Abstract

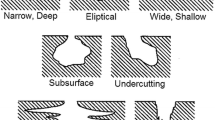

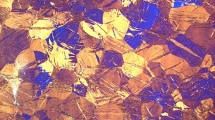

Precipitation hardening in Mg-Y-Nd alloys (WE-type) is based on finely dispersed particles offering an effective strengthening mechanism to achieve high strength at moderate ductility. However, these particles often affect corrosion by being more noble than the matrix. Biodegradable implant materials should show a corrosion rate fit to its application but should be free of pitting corrosion. Especially deep and narrow pits act as notches and cause increased mechanical stress leading into early failure. WE43 has already shown to have an acceptable biological response. In this study, two Mg-Y-Nd-Gd-Dy alloys, WE32 and WE33, in extruded, solution and precipitation heat-treated conditions have been investigated. The difference in alloy composition is not very high. Solution heat treatment (T4) causes grain growth and strength loss. The ageing response to peak hardness depends on the temperature. A rather short ageing response was observed for 250°C, and highest hardness has been found for 200°C at longer ageing time but higher hardness compared to 250°C. Grain growth during ageing is not significant. The higher alloyed alloy WE33 shows better mechanical strength, but less ductility. Corrosion was evaluated with immersion and potentiodynamic polarization in Ringer Acetate solution. The corrosion rate strongly depends on the alloy and heat-treatment condition as well as on the test method. The highest corrosion rate is observed in the solution-treated condition. The peak aged alloy shows the lowest corrosion rate, but non-uniform corrosion and has been evaluated by the pitting factor.

Similar content being viewed by others

References

D. Zhao, F. Witte, F. Lu, J. Wang, J. Li, and L. Qin, Biomaterials 112, 287 (2016).

A.D. Sudholz, K. Gusieva, X.B. Chen, B.C. Muddle, M.A. Gibson, and N. Birbilis, Corros. Sci. 53, 2277 (2011).

M.P. Staiger, A.M. Pietak, J. Huadmai, and G. Dias, Biomaterials 27, 1728 (2006).

N. Hort, Y. Huang, D. Fechner, M. Störmer, C. Blawert, F. Witte, C. Vogt, H. Drücker, R. Willumeit, K.U. Kainer, and F. Feyerabend, Acta Biomater. 6, 1714 (2010).

H. Kalb, A. Rzany, and B. Henzel, Corros. Sci. 57, 122 (2012).

J.M. Seitz, A. Lucas, and M. Kirschner, JOM 68, 1177 (2016).

C. Rapetto and M. Leoncini, J. Thorac. Dis. 9, 903 (2017).

Magnesium Elektron UK, data sheet 467.

D. Tolnai, C.L. Mendis, A. Stark, G. Szakacs, B. Wiese, K.U. Kainer, and N. Hort, Mater. Lett. 102–103, 62 (2013).

B. Smola, I. Stulikova, F. von Buch, and B.L. Mordike, Mater. Sci. Eng., A 324, 113 (2002).

L.L. Rokhlin, T.V. Dobatkina, N.I. Nikitina, and I.E. Tarytina, Met. Sci. Heat Treat. 52, 588 (2011).

Y.H. Kang, D. Wu, and R.H.E. Chen, J. Magnes. Alloys 2, 109 (2014).

F. Feyerabend, J. Fischer, J. Holtz, F. Witte, R. Willumeit, H. Drücker, C. Vogt, and N. Hort, Acta Biomater. 6, 1834 (2010).

L. Yang, N. Hort, D. Laipple, D. Höche, Y. Huang, K.U. Kainer, R. Willumeit, and F. Feyerabend, Acta Biomater. 9, 8475 (2013).

ASTM Standard G46-94, Standard Guide for Examination and Evaluation of Pitting Corrosion (Washington, DC: ASTM, 1994).

R.W. Revie and H.H. Uhlig, Corrosion and Corrosion Control (Hoboken: Wiley, 2008), p. 17.

Z. Ahmad, Principles of Corrosion Engineering and Corrosion Control (Oxford: Butterworth-Heinemann, 2006), p. 266.

F. Witte, J. Fischer, J. Nellesen, C. Vogt, J. Vogt, T. Donath, and F. Beckmann, Acta Biomater. 6, 1792 (2010).

V. Kree, J. Bohlen, D. Letzig, and K.U. Kainer, Pract. Metallogr. 41, 233 (2004).

N. Li, C. Guo, Y.H. Wu, Y.F. Zheng, and L.Q. Ruan, Corros. Eng., Sci. Technol. 47, 346 (2012).

P. Maier, S. Gavras, M. Freese, G. Schott, and N. Hort, in Proceedings of the 11th International Conference on Magnesium Alloys and their Applications: Mg2018, Old Windsor, UK (2018).

Y. Zheng, Magnesium Alloys as Degradable Biomaterials (Boca Raton: CRC Press, 2015), p. 345.

S. Gorsse, C.R. Hutchinson, B. Chevalier, and J.F. Nie, J. Alloys Compd. 392, 253 (2005).

P. Maier, R. Peters, C.L. Mendis, S. Müller, and N. Hort, JOM 68, 1183 (2016).

D. Orlov, K.D. Ralston, N. Birbilis, and Y. Esttin, Acta Mater. 59, 6176 (2011).

L.G. Bland, B.C. Rincon Troconis, R.J. Santucci, J.M. Fitz-Gerald, and J.R. Scully, Corrosion 72, 1226 (2016).

X. Ma, Q. Jiang, Y. Li, and B.R. Hou, Int. J. Electrochem. (2016)

P. Maier, M. Bechly, and N. Hort, in Contributed Papers from Materials Science and Technology—MS&T17, p. 76 (2017)

Acknowledgements

The authors thank the Extrusion Center Berlin in Germany for extruding the bars and acknowledge the support of Hartmut Habeck and Benjamin Clausius from UAS Stralsund. Julia Bode from TU Bergakademie Freiberg, Germany, is thanked for ICP-OES measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Maier, P., Lauth, N., Mendis, C.L. et al. Mechanical and Corrosion Properties of Two Precipitation-Hardened Mg-Y-Nd-Gd-Dy Alloys with Small Changes in Chemical Composition. JOM 71, 1426–1435 (2019). https://doi.org/10.1007/s11837-019-03359-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03359-1