Abstract

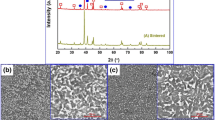

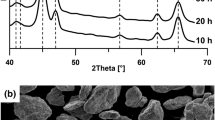

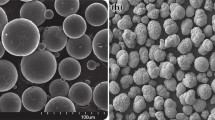

TiAl-based alloys have been regarded as potential substitute materials for heavy Ni super-alloys. To understand the relationship of the processing-microstructure-hot deformation behavior of TiAl-based alloys fabricated via the spark plasma sintering technique, alloys were sintered at a temperature range of 1150–1350°C. Subsequently, isothermal compression tests were carried out at 1125°C with a strain rate of 0.1 s−1. The pre-alloyed powders, which showed dendritic structures, were mainly composed of α2 phase and a few of γ phase. Alloys composed of near gamma, duplex, and fully lamellar microstructures were obtained after sintering at 1150–1250°C, 1300°C, and 1350°C, respectively. The compressive peak stress increased with increasing sintering temperature, and the alloy sintered at 1250°C exhibited a better hot deformability. Moreover, dynamic recrystallization and phase transformation of α2 → γ occurred during isothermal compression.

Similar content being viewed by others

References

F. Appel, H. Clemens, and F.D. Fischer, Prog. Mater. Sci. 81, 55 (2016).

M. Bünck, T. Stoyanov, J. Schievenbusch, H. Michels, and A. Gußfeld, JOM 69, 2565 (2017).

W. Xu, X. Jin, K. Huang, Y. Zong, S. Wu, X. Zhong, F. Kong, D. Shan, and S. Nutt, Mater. Sci. Eng. A 705, 200 (2017).

G. Wegmann, R. Gerling, F.P. Schimansky, H. Clemens, and A. Bartels, Intermetallics 10, 511 (2002).

Z. Trzaska, A. Couret, and J.P. Monchoux, Acta Mater. 118, 100 (2016).

D. Wang, R. Zhang, H. Yuan, and J. Qiang, JOM 69, 1824 (2017).

H.Z. Niu, Y.J. Su, Y.S. Zhang, D.L. Zhang, J.W. Lu, W. Zhang, and P.X. Zhang, Intermetallics 66, 96 (2015).

B. Tang, L. Cheng, H. Kou, and J. Li, Intermetallics 58, 7 (2015).

C. Zhang, K. Zhang, and G. Wang, Intermetallics 18, 834 (2010).

L. Cheng, J. Li, X. Xue, B. Tang, H. Kou, and E. Bouzy, Intermetallics 75, 62 (2016).

Y. Chu, J. Li, F. Zhao, B. Tang, and H. Kou, Mater. Sci. Eng. A 725, 466 (2018).

H. Zhou, F. Kong, X. Wang, and Y. Chen, Intermetallics 81, 62 (2017).

Y. Cao, H. Di, J. Zhang, J. Zhang, T. Ma, and R.D.K. Misra, Mater. Sci. Eng. A 585, 71 (2013).

Y. Zong, D. Wen, Z. Liu, and D. Shan, Mater. Des. 91, 321 (2016).

T. Sakai, A. Belyakov, R. Kaibyshev, H. Miura, and J.J. Jonas, Prog. Mater. Sci. 60, 130 (2014).

Acknowledgements

This work was supported by the Natural Science Foundation of China (Grant Nos. 51675125, 51675126) and the Natural Science Foundation of Heilongjiang Province (No. DC2013C048).

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Shi, C., Han, M., Zhang, K. et al. Effects of Sintering Temperature on Microstructure Evolution and Hot Deformation Behavior of TiAl-Based Alloys Prepared by Spark Plasma Sintering. JOM 70, 2739–2745 (2018). https://doi.org/10.1007/s11837-018-3100-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3100-0