Abstract

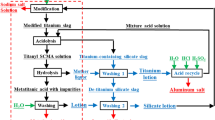

This research mainly focuses on recovery of titanium from Ti-bearing blast furnace slag using the process of alkali calcination, water leaching, and acid hydrolysis. The Ti-bearing blast furnace slag contained approximately 24% SiO2, 12.73% Al2O3, and 20.74% TiO2. The main minerals in the slag were perovskite, diopside, and spinel. In the calcination process, the chemical products were NaAlO2, Na2SiO3, Na2CaSiO4, and Na2TiO3. In the leaching process, NaAlO2 and Na2SiO3 dissolved in water, Na2CaSiO4 remained in the water-leached product, and Na2TiO3 was hydrolyzed to an amorphous state. After alkali calcination and water leaching, 45% of SiO2 and 83% of Al2O3 were removed, while the TiO2 content increased to 36.13%. The extraction rate of titanium was 91.21% after hydrolysis by dilute sulfuric acid at 120°C for 2 h of the water-leached product, and nano-anatase TiO2 was obtained by hydrolysis and calcination of the resulting titanyl sulfate solution.

Similar content being viewed by others

References

T. Jesionowski, A. Krysztafkiewicz, and A. Dec, Physiochem. Prob. Miner. Process. 35, 195 (2001).

T.A. Rahim, K. Takahashi, M. Yamada, and M. Fukumoto, Mater. Trans. 57, 1345 (2016).

J.H. Braun, A. Baidins, and R.E. Marganski, Prog. Org. Coat. 20, 105 (1992).

X.F. Lei, X.X. Xue, and H. Yang, Trans. Nonferrous Met. Soc. China 22, 1771 (2012).

M. Guéguin and F. Cardarelli, Miner. Process. Extr. Metall. Rev. 28, 1 (2007).

F. Valighazvini, F. Rashchi, and R.K. Nekouei, Ind. Eng. Chem. Res. 52, 1723 (2013).

X.H. Liu and Z.T. Sui, Chin. J. Nonferrous Met. 12, 1281 (2002).

Z.Q. Huang, M.H. Wang, X.H. Du, and Z.T. Sui, J. Mater. Sci. Technol. China 19, 191 (2003).

Y. Xiong, C. Li, B. Liang, and J. Xie, Chin. J. Nonferrous Met. 18, 557 (2008).

N.X. Fu, T.P. Lou, X.H. Du, and Z.T. Sui, J. Northeast. Univ. 33, 698 (2012).

Y. Peng, Titan. Ind. Prog. 22, 44 (2005).

T.Y. Xue, L. Wang, T. Qi, J.L. Chu, J.K. Qu, and C.H. Liu, Hydrometallurgy 95, 22 (2009).

Y. Feng, J.G. Wang, L.N. Wang, T. Qi, T.Y. Xue, and J.L. Chu, Rare Met. 28, 564 (2009).

Y.F. Han, T.C. Sun, J. Li, T. Qi, L.N. Wang, and J.K. Qu, Int. J. Miner. Metall. Mater. 19, 205 (2012).

D.S. Chen, L.S. Zhao, Y.H. Liu, T. Qi, J.C. Wang, and L.N. Wang, J. Hazard. Mater. 244, 588 (2013).

Q.R. Shen, J.H. Li, T.T. Qian, Q. Zhang, and H.Y. Zhang, Acta Petrol. Mineral. 32, 889 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

He, S., Peng, T. & Sun, H. Titanium Recovery from Ti-Bearing Blast Furnace Slag by Alkali Calcination and Acidolysis. JOM 71, 3196–3201 (2019). https://doi.org/10.1007/s11837-019-03575-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03575-9