Abstract

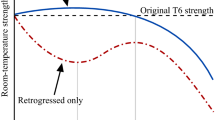

The retrogression and reaging (RRA) heat-treatment process and recent developments in high-strength 7xxx series aluminum alloys are summarized in this article. The results of experimental work indicate that RRA 7249 aluminum has the strength equivalent to or greater than 7249-T6 and superior corrosion resistance. This work is the result of collaborative efforts between the U.S. Navy and Loyola Marymount University.

Similar content being viewed by others

References

Kristen L. Deffenbaugh, “The Recent Developments of Modern High Strength Aluminum Alloys: A Closer look at 7150, 7249, 7055, 2097, and 2277,” unpublished report (2002).

W.H. Hunt and J.T. Staley, “High Strength Aluminum Alloys for Aerospace Applications,” Light-Weight Alloys for Aerospace Applications, (Warrendale, PA: TMS, 1989), pp. 111–120.

M. Garratt et al., “Materials Substitutions for Aging Aircraft: Extending Aircraft Life with New Generations of Alloys” (Paper presented at the 13th AeroMat Conference, Orlando, FL, 2002).

J.S. Robinson, D.A. Tanner, and S.D. Whellan, “Retrogression, Reaging, and Residual Stresses in 7010 Forgings,” Fatigue Fracture Engineering Material Structures, 22 (1999), pp. 51–58.

C.J. Peel and A. Jones, “Analysis of Failures in Aircraft Structures,” Metals Materials, 6 (8) (1990), pp. 496–502.

M.O. Spiedel, “Stress Corrosion Cracking of Aluminum Alloys,” Metallurgical Transactions A, 6A (1975), pp. 631–651.

M.U. Islam and W. Wallace, “Stress-Corrosion Crack Growth Behavior of 7475-T6 Retrogressed and Reaged Aluminum Alloy,” Metals Technology, 11 (1984), pp. 320–322.

B. Cina, “Reducing Stress Corrosion Cracking in Aluminum Alloys” (U.S. patent 3,856,584, 24 December 1974).

R.S. Kaneko, “RRA: Solution for Stress Corrosion Problems with T6 Temper Aluminum,” Metal Progress, 117 (1980), pp. 41–43.

M. Talianker and B. Cina, “Retrogression and Reaging and the Role of Dislocations in the Stress Corrosion of 7000-Type Aluminum Alloys,” Metallurgical Transactions A, 20A (1989), pp. 2087–2092.

J.K. Park, “Influences of Retrogression and Reaging Treatments on the Strength and Stress Corrosion Cracking Resistance of Aluminum Alloy 7075-T6,” Materials Science and Engineering, A103 (1988), pp. 223–231.

J.K. Park and A.J. Ardell, “Microstructures of the Commercial 7075 Al Alloy in the T651 and T7 Tempers,” Metallurgical Transactions A, 14A (1983), pp. 1957–1965.

J.K. Park and A.J. Ardell, “Effect of Retrogression and Reaging Treatments on the Microstructure of Al-7075-T651,” Metallurgical Transactions A, 15A(1984), pp. 1531–1543.

P. Fleck et al., “Retrogression and Reaging of 7075 T6 Aluminum Alloy,” Aluminum Alloys, Their Physical and Mechanical Properties—Proceedings ICAA7, Part 1 (Charlottesville, VA: Trans Tech Publications, 2000), pp. 649–654.

P. Fleck et al., “The Effect of Retrogression and Reaging on 7249 Aluminum Alloy,” Light-Weight Alloys for Aerospace Applications, ed. Kumar V. Jata (Warrendale, PA: TMS, 2001), pp. 99–108.

K. Koziar et al., “A Review of the Effect of Retrogression and Reaging on Aluminum Alloy 7249,” LiMat3 (Pusan, Korea: Center for Advanced Aerospace Materials, Pohang University of Science, 2001), pp. 559–564.

J.S. Robinson, S.D. Whelan, and R.L. Cudd, “Retrogression and Re-aging of 7010 Open Die Forgings,” Materials Science and Technology, 15 (1999), pp. 717–724.

J.E. Hatch, Aluminum: Properties and Physical Metallurgy (Materials Park, OH: ASM, 1984), pp. 47–3.

I. McCallum et al., “7150-T77511 Materials Qualifications for the P-3 Service Life Extension Program” (Paper presented at the 12th AeroMat Conference, Long Beach, CA, 2001).

D. Tenney et al., “7249-T76511 Materials Qualification for P-3 Service Life Extension Program” (Paper presented at the 12th AeroMat Conference, Long Beach, CA, 2001).

E. Colvin et al., “7249-T76511 Materials Qualification for P-3 Service Life Extension Program” (Paper presented at the 12th AeroMat Conference, Long Beach, CA, 2001).

Eui Lee et al., “On the Fatigue Characteristics and Fracture Toughness of T76, T6 and RRA Conditions of 7249 Alloy” (to be published in Journal of Materials Engineering and Performance).

M. Iskandar et al., “The Effect of Varying the Solution Treatment Temperature, Natural Aging Treatment and Artificial Aging Treatment on the Mechanical Strength of 7249 Aluminum Alloy,” Aluminum Alloys, Their Physical and Mechanical Properties, ICAA8 (Cambridge, U.K.: Trans Tech Publications, 2002), part 2, pp. 1121–1126.

M. Iskandar et al., “On Identifying the Most Critical Step in the Sequence of Heat Treating Operations in a 7249 Aluminum Alloy,” Engineering Failure Analysis Journal, in press.

N. Keleshian et al., “On the Distortion and Warpage of 7249 Aluminum Alloy after Quenching and Machining” (to be submitted to the Journal of Materials Engineering and Performance).

MIL-HDBK-5G:3.7.77249 Alloy (1998), pp. 3–422a.

Author information

Authors and Affiliations

Additional information

For more information contact Omar S. Es-Said, Mechanical Engineering Department, Loyola Marymount University, 7900 Loyola Blvd. Los Angeles, CA, 90045; (310) 338-2829; fax (310) 338-2391; e-mail oessaid@lmu.edu.

Rights and permissions

About this article

Cite this article

Es-Said, O.S., Frazier, W.E. & Lee, E.W. The effect of retrogression and reaging on the properties of the 7249 aluminum alloy. JOM 55, 45–48 (2003). https://doi.org/10.1007/s11837-003-0194-8

Issue Date:

DOI: https://doi.org/10.1007/s11837-003-0194-8