Abstract

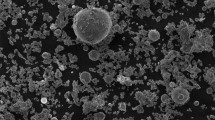

In the past, the mechanisms of corrosion in refractory materials used in the flue wall of anode baking furnaces have been poorly understood. To better understand the processes of degradation, a study of corroded refractories from anode baking furnaces was conducted. This study found that all refractory bricks contain fine andalusite particles in the matrix and fireclay as aggregates. The first stage of corrosion is the penetration of gaseous sodium, coming from recycled anodes, through the porosity of materials. Then, at high temperature, sodium becomes oxidized and is included in the liquid phase. The sodium-rich liquid phase corrodes the refractory material, in particular mullite networks. To understand why the andalusite mineral is used in the refractory materials, a corrosion test able to simulate the gaseous corrosion of materials at laboratory scale was developed. Several recipes, composed of andalusite or fireclay, were submitted to the corrosion test. The microstructural observations showed that the matrix is more sensitive to corrosion. Thus, the use of a raw material such as andalusite in the matrix is advised in order to reduce the gaseous sodium corrosion of fireclay based bricks.

Similar content being viewed by others

References

J.P. Ildefonse et al., “Mullitization of Andalusite in Bricks and Castables,” UNITECR’97, 5th Biennial Worldwide Conference on Refractories, vol. II (Westerville, OH: American Ceramic Society, 1997), pp. 899–907.

J. Butter and Aart Bongers, “Alterations of Anode Baking Furnace Bricks during Operation,” Light Metals 1995, ed. J. Evans (Warrendale, PA: TMS, 1995), pp. 633–639.

M.L. Bouchetou et al., “Production of High Mullite Content Material from Natural Andalusite: Influence of Grain Size,” Refractories Applications and News, 10(5) (September 2005), pp. 16–21.

F. Brunk, “Corrosion and Behavior of Fireclay Bricks used in the Flues of Open Anode Baking Furnace,” Light Metals 1995, ed. J. Evans (Warrendale, PA: TMS, 1995), pp. 641–646.

J. Butter, “Recycling of Anode Baking Furnace Refractory Bricks,” Light Metals 1994, ed. U. Mannweiler (Warrendale, PA: TMS, 1994), pp. 633–640.

O.J. Silijan, “Influence of Sodium on Refractory Behavior in Aluminium Production,” Advances in Refractories for the Metallurgical Industries IV, ed. C. Allaire and M. Rigaud (Montreal, Canada: Canadian Institute of Mining, Metallurgy and Petroleum, 2004), pp. 115–132.

P. Prigent, M.L. Bouchetou, and J. Poirier, “Corrosion en Phase Gazeuse des Réfractaires Alumineux dans les Fours de Cuisson d’anodes Destinées à la Production d’aluminium” (Presentation at Matériaux 2006, Dijon, France, 13–17 November 2006).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Prigent, P., Bouchetou, M.L., Poirier, J. et al. The effect of the addition of fine andalusite particles in refractory bricks on gaseous corrosion. JOM 60, 58–63 (2008). https://doi.org/10.1007/s11837-008-0061-8

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-008-0061-8