Abstract

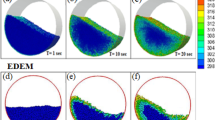

Experiments were conducted to demonstrate the effects of the drum wall temperature on the heat and mass transfer in rotary dryers. The drying characteristics of flexible filamentous particles in rotary dryers were further explored. In addition, the inlet and outlet temperatures and moisture contents of granular particles were measured. As a result, the good agreement between the simulations and experiments verified the rationale and feasibility of the numerical method. Therefore, the approach was adopted to evaluate the temperature and moisture content of wet granular particles in a rotary dryer in different conditions, for instance, drum wall temperature and rotational speed. The results revealed that the higher drum wall temperature led to hotter particles with lower outlet moisture content. Conversely, the higher rotational speed resulted in cooler particles with higher outlet moisture content due to the decrease of residence time in the rotary dryer.

Similar content being viewed by others

References

H. Herrmann, Physics World, 10, 31 (1997).

J. Bridgewater, Chem. Eng. Sci., 50, 4081 (1995).

Z. G. Huang and Z. H. Mao, Food Sci., 24, 185 (2003).

K. Di and J. Li, Cereal & Feed Industry, 12, 16 (2011).

C. W. Cao and W. X. Zhu, Computer simulation of agricultural drying process, China Agriculture Press, Beijing, 74 (2000).

J. Wang, S. J. Li and Y. C. Yang, Packaging and Food Machinery, 29, 44 (2011).

F.Y. Wang, I.T. Cameron, J.D. Litster and P. L. Douglas, Drying Technol., 11, 1641 (1993).

F.Y. Wang, I.T. Cameron, J.D. Litster and P. L. Douglas, Drying Technol., 13, 737 (1995).

F.Y. Wang, I.T. Cameron, J.D. Litster and V. Rudolph, Drying Technol., 13, 1261 (1995).

Y. Kaneko, T. Shiojima and M. Horio, Chem. Eng. Sci., 54, 5809 (1999).

J. Li, D. J. Mason and A. S. Mujumdar, Drying Technol., 21, 1839 (2003).

J. Li and D. J. Mason, Powder Technol., 3, 273 (2000).

K. S. Hatzilyberis, G. P. Androutsophoulos and C. E. Salmas, Drying Technol., 18, 2009 (2000).

M. Renaud, J. Thibault and P. I. Alvarez, Drying Technol., 19, 2131 (2000).

W. L. Vargas and J. J. McCarthy, AIChE J., 47, 1052 (2001).

L. P. Zhu, Z.L. Yuan and Y.M. Yan, CIESC J., 63, 2051 (2012).

L. P. Zhu, Z.L. Yuan and Y.M. Yan, CIESC J., 64, 2736 (2013).

H. L. Zhang, S.R. Yang and Z.M. Xu, J. Eng. Thermophysics, 26, 277 (2005).

C. H. Gu, X. Zhang and B. Li, Powder Technol., 267, 234 (2014).

F. Geng and Z. L. Yuan, Powder Technol., 193, 50 (2009).

J.G. Tong, Engineering Thermodynamics, Higher Education Press, Beijing, 58 (2007).

Z.G. Huang, H. Zhu and D. Li, Computer Simulation, 23, 330 (2006).

W. H. Zi, B. H. He and J. Liu, Journal of Kunming University of Science and Technology, 37, 85 (2012).

Z.G. Huang, D. Li and H. Zhu, Machinery Design & Manufacture, 1, 33 (2005).

H. Zarea Hosseinabadi, M. Layeghi and D. Berthold, Drying Technol., 32, 55 (2014).

R.M. Santos and J.W.P. Llanos, Drying Technol., 33, 37 (2015).

S. J. Friedman and W.R. Marshall, Chem. Eng. Process., 45, 482 (1949).

H. Abbasfard, S. Ghader and H. H. Rafsanjani, Drying Technol., 31, 1297 (2013).

H. Abbasfard, H. H. Rafsanjani and S. Ghader, Powder Technol., 239, 499 (2013).

GB/T21305-2007, Cereals and cereal products—Determination of moisture content—Routine reference method, Standards Press of China, Beijing (2007).

M. Eslamian, M. Ahmed and N. Ashgriz, Nanotechnology, 17, 1674 (2006).

M. Eslamian, M. Ahmed and N. Ashgriz, Drying Technol., 27, 3 (2009).

M. Eslamian, M. Ahmed and A. H. H. Ali, Drying Technol., 29, 1025 (2011).

G. M. Jin, Drying Equipment, Shanghai Science and Technology, Shanghai (2002).

K.Z. Ding, G.D. Deng and R. He. Acta Tabacaria Sinica, 3, 33 (2010).

C.W. Qiu, Technology and Enterprise, 8, 327 (2012).

J.F. Zhao, B. Li and W. K. Zhu. Manufacturing Technol., 6, 12 (2011).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Gu, C., Zhang, C., Zhang, X. et al. Modeling and simulation of drying characteristics on flexible filamentous particles in rotary dryers. Korean J. Chem. Eng. 34, 20–28 (2017). https://doi.org/10.1007/s11814-016-0224-1

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11814-016-0224-1