Abstract

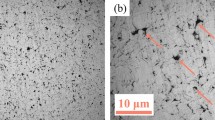

Magnesium matrix composites reinforced with 0.3 wt.% graphene were fabricated by semi-solid isothermal treatment using various reheating conditions and hot extrusion. The microstructures of the hot-extruded AZ31/graphene composites were clearly refined, with the finest grain size (7.05 µm) achieved after reheating at 610°C for 30 min. Energy-dispersive x-ray spectroscopy analysis revealed that increasing the reheating temperature promotes diffusion of the solute elements and affects the mechanical properties of the composite. The optimal mechanical properties were achieved after reheating at 620°C for 30 min, with a yield strength of 214.82 MPa and an ultimate tensile strength of 310.79 MPa. The significant improvement in the mechanical properties of the composite was mainly attributed to the refined grain size, uniformly redistributed solute elements, addition of graphene, and close interfacial bonding.

Similar content being viewed by others

References

Q.H. Yuan, G.H. Zhou, L. Lin, L. Yong, and L. Lan, Carbon 127, 177 (2018).

Y. Ali, D. Qiu, B. Jiang, F.S. Pan, and M.X. Zhang, J. Alloys Compd. 619, 639 (2015).

M. Rashad, F.S. Pan, J.Y. Zhang, and M. Asif, J. Alloys Compd. 646, 223 (2015).

Q. Chen, Y. Meng, Y.S. Yi, Y.Y. Wan, S. Sugiyama, and J. Yanagimoto, J. Alloys Compd. 774, 93 (2019).

I. Dinaharan, S.C. Vettivel, M. Balakrishnan, and E.T. Akinlabi, J. Magnes. Alloys 7, 155 (2019).

W.B. Yu, X.B. Li, M. Vallet, and L. Tian, Mech. Mater. 129, 246 (2019).

F. Khorasani, M. Emamy, M. Malekan, H. Mirzadeh, B. Pourbahari, T. Krajnák, and P. Minárik, Mater. Charact. 147, 155 (2019).

S.T. Manige, G. Harinath Gowd, and B. Chandra Mohan Reddy, J. Thin Films Coat. Sci. Technol. Appl. 5, 21 (2018).

N. Barri, A.R. Salasel, A. Abbasi, H. Mirzadeh, M. Emamy, and M. Malekan, Vacuum 164, 349 (2019).

M. Bastwros, G.Y. Kim, C. Zhu, K. Zhang, S. Wang, X.D. Tang, and X.W. Wang, Compos. B Eng. 60, 111 (2014).

F.Y. Chen, J.M. Ying, Y.F. Wang, S.Y. Du, Z.P. Liu, and Q. Huang, Carbon 96, 836 (2016).

Z. Li, Q. Guo, Z.Q. Li, G.L. Fan, D.B. Xiong, Y.S. Su, J. Zhang, and D. Zhang, Nano Lett. 15, 8077 (2015).

D.B. Xiong, M. Cao, Q. Guo, Z.Q. Tan, G.L. Fan, Z.Q. Li, and D. Zhang, ACS Nano 9, 6934 (2015).

W.J. Kim, T.J. Lee, and S.H. Han, Carbon 69, 55 (2014).

S.E. Shin, H.J. Choi, J.H. Shin, and D.H. Bae, Carbon 82, 143 (2015).

X. Du, W.B. Du, Z.H. Wang, K. Liu, and S.B. Li, Mater. Sci. Eng. A 711, 633 (2018).

S.L. Xiang, X.J. Wang, M. Gupta, K. Wu, X.S. Hu, and M.Y. Zheng, Sci. Rep. UK 6, 38824 (2016).

C.S. Goh, M. Gupta, J. Wei, and L.C. Lee, J. Compos. Mater. 41, 2325 (2007).

H.F. Wu, J.C. Li, X.X. Zhang, and L. Geng, Trans. Mater. Heat Treat. 39, 14 (2018).

Y.S. Yi, Y. Meng, D.Q. Li, S. Sugiyama, and J. Yanagimoto, J. Mater. Sci. Technol. 34, 1149 (2018).

H. Yan, Y.S. Rao, and R. He, J. Mater. Process. Technol. 214, 612 (2014).

Q. Chen, G. Chen, L.N. Han, N. Hu, F. Han, Z.D. Zhao, X.S. Xia, and Y.Y. Wan, J. Alloys Compd. 656, 67 (2016).

H. Asgharzadeh and M. Sedigh, J. Alloys Compd. 728, 47 (2017).

X. Gao, H.Y. Yue, E.J. Guo, S.L. Zhang, B. Wang, E.H. Guan, S.S. Song, and H.J. Zhang, Mater. Des. 94, 54 (2016).

H.Y. Xu, Z.S. Ji, M.L. Hu, and Z.Y. Wang, Trans. Nonferrous Met. Soc. 22, 2906 (2012).

M.H. Nai, J. Wei, and M. Gupta, Mater. Des. 60, 490 (2014).

K.P. So, I.H. Lee, D.L. Duong, T.H. Kim, S.C. Lim, K.H. An, and H.L. Young, Acta Mater. 59, 3313 (2011).

L. Zhang, Q.D. Wang, W.J. Liao, W. Guo, W.Z. Li, H.Y. Jiang, and W.J. Ding, Mater. Sci. Eng. A 689, 427 (2017).

Z.R. Zeng, Y.M. Zhu, R.L. Liu, S.W. Xu, C.H.J. Davies, J.F. Nie, and N. Birbilis, Acta Mater. 160, 97 (2018).

W.B. Hutchinson and M.R. Barnett, Scr. Mater. 63, 737 (2010).

S.R. Agnew, D.W. Brown, and C.N. Tome, Acta Mater. 54, 4841 (2006).

O. Muransky, D.G. Carr, M.R. Barnett, E.C. Oliver, and P. Sittner, Mater. Sci. Eng. A 496, 14 (2008).

M.R. Barnett, Z. Keshavarz, and X. Ma, Metall. Mater. Trans. 37, 2283 (2006).

J.W. Luste, M. Thumann, and R. Baumann, Metal. Sci. J. 9, 853 (1993).

W.S. Miller and F.J. Humphreys, Scr. Metall. Mater. 25, 33 (1991).

P.B. Li and T.J. Chen, Powder Metall. 59, 288 (2016).

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Nos. 51704087 and 51574100) and University Nursing Program for Young Scholars with Creative Talents in Heilongjiang Province (UNPYSCT-2016033).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yang, Z., Xu, H., Wang, Y. et al. Investigation of the Microstructure and Mechanical Properties of AZ31/Graphene Composite Fabricated by Semi-solid Isothermal Treatment and Hot Extrusion. JOM 71, 4162–4170 (2019). https://doi.org/10.1007/s11837-019-03736-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03736-w