni convection

- \( \Delta T \) :

-

Temperature gradient

- \( r_{\text{m}} \) :

-

Radius of the melt pool

- \( \alpha \) :

-

Thermal diffusivity of the melt pool

- \( T_{0} \) :

-

Room temperature

- \( {\text{AR}} \) :

-

Absorption rate

- \( k \) :

-

Heat transfer coefficient

- \( d \) :

-

Penetration depth

- T :

-

Operating temperature

- \( T_{\text{m}} \) :

-

Melting point

- \( \omega \) :

-

Surface tension

- \( \mu \) :

-

Dynamic viscosity of the melt pool

- m :

-

Atomic mass

- \( k_{\text{b}} \) :

-

Boltzmann’s constant

References

F. Weng, S.M. Gao, J.C. Jiang, J.J. Wang, and P. Guo, Addit. Manuf. 27, 474 (2019).

W. Woo, D.K. Kim, E.J. Kingston, V. Luzin, F. Salvemini, and M.R. Hill, Mater. Sci. Eng. A Struct. 744, 618 (2019).

B.C. Salzbrenner, J.M. Rodelas, J.D. Madison, B.H. Jared, L.P. Swiler, Y.L. Shen, and B.L. Boyce, J. Mater. Process. Technol. 241, 1 (2017).

T. Mukherjee, V. Manvatkar, A. De, and T. DebRoy, Scr. Mater. 127, 79 (2017).

J.H. Yi, J.W. Kang, T.J. Wang, X. Wang, Y.Y. Hu, T. Feng, Y.L. Feng, and P.Y. Wu, J. Alloys Compd. 786, 481 (2019).

L. Zhu, C. Ni, Z. Yang, and C. Liu, Precis. Eng. 57, 229 (2019).

S.S. Qu, Y.D. Gong, Y.Y. Yang, X.L. Wen, and G.Q. Yin, Ceram. Int. 45, 3059 (2019).

P.C. Priarone and G. Ingarao, J. Clean. Prod. 144, 57 (2017).

J.K. Watson and K.M.B. Taminger, J. Clean. Prod. 176, 1316 (2018).

W.C. Lee, C.C. Wei, and S.C. Chung, J. Mater. Process. Technol. 214, 2366 (2014).

M. Praniewicz, T. Kurfess, and C. Saldana, J. Manuf. Sci. E-T ASME 141, 1 (2019).

S. Zhang, Y.Z. Zhang, M. Gao, F.D. Wang, Q. Li, and X.Y. Zeng, Sci. Technol. Weld. JOI 24, 375 (2019).

T. Mishurova, S. Cabeza, K. Artzt, J. Haubrich, M. Klaus, C. Genzel, G. Requena, and G. Bruno, Materials 27, 4 (2017).

P. Mercelis and J.P. Kruth, Rapid Prototyp. J. 15, 5 (2006).

S.M. Yusuf, Y.F. Chen, R.P. Boardman, and S.F. Yang, Metals 7, 64 (2017).

D.D. Gu, W. Meiners, K. Wissenbach, and R. Poprawe, Int. Mater. Rev. 57, 133 (2012).

E. Liverani, S. Toschi, L. Ceschini, and A. Fortunato, J. Mater. Process. Technol. 249, 255 (2017).

B. AlMangour, D. Grzesiak, and J.M. Yang, Powder Technol. 319, 37 (2017).

W. Xiong, L. Hao, Y. Li, D.N. Tang, Q. Cui, Z.Y. Feng, and C.Z. Yan, Mater. Des. 170, 1 (2019).

B.L. Yan and L.D. Zhu, Int. J. Adv. Manuf. Technol. 102, 431 (2019).

X.H. Lu, Z.Y. Jia, X.X. Wang, Y.B. Liu, M.Y. Liu, Y.X. Feng, and S.Y. Liang, Measurement 145, 254 (2019).

Y.Y. Yang, Y.D. Gong, S.S. Qu, Y.L. Rong, Y. Sun, and M. Cai, Int. J. Adv. Manuf. Technol. 97, 2687 (2018).

A. Yadollahi, N. Shamsaei, S.M. Thompson, and D.W. Seely, Mater. Sci. Eng. A Struct. 644, 171 (2015).

C.L. Qiu, N.J.E. Adkins, and M.M. Attallah, Acta Mater. 103, 382 (2016).

I. Yadroitsev, P. Krakhmalev, and I. Yadroitsava, Addit. Manuf. 7, 45 (2015).

I. Yadroitsev, A. Gusarov, I. Yadroitsava, and I. Smurov, J. Mater. Process. Technol. 210, 1624 (2010).

D.H. Dai and D.D. Gu, Appl. Surf. Sci. 355, 310 (2015).

P. Wei, Z.Y. Wei, Z. Chen, J. Du, Y.Y. He, J.F. Li, and Y.T. Zhou, Appl. Surf. Sci. 408, 38 (2017).

J.Y. Zhang, D.D. Gu, Y. Yang, H.M. Zhang, H.Y. Chen, D.H. Dai, and K.J. Lin, Engineering 5, 736 (2019).

I. AlMangour, D. Grzesiak, T. Borkar, and J.M. Yang, Mater. Des. 138, 119 (2018).

Z.Q. Wang, T.A. Palmer, and A.M. Beese, Acta Mater. 110, 226 (2016).

Acknowledgements

The authors wish to acknowledge the support of the National Natural Science Foundation of China (No. 51775100) and the Fundamental Research Funds for the Central Universities (No. N180306001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Y., Gong, Y., Qu, S. et al. Additive and Subtractive Hybrid Manufacturing (ASHM) of 316L Stainless Steel: Single-Track Specimens, Microstructure, and Mechanical Properties. JOM 73, 759–769 (2021). https://doi.org/10.1007/s11837-020-04216-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-020-04216-2