Abstract

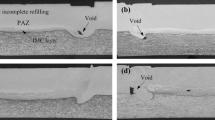

To reduce intermetallic compounds (IMCs), dissimilar Mg/Al alloys were joined by solid-state friction spot welding. No incomplete refilling was observed when Al sheet served as the upper sheet. Almost no IMCs formed at the sleeve-affected zone even though the sleeve plunged during welding. A 530-µm-thick Al12Mg17 layer formed at the center of the Al/Mg joint due to a large amount of liquid phase formed during welding. Only a 5-µm-thick Al3Mg2 layer formed in the Mg/Al joint because the oxide film on the Al sheet was difficult to break. The Al/Mg joint exhibited much higher lap shear failure load even though it had a thicker IMC layer. The joint formation mechanism was studied.

Similar content being viewed by others

References

W. Guo, G. You, G. Yuan, and X. Zhang, J. Alloys Compd. 695, 3267 (2017).

M.R. Islam, M. Ishak, L.H. Shah, S.R.A. Idris, and C. Meriç, Int. J. Adv. Manuf. Technol. 88, 2773 (2017).

Z. Li, Z. Xu, D. Zhu, Z. Ma, and J. Yan, J. Mater. Process. Technol. 255, 524 (2018).

Z. Xu, Z. Li, B. Peng, and Z. Ma, J. Yan. Mater. Lett. 228, 72 (2018).

Z. Xu, Z. Li, J. Li, Z. Ma, and J. Yan, Ultrason. Sonochem. 46, 79 (2018).

M. Jafarian, A. Khodabandeh, and S. Manafi, Mater. Des. 65, 160 (2015).

U.F.H. Suhuddin, V. Fischer, and J.F. dos Santos, Scr. Mater. 68, 87 (2013).

U. Suhuddin, V. Fischer, F. Kroeff, and J.F. dos Santos, Mater. Sci. Eng., A 590, 384 (2014).

A. Kostk, R.S. Coelho, J.F. dos Santos, and A.R. Pyzalla, Scr. Mater. 60, 953 (2009).

Z. Lai, C. Pan, H. Du, X. Chen, R. Xie, L. Liu, W. Long, and G. Zou, Sci. Technol. Weld. Join. 23, 19 (2018).

J. Zhang, G. Luo, Y. Wang, Q. Shen, and L. Zhang, Mater. Lett. 83, 189 (2012).

X. Dai, H. Zhang, H. Zhang, and J. Liu, J. Feng. Mater. Lett. 178, 235 (2016).

Y.C. Chen, H.J. Liu, and J.C. Feng, Mater. Sci. Eng., A 420, 21 (2006).

H.J. Liu, H. Fujii, M. Maeda, and K. Nogi, J. Mater. Process. Technol. 142, 692 (2003).

Z. Ma, Y. Jin, S. Ji, and X. Meng, J. Mater. Sci. Technol. 35, 94 (2019).

Y. Huang, L. Wan, Z.L. Lv, S.X. Lv, L. Zhou, and J.C. Feng, Sci. Technol. Weld. Join. 21, 638 (2016).

N. Li, W. Li, X. Yang, Y. Xu, and A. Vairis, Surf. Coat. Technol. 349, 1069 (2018).

M.D. Tier, T.S. Rosendo, J.F. dos Santos, N. Huber, J.A. Mazzaferro, C.P. Mazzaferro, and T.R. Strohaecker, J. Mater. Process. Technol. 213, 997 (2013).

J.A.E. Mazzaferro, T.S. Rosendo, C.C.P. Mazzaferro, F.D. Ramos, M.A.D. Tier, T.R. Strohaecker, and J.F. dos Santos, Soldag. Insp. 14, 238 (2009).

Z.K. Shen, X.Q. Yang, Z.H. Zhang, L. Cui, and T. Li, Mater. Des. 44, 476 (2013).

Z. Li, Z. Xu, L. Zhang, and Z. Yan, Mater. Sci. Technol. 33, 1626 (2017).

Y. Chen, J. Chen, B.S. Amirkhiz, M.J. Worswick, and A.P. Gerlich, Sci. Technol. Weld. Join. 20, 494 (2015).

Z. Xu, Z. Li, S. Ji, and L. Zhang, J. Mater. Sci. Technol. 34, 878 (2018).

Y.Q. Zhao, H.J. Liu, S.X. Chen, Z. Lin, and J.C. Hou, Mater. Des. 62, 40 (2014).

Z. Li, S. Ji, Y. Ma, P. Chai, Y. Yue, and S. Gao, Int. J. Adv. Manuf. Technol. 86, 1925 (2016).

Q. Chu, W.Y. Li, X.W. Yang, J.J. Shen, A. Vairis, W.Y. Feng, and W.B. Wang, J. Mater. Sci. Technol. 34, 1739 (2018).

E. Fereiduni, M. Movahedi, and A.H. Kokabi, Sci. Technol. Weld. Join. 21, 466 (2016).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chai, P., Yang, K., Ji, S. et al. Joining Dissimilar Mg/Al Alloys by Solid-State Friction Spot Welding. JOM 71, 1760–1767 (2019). https://doi.org/10.1007/s11837-019-03401-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03401-2