Abstract

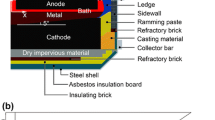

The energy consumption for aluminum production by the Hall-Héroult process has been significantly improved during the last few decades. This has been achieved mainly as a result of improved cell design and suitable process control strategies that have allowed higher cell currents and smaller anode-cathode distance (ACD). Without taking suitable corrective actions, operations at lower ACD conditions can negatively impact aluminum re-oxidation, by-pass current, alumina dissolution and anode effect rates. Superior operational practices are therefore required to maintain acceptably low instability levels along with lower specific energy consumption. This paper discusses anode effect fundamentals and greenhouse gas emissions in relation with industrial cells operating at low ACD at the Aluminerie Alouette plant in Quebec.

Similar content being viewed by others

References

S. Ponzák, “Formation et évolution des Bulles de Gaz au-Dessous de l’anode Dans une Cuve d’électrolyse d’aluminum” (Ph.D. Thesis, Université du Québec à Chicoutimi, 2000).

J. Thonstad, Electrochimica Acta, 12(9) (1967), pp. 1219–1226.

M. Rolin and M. Rey, Bull. Soc. Chim. Fr. (1966), p. 2794.

S. Jarek and J. Thonstad, Electrochimica Acta, 32(5) (1987), pp. 743–747.

A.J. Calandra, C.E. Castellano, and C.M. Ferro, Electrochimica Acta, 24(4) (1979), pp. 425–437.

M.M.R. Dorreen, “Cell Performance and Anodic Processes in Aluminum Smelting Studied by Product Gas Analysis” (Ph.D. Thesis, University of Auckland, 2000).

Climate Change 1995, available at www.ipcc.ch/pdf/climate-changes-1995/ipcc-2nd-assessment/2ndassessment-en.pdf (December 1995).

P. Coursol, P.J. Makey, and C. Dias, Proceedings of the Copper 2010 Conference, ed. Jens Harre (Clausthal-Zellerfeld, Germany: GDMB, 2010), pp. 649–668.

J. Marks, “Protocol for Measurement of Tetrafluoromethane (CF4) and Hexafluoroethane (C2F6) Emissions from Primary Aluminum Production,” available at www.epa.gov/aluminum-pfc/documents/measureprotocol.pdf (April 2011).

J. Marks, Aluminum 2006, 45th Annual Conference of Metallurgists of CIM (Montreal, Canada: CIM, 2006), pp. 79–89.

S. Fardeau, B. Sulmont, P. Vellemans, and C. Ritter, Light Metals 2010, ed. John A. Johnson (Warrendale, PA: TMS, 2010), pp. 495–500.

Additional information

Pascal Coursol, Technology Manager, Patrick Coulombe, Casting Center Manager, Serge Gosselin, Reduction Manager, and Dany Lavoie, Technical Superintendant-Reduction, are all with Aluminerie Alouette. Jean-Marc Simard, Exaprom, and Jerry Marks, J. Marks and Associates, are independent consultants. Sylvain Fardeau is with the ALPSYS development team at Rio Tinto Alcan.

Rights and permissions

About this article

Cite this article

Coursol, P., Coulombe, P., Gosselin, S. et al. Impact of operations at low anode-cathode distance on energy consumption and greenhouse gas emissions at Aluminerie Alouette. JOM 63, 109–115 (2011). https://doi.org/10.1007/s11837-011-0121-3

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-011-0121-3